Grayrock

Member

I mic'd it last night. From round side to round side it showed approximately 0.357". From flat spot to round it is 0.347".

Fiocchi just decided to call them 38 S&W SHORT.

I just slugged one of my Police Positive Specials. I was a bit surprised that the groove diameter is kind of tight for 38 Special, about .355.

These were 9mm bullets, to match the 0.355" bore (yes, 0.355", what was Colt thinking?)

Driftwood,

I never thought I would see the day I would say something like this but I think what you said about the front sight is not exactly true. At least on every Iver Johnson I’ve ever examined closely, the front sight is actually a separate half moon shaped piece with a little bit of a key or flange on the bottom, and is pressed and probably soldered into place generally. I’ve never seen a front sight that was actually integral to the barrel on this type of Iver Johnson.

That said, bending on it will dislodge it from its staking/solder without much effort so if you choose to attempt to bend it from where it is, use caution.

I wonder how this got started/ My speer number 3 number 3 manual from 1959 and is still in my most recent edition -number 14 from 2007 It has this misinformation and it seems set in concrete in the gun press.

I have read many times over the years that Colt .38 barrels were smaller groove diameter than Smith.

It would be instructive to slug some WWII contract guns, the .38 Special US secondary standard revolvers and the .380 Revolver/.38-200/.38 S&W BSRs of both makes. Colt did not make nearly as many revolvers as Smith, being that they had lots of business for 1911s.

I still think that even if the bullet stuck solid at the muzzle the pressurized gasses would

1. Have plenty of expansion space behind the bullet

2. Have plenty of space to escape between the rear of the barrel and face of the cylinder.

I don't think the bullet will stick in the muzzle. We shoot squishy lead bullets, not steel bullets machined to fit snugly in the barrel. (I'd also not use jacked bullets, at least to start; and a long string around the trigger maybe too)

If you wanted to fix it, you could try using a steel rod of the proper diameter to iron out the dent. I'm not sure if you could do it without a hydraulic press, but I've seen videos of folks fixing dented pistol barrels.

Again, I'm still not sure this is the right thing to do, but I'd probably give it a shot before giving up and making a wall-hanger out of it.

Not a WWII contract gun,

ThYup, I just checked my Speer #13 manual which was printed in 1998, and it too lists the 38 Special as having been introduced in 1902. And as I said before, Cartridges of the World got it wrong too. Perhaps because 1902 was the year the 38 Military and Police 2nd Model (Model of 1902) was introduced.

Roy Jinks told me this 38 Military and Police 1st Model (Model of 1899 Army Navy Revolver), left the factory in 1899. It has a very low serial number, less than 200. It is chambered for the 38 Special cartridge.

View attachment 1027732

The 38 S&W came out in the 1870s for Smith and wesson and other pocket revolvers. The prefered bullet diameter is said to be .360 instead of the .357-8" of the 38 special and this seems to be the case with most Iver Jonnsons, H&Rs and other Massachusetts companies It is true of the Smith and Wessons as well. I was able to find a source of cast bullets of that diameter for my .38 Smith and Wessons and was surprised to learn that Colt- (Police Positive ) has the same bore diameter as the Special and is happy with either one.

Interestingly enough, this one is not marked for caliber, but a 38 Special fits perfectly.

In his 1977 book History of Smith and Wesson, Roy Jinks describes how this revolver was originally designed for the 38 United States Service Cartridge (38 Long Colt). But the cartridge had developed a reputation for poor stopping power. Daniel Wesson suggested to his son Joseph, that the cartridge be lengthened to increase the powder capacity from 18 grains to 21 1/2 grains and the bullet weight be increased from 150 grains to 158 grains. The new cartridge was called 38 Smith and Wesson Special. Although 1000 of this model were shipped to the Army and 1000 to the Navy in 1900, all chambered for 38 Long Colt, the commercial versions were chambered for either 38 Special or 32-20.

Here is a scan from my reprint of the 1900 S&W catalog, showing the new revolver. Notice the lack of a latch under the barrel for the front of the ejector rod. That did not come until the Model of 1902.

