You have to run them enough to determine the reliability of the pistol.

When this was new and unmodified, cartridges would jam on the breech face. Problem was a burr around the firing pin hole. I removed that burr with something and that problem was fixed. I am a believer in having a polished 1911 breechface. It does not hurt to take a brass bristle brush and scrub off Parkerizing, etc, that might be on the breechface of a new 1911.

View attachment 1116135

This RIA ejected magazines when new

View attachment 1116136

the magazine latch was either insufficient, or as I now suspect, held the magazine too high. As the slide went forward, the magazine was ejected down! RIA sent me a replacement, this was the old one

View attachment 1116137

Magazines sat in the pistol very low with the replacement mag release. Lots of clearance between bottom of magazine and bottom of grip. Also, I could feel a very distinct bump, bump, as cartridges fed into the chamber. If I reloaded the bullet several times, the bullet was shoved deeper into the case each loading. The bump, bump had to be the bullet hitting the feed ramp, and finally chambering.

Then one day, this happened. The round fired, the magazine and all its contents ejected, and I had a case with a blown case head in the pistol.

View attachment 1116138

View attachment 1116139

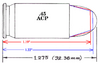

I did not know if it was my reloads or not. I chronographed and targeted the load, and it did not seem excessive. This is the load. A 230 FMJ leaving a five inch barrel at 805 fps.

View attachment 1116140

The pistol, once I racked the slide, the slide moved freely back and forth. My beautiful replacement coco bolo grips were cracked. The magazine base spring disappeared, and something hit my chin and caused a bruise, something hit the roof over the firing line. Gas release pushed the bullets into unfired rounds in the magazine. Since I had flying springs, bullets, I am glad I always wear glasses! Could have gotten something in the eyeballs. . Something that really helped me was the fact the bottom of the magazine was a piece of plastic and blew out easily. Quick gas release is important to keep pressures from building. If pressure builds, things can get worse. I might not have just cracked my cocobolo grips, but had them blown into my hand.

I field stripped the RIA, wiped everything out, and re-oiled. The slide racked, the hammer fell, the pistol was operable. This pistol is made of 4140 steel, and I am certain had I been firing some WW1 relic, made from un heat treated plain carbon steels, I could have ended up with a bulged or bent slide. But this thing, all I have had to do, is field strip, wipe out the powder residue, reassemble, and it functions. Today's guns are built much better.

After wiping and reassembly, I loaded up a different batch of ammunition and shot that. Everything worked. Because I was uncertain about the ammunition, it took time for me to shoot the kaboom batch up, but when I did, it all went bang. Because I was concerned that pressure might be high, or there was something wrong with the powder, I cut my loads by 3 tenths of a grain and shot an ammunition can of it. This reduced load has to be a mild load. I was very careful about my reloading procedures. This load went 715 fps.

View attachment 1116141

And what do you know, before the ammunition can of the reduced load was empty, I got a high pressure round. The primer flowed back into the firing pin hole, the case stayed on the bolt face, and the slide was jammed back.

That was when I decided that while bad reloads were still a could be, bullet set back was something to worry about, and fix. Due to case weight variations, it is fruitless to attempt to weigh pistol rounds. Loaded rounds vary more by four grains, so you are never going to catch a double charge, or an excessive charge, by weight. Fed the same bullet several times and the cartridge OAL lessens. I consider that risky. I purchased an

EGW higher magazine catch and installed it. I still get bullet set back, but overall, not enough to cause a high pressure incident. I still feel a bump-bump as the round feeds, but it is less pronounced than before. Keeping my fingers crossed, but I don’t shoot this pistol as much as I used to.

I am convinced the cartridge hitting the feed ramp/barrel and seating the bullet deep in the case caused my case head blowout. I am of the opinion that a good hard hit deep seated a bullet and the reduced case volume caused pressures to skyrocket. Since then, I am back to the full load of 230 FMJ with 7.8 grains AA#5 and shooting it in other 1911’s. The kaboom had nothing to do with powder deterioration or age. The powder is 1990’s AA#5 and I am making an effort to shoot up the keg as age wise, it is long in the tooth.

This pistol also has a very hard recoil, somewhere in the barrel lugh/slide stop geometry, the barrel lug parts from the slide stop early in the pressure drop, which causes high slide speeds at unlock. This is based on the analysis in this thread:

Old School Barrel Fit vs Modern Fit

https://www.bullseyeforum.net/t18500-old-school-barrel-fit-vs-modern-fit

My RIA eats shock buffs like candy. I believe this also translates to a high slide return. And, this pistol is very hard to shoot well. I have installed very powerful recoil springs, the strongest mainspring I could find, and at the suggestion of

@Steve in Allentown installed a flat bottomed slide stop. The flat bottomed slide stop needed to be fitted, and I could tell the extractor was clocking due to belling in the slide stop notch on the extractor. I don’t think the extractor is clocking now, and the cartridge ejection pattern is more consistent, and the brass does not go as far with a heavy recoil spring, heavy mainspring, and the flat bottomed slide stop.

Rock Island states FMJ only, and they are right, the barrel fouls excessively with lead bullets. I have gone through two bullet grit polishing sessions, and probably a 1000 rounds plus of FMJ, and the tube is brighter. There is still jacket fouling which takes JB Bore past to remove. If I shoot lead, it leads excessively, but less than before.

In comparison, these other bargain basement brands 1911’s have been trouble free and fun to shoot.

View attachment 1116142

View attachment 1116143

View attachment 1116144

View attachment 1116145

View attachment 1116146

View attachment 1116147

View attachment 1116148

Every bargain basement 1911 was the “best of three” for fit and trigger. I brought an oil bottle in for the Charles Daly and the Tisas and oiled the slide rails, hammer hooks, end of muzzle, and barrel hood and locking lugs. I racked the slide enough to get a feel of the smoothness, pressed on the muzzle and barrel bushing, back of the barrel with the hammer forward, when the slide is in battery, tried to rock the slide on the frame, and of course tested the hammer pull. I am impressed with the fit of these, they are better than the series 70 and 80 Colt NM pistols from the 1990’s and earlier. These have the tightness that it used to take a gunsmith to achieve by peening the slide rails. And filing barrel bushings to fit, cutting the barrel lug to a perfect fit, etc. Slide stops are all loose but I can fix that. Rounds are ejected in a 360 sphere, some bounding off me when I shoot. Takes forever to find my brass.

My Les Baer wadcutter will eject all cases into my shooting net. A high end 1911 will spoil you.

View attachment 1116149

I have been very pleasantly pleased in the reliability of the Tisas, Charles Daly, and ATI with my assortment of crap GI magazines, bargain basement new magazines, etc. My good magazines are being used in pistol matches. I am surprised how well my KCI bargain basement magazines are doing, I hope they keep on running.

A new owner of a 1911 should shoot the thing enough with the magazines he plans to carry, until he is convinced of the reliability and accuracy of the thing. New 1911’s can be finicky about magazines and bullets, and that has to be determined at the firing range. The Charles Daly and my Remington R1 1911 do not like my 230 LRN loads. I loaded these cartridges to 1.250 OAL but the slides won't close fully. Pushed the bullets in to 1.245" and the same cartridges feed like a champ in these pistols. These are things you have to find by shooting.