Doindia

Member

- Joined

- Jul 24, 2020

- Messages

- 26

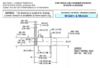

Hey all, I am new into reloading. I was always told the best way to learn how to reload is to reload with someone with experience. Apprentice so to speak. Unfortunately I have not been afforded that opportunity and I’m doing this off of instructions/manuals/YouTube. I have reloaded and shot about 20 rounds that all shot great. Seemingly accurate and without issue. My problem is hopefully easily depicted in the pictures below. My finished product has an uneven/taper/bow in the casing. I thought the problem started at the neck expansion but I’m not so sure anymore. I’m expanding the neck just enough so the bullet doesn’t tumble out, but even then it already looks like it has a lot of flare from where it started. So I took it back yet another process to the very beginning. It appears as soon as I deprime and resize my casing with the Lee 9mm die set the casing immediately has a visible and measure-able taper. At first I didn’t recognize it because it was so slight. I put the calipers on it and the top of the case measures 0.3725 and at the bottom of what I thought should be a straight case it measures 0.3885, so out of the gate I’m creating this taper with the resizing die. Additionally my inner neck where the bullet seats measures 0.3475. To be clear these are the measurements of a straight case 9mm after the resizing depriming die. Next I set up my neck expander to accept a bullet just enough to where it can sit in the mouth and not fall out. As soon as it comes out of the neck expander the case is starting to look pretty manipulated in the sense that it started as a straight case, I tapered in with the resizing die and now I’m expanding the neck back out. Once I seat and crimp the bullet I am left with the wavy type bulge at the top of the case, then what looks like a taper inward like an hour glass then back out at the bottom.

I am doing this on a lee 50th anniversary breech lock single stage press. I am using once fired brass that I have tumbled and polished in corn cob media. My bullets are .355 although i do not have a brand. I am using 4.4 grains of unique and a 115g bullet (although this happened to the 124 grain bullets as well. I am setting up my carbide dies exactly how the instructions as well as a few YouTube video showed me. I have used the lee lube that comes in the die set as well as no lube at all on a few and the end product is still the same.

Kind of at a loss here any guidance or direction would be greatly appreciated. I am going to try to follow up with pictures if I am able to.

I am doing this on a lee 50th anniversary breech lock single stage press. I am using once fired brass that I have tumbled and polished in corn cob media. My bullets are .355 although i do not have a brand. I am using 4.4 grains of unique and a 115g bullet (although this happened to the 124 grain bullets as well. I am setting up my carbide dies exactly how the instructions as well as a few YouTube video showed me. I have used the lee lube that comes in the die set as well as no lube at all on a few and the end product is still the same.

Kind of at a loss here any guidance or direction would be greatly appreciated. I am going to try to follow up with pictures if I am able to.