View attachment 1027733

Here is the page again showing the specifications of cartridges for the Model 1899.

View attachment 1027734

The reason I said WWII was because they were making a lot of guns for both cartridges and I thought it would be interesting to know if they made a difference in the barrels in wartime conditions.

I just slugged a Colt Police Positive Special that shipped in 1952. Not a WWII contract gun, a commercial model. The slug came out at .354 from groove to groove.

I have not fired this revolver in a long time, but I'm sure I was putting commercial 38 Special ammo through it years ago without any problems.

The reason I said WWII was because they were making a lot of guns for both cartridges and I thought it would be interesting to know if they made a difference in the barrels in wartime conditions.

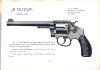

Did they make a version with a longer barrel?View attachment 1027829

As far as I know this is the last commercial revolver produced in 38 S&W .. 1986 .. I could be wrong… but its the last I know of .. I have owned a few over the years .. seemed to be a well made revolver.. Back in the day ammo could be found in local community general stores .. Buffalo Bore makes a nice load for the 38 S&W

Be sure you are wearing a steel gauntlet and your insurance is paid off before you try this. Personally, I would not try it.

Have you (or anyone else here, for that matter) seen any revolver "kabooms" from a bullet lodged down the barrel? Again, I'm not saying that it hasn't happened, but since I've never seen one or heard of one, my initial impression is to say that it probably isn't going to happen. The revolver kabooms I've seen were from grossly overpressure situations blowing up the cylinder. One more time, I'm not claiming that it has never happened or that it couldn't happen, but I don't believe this would be the failure mode this revolver is most susceptible to.

Howdy

How about this:...

I have one 38 Special Smith that has a bulge partway down the barrel. Don't recall right now which one of my many Smiths it is, but I think it is a pretty old one, probably from the 1940s or so. The barrel has a slight bulge, barely discernible when running my fingers along the barrel, but clearly visible when looking down the bore with a bright light. Don't remember right now just where in the barrel it is, probably 1/3 of the way from the cylinder. Most likely caused by a bullet stuck in the barrel, long before I owned it. No problem shooting that revolver, bullets skip right past the bulge. So that one did survive a bullet slamming into one stuck in the bore.

Sorry not to get back sooner, and thank you for responding thoughtfully. I hope this answer is as thoughtful as yours.

Your example(s) seem to agree with my point. First, it isn't the first shot that blows up the gun, it is the second after a squib. I think we are not dealing with squibs, and during test fire the arm should be inspected after every shot. I certainly recommend nothing other than cautious testing. (I just wouldn't be too worried about blowing it up to test it at all).

Second, even if a light charge only makes it down the barrel 1/3 of the way to the muzzle, odds are that it will be enough to allow the gas (at least enough of it) from the second shot space to expand and time to escape through the cylinder/barrel gap. If the first test shot somehow sticks in the barrel in question(which I really doubt it would), this would be far safer than that .38 Special you've got. .38 S&W has lower pressure and lower propellant volume. Of course, the IJ revolver is built to contain the lower pressure, and the science of heat treating steel advanced miles between IJ and 1940s S&W. What didn't change is the density of steel, which means that any shrapnel from the revolver will have the same mass and less acceleration meaning less energy if it did fail. The difference in the volume of gas is also still relevant as the cylinder gap and bore volume are still the same size (okay, a couple of thousandths different diameter, but close enough to be nearly negligible). Considering that this is an IJ, the cylinder gap is actually probably more than your average S&W.

The Merwin/Hulbert revolver is a good example of the failures with which I was familiar. That's what I was thinking of as the major danger to a revolver. A massively overpressure situation at the cylinder. Another way of getting an overpressure situation at this point is to have a primer-only squib that sticks just clear of the cylinder. The drawing in the Kuhnhausen book looks like this failure mode with the topstrap getting launched into a low-earth orbit.

Thoughts? Objections?

I think a soft swaged bullet will squirt out of that ovalized muzzle without harm.

I would confirm every hit on target lest I should be wrong and it stick one.