Erief0g

Member

So.. musing along today I pondered this. And before I delve to the question I'll admit I'm still a new reloader. At 49 years old I"d say I've only been reloading five or six years.

I've never chased max power in my reloads. I have taken my rmr 44mag plated bullets to their recommended max 1300fps but other than that nothing near max.

As I consider working up some loads with my rmr mprs I plan to bump them up to decent speeds i wondered about pressure.

To my question... pressure signs are often stated to be way over pressure before actually seeing the signs of over pressure.

Q1) Do we determine max pressure then based on velocity and our loading manual numbers? This topic needs a grain of salt as I'm not chasing max and not recommending it, just more understanding.

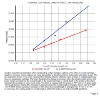

Example would be the snip pic from Alliant load data. Say we had the exact bullet listed in the load which it doesn't specify, but for arguments sake, let's assume the exact bullet. We see that listed max for this bullet is 4.7 gr at 1140fps with a four inch barrel at specified oal.

Can we extrapolate that if we reach this speed with our chronograph then we have reached max? This would apply even though changing the barrel length or possibly the cartridge oal?

I've got a bit more thoughts on this but figured I'd get some input first.

I've never chased max power in my reloads. I have taken my rmr 44mag plated bullets to their recommended max 1300fps but other than that nothing near max.

As I consider working up some loads with my rmr mprs I plan to bump them up to decent speeds i wondered about pressure.

To my question... pressure signs are often stated to be way over pressure before actually seeing the signs of over pressure.

Q1) Do we determine max pressure then based on velocity and our loading manual numbers? This topic needs a grain of salt as I'm not chasing max and not recommending it, just more understanding.

Example would be the snip pic from Alliant load data. Say we had the exact bullet listed in the load which it doesn't specify, but for arguments sake, let's assume the exact bullet. We see that listed max for this bullet is 4.7 gr at 1140fps with a four inch barrel at specified oal.

Can we extrapolate that if we reach this speed with our chronograph then we have reached max? This would apply even though changing the barrel length or possibly the cartridge oal?

I've got a bit more thoughts on this but figured I'd get some input first.