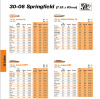

It lists COAL for M2 Ball as 3.340" and a powder charge of IMR 4895 of 50 grains. (MV 2740) That's well beyond any other published data I've seen.

Technical Manuals are not reloading manuals. That 50 grains happened to be the load for the day, with a lot of IMR 4895 that you will never, ever, buy off a store shelf. I don't know how many times this needs to be stated, but the powders you buy, on the shelf of a store, have been blended to meet a standard pressure curve by weight. To achieve that, powder sellers blend fast and slow lots of powder. Powder manufacturer is too imprecise to have a consistent product rolling off the end of the production line.

In fact, getting on my soap box, consumers are absolutely unaware of the amount of blending that goes on for their food and drink products. Even single malt Scotch is blended, your wines, drinks, mustard, honey, olive oil, ketchup, chocolate, etc, are all blended to a consistent taste and texture. People are so removed from the farm that they think every mustard plant produces the same mustard intensity. Nope! (try

Kampot pepper, the stuff has a flavor not found anywhere else) Just take the number of products you know are not blended, and divide them by the number of products that are blended, and see if the result comes out close to zero!

Also, the velocity quoted in those TM's are based on a Frankford Arsenal pressure barrel, not a Garand barrel. I learned that from a lot acceptance sheet for WC852. The buying agent from the Government took a calibrated cartridge from Frankford Arsenal and using that, adjusted the pressure and velocities reading from the vendor's pressure barrel. You want malfunctions in your Garand, you stick 50 grains of IMR 4895 in the case, and try to push a bullet to 2750 fps. You are better off keeping 150 grain velocities between 2650 fps and 2700 fps, with lower being better. Faster is never, ever better in a Garand.

You want to crack the rear heel of your Garand, just load them hot baby!

The owner of that receiver said that it cracked with HXP Greek 30-06. Some of that Greek ammunition was pretty old and had pressure spikes.

this was a receiver on Gunbroker, either hot loads, or a slamfire did this

The Government had pressure barrels and chronographs at their reloading plants. I met at guy whose job at Badger Arsenal was adjusting the charge weights for cartridge reloading. The Government bought powder in 90,000 pound lots, and during the Vietnam war, they had train loads of 90,000 lb powder lots at the loading dock, and each lot had to be velocity and pressure tested because each lot was different. The Government did not have to pay extra for the powder manufacturer to blend the powders they received, with their acceptance criteria (the Government did not accept every lot of IMR 4895, some were too slow or too fast) the Government took the lots they received and figured out just how much powder produced how much pressure and gave how much velocity.