Greetings-

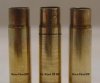

I recently picked up a new 300blk Forster full length bench rest sizing die, as I was unhappy with the lee sizing die I have been using the last six months or so. After trimming the Forster sized brass down to .360, I noticed the necks look much shorter than those from the lee die AND the primed AAC factory brass I picked up when it was first released. I checked many pieces, multiple times, and also ensured the sizing die was correctly setup. What's up with the massive difference in shoulder height/neck length (Forster on left, AAC factory on right)?

I have never seen such a large difference between sizing dies, prior to this. Thank you in advanced for your help....as always, I really appreciated it!

I recently picked up a new 300blk Forster full length bench rest sizing die, as I was unhappy with the lee sizing die I have been using the last six months or so. After trimming the Forster sized brass down to .360, I noticed the necks look much shorter than those from the lee die AND the primed AAC factory brass I picked up when it was first released. I checked many pieces, multiple times, and also ensured the sizing die was correctly setup. What's up with the massive difference in shoulder height/neck length (Forster on left, AAC factory on right)?

I have never seen such a large difference between sizing dies, prior to this. Thank you in advanced for your help....as always, I really appreciated it!