Ruger precision rifle .223 caliber, had 50 rounds loaded with 24 gns Varget with 68 gn HPBT bullets. All fired perfectly except for one. That one sounded and felt the same as the others and had the same point of impact. But when I went to open the bolt, it would not lift. After hitting it quite hard with the heel of my hand several times it finally lifted and I was able to eject normally. Cartridge looked normal with no flat primer or anything different than the others. Brass was Lake City. Any idea why this one round stuck?

Your load was a common across the course load, at least out to 300 yards. I would have not expected high pressures, but then, without pressure gages on your barrel, we really don't know what the actual pressure curve is in your rifle. What I am going to recommend is that you cut your loads by a half grain, and continue cutting by a half grain until all over pressure indications stop.

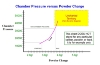

I would like to comment on the shooting communities attitudes on pressure. If the book value is lets say, 50,000, the majority of the shooting community believes each and every cartridge will be 50,000 psia. That is not so. You can look at SAAMI documents, but pretty much for ammunition, they allow an lot average of 50 kpsia (for example), but with 20% overs and unders. So it is perfectly OK if the occasional round hits 60,000 psia, as long as the average is 50 Kpsia. What that means to the hot rod community, the types who have to push things to the max, is that when they move the average pressure up, lets say to the 60 kpsia level, and assuming the 20% variance still holds at those pressures, then they are going to get the occasional 72 kpsia round, which happens to be above typical proof pressures. Proof pressures are kept just below material yield, so the hot rod types are clearly going to have the occasional round which is going to be at or above material yield. Since pressure data is scarce, it may be that when average pressures are pushed up, the variances also increase. At least on the high end. Gunpowder does not burn like a candle, nice and linear, it has an exponential slope to the curve. I am of the opinion that higher pressures will result in much greater high end variances, but without data I can't prove it.

Based on my decades of reloading experiences, I am going to say that pressure is not your friend. You are not the master of it, it will hurt you when it can, because it can. You get complacent with pressures and pressure will show you, that your complacency is all hubris and arrogance.

So, cut your loads. You had a high end pressure excursion that is telling you, your load is too hot with that combination of cases, bullets, powder, primers, and gun.