peterk1234

Member

- Joined

- Mar 20, 2017

- Messages

- 272

Hi guys,

I have been reading through the threads on the subject but decided in the end to ask the questions anyway. I have been loading 9mm, 38sp and 357 for a while now. I have about 40,000 rounds under my belt, so I am at least comfortable with the equipment I am using.

I am about to start reloading for 308. There are a couple of extra steps from what I have read, like reducing overall length, deburring and chamfering.

I have some questions about which press to be using and possible metering issues with some of the powders. I have a Hornady LNL and a Lee Turret. My Lee these days is only used for my 357mag loads(although the metering on it really sucks lately). Everything else in done on the LNL.

Does it make sense to use the progressive for rifle cartridges? Or should I use the Lee as a single stage? Also, I have been reading that my LNL may not cut Vardet and others very well, so metering will be a problem. That surprises me since the powder drop mechanism is metal inside of metal. Now I could see this as in issue on the Lee because there is plastic in there. Should I be doing my measuring and drop with something else?

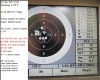

The rifle will be a bolt action (Howa 1500). Short range target for now (I only have a 100 yards to play with), but ultimately will be used for hunting when I retire and move to a normal State, or suck it up and go on a trip out West.

As always. Thank you.

Pete

I have been reading through the threads on the subject but decided in the end to ask the questions anyway. I have been loading 9mm, 38sp and 357 for a while now. I have about 40,000 rounds under my belt, so I am at least comfortable with the equipment I am using.

I am about to start reloading for 308. There are a couple of extra steps from what I have read, like reducing overall length, deburring and chamfering.

I have some questions about which press to be using and possible metering issues with some of the powders. I have a Hornady LNL and a Lee Turret. My Lee these days is only used for my 357mag loads(although the metering on it really sucks lately). Everything else in done on the LNL.

Does it make sense to use the progressive for rifle cartridges? Or should I use the Lee as a single stage? Also, I have been reading that my LNL may not cut Vardet and others very well, so metering will be a problem. That surprises me since the powder drop mechanism is metal inside of metal. Now I could see this as in issue on the Lee because there is plastic in there. Should I be doing my measuring and drop with something else?

The rifle will be a bolt action (Howa 1500). Short range target for now (I only have a 100 yards to play with), but ultimately will be used for hunting when I retire and move to a normal State, or suck it up and go on a trip out West.

As always. Thank you.

Pete