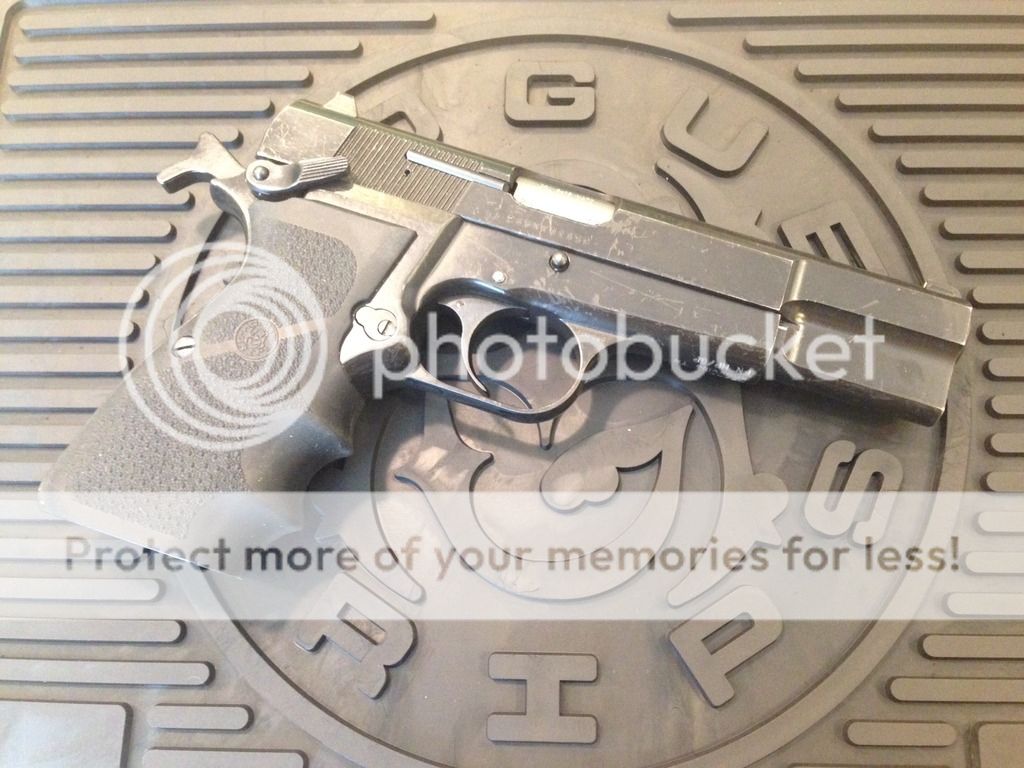

Well I got it installed after a lot of fiddling. I got a crappy ambi safety from Numrich and I had to fit the frame boss on the safety before it would even enter the frame, then had to fit the shaft of the safety before it would even enter the hammer, then had to carve and file down the right grip for the stupid ambi safety tab and body, and then had to fit the front portion of the sear shelf stud thing so it wouldn't interfere with the forward frame hole... but it's working, if quite stiff. (still more functional than the basically useless OEM safety which is so stiff it can't be used one handed or quickly.) This type is the common 1911 style with a split/keyed shaft rather than the Browning type that is a complete shaft with the right side lever pinned on (which I would prefer). The safety moves freely with just the hammer installed, and moves freely within the hammer hole, but once everything is put together it drags quite a bit. The sear doesn't move at all with the safety on, so that much is good.

What should I look at next? I fear the tolerances are just off somewhere and the shaft is warped so that when it's all buttoned up it's just binding somewhere.

I was able to do it without creating a hammer holding tool but I will definitely make one for the next go round.

Weird thing is the OEM safety does the same thing. Moves freely when in the frame alone, moves freely in the hammer, and moves freely when just the hammer is installed... but when all parts are in place it is very stiff.

Ideas welcome.