Mr. Farknocker

Member

- Joined

- Aug 13, 2011

- Messages

- 120

I need some advice on how to approach a problem that I have encountered while reloading for my 7.65x53mm Argentine Mauser.

The bore of my rifle slugged at a fairly large 0.3175' so I casted a few bullets using the Lee C324-175-1R (8mm Mauser) and sized them down to 0.319". Using the Lee die set, I then made a handful of brass cases with Winchester 270 brass. The shoulder length of the Lee dies are known to be too long for the Argentine Mauser (as opposed to Belgian) but I was able to push the shoulder back sufficiently by sliding a .013" feeler gauge under the rim while resizing the case. The bolt closed with only light resistance after the brass was resized using the gauge. I then made a dummy round by seating a resized bullet in an empty case. When I attempted to chamber the round, I could not close the bolt on the round. I made several attempts using several other rounds I made in the same manner and had the results.

I then resized the bullets to .314 and seated them in the cases. Unlike the first set of test rounds I made, I was able to chamber the round and close the bolt.

I measured the OD of the neck for the cases I loaded using the .319 resized bullets that wouldn't chamber and they measured .347".

I then measured the OD of the case necks for the rounds I loaded using the .314 resized bullets and they measured .345"

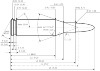

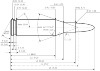

I then looked up the case dimensions for the round and found this graph:

The specs show that the maximum neck diameter is 8.78 mm or .3456" and explains why the round with a neck diameter of .345 chambered while the one that measured .347' did not.

Apparently, the bullet sized optimally to .319" (based on a bore diameter of .3175") expands the case too much while a bullet undersized to .314" doesn't.

Under the circumstances, it seems to me that I have a few options, none of which looks appealing to me:

1. Shoot undersized bullets and hope for the best accuracy one could achieve under the circumstances;

2. Have the chamber reamed to allow for the increase in the neck using a .319 bulle with no guaranty that the accuracy of the rounds will be any better than option 1; or

3. Have the barrel relined so that the bore diameter is line with specs and allows for the use of .313 rounds as recommended.

The first option appears to be a no-brainer as it costs me nothing to try and if it ends up shooting well -- end of story. However, if it doesn't, what would you recommend that I do?

The bore of my rifle slugged at a fairly large 0.3175' so I casted a few bullets using the Lee C324-175-1R (8mm Mauser) and sized them down to 0.319". Using the Lee die set, I then made a handful of brass cases with Winchester 270 brass. The shoulder length of the Lee dies are known to be too long for the Argentine Mauser (as opposed to Belgian) but I was able to push the shoulder back sufficiently by sliding a .013" feeler gauge under the rim while resizing the case. The bolt closed with only light resistance after the brass was resized using the gauge. I then made a dummy round by seating a resized bullet in an empty case. When I attempted to chamber the round, I could not close the bolt on the round. I made several attempts using several other rounds I made in the same manner and had the results.

I then resized the bullets to .314 and seated them in the cases. Unlike the first set of test rounds I made, I was able to chamber the round and close the bolt.

I measured the OD of the neck for the cases I loaded using the .319 resized bullets that wouldn't chamber and they measured .347".

I then measured the OD of the case necks for the rounds I loaded using the .314 resized bullets and they measured .345"

I then looked up the case dimensions for the round and found this graph:

The specs show that the maximum neck diameter is 8.78 mm or .3456" and explains why the round with a neck diameter of .345 chambered while the one that measured .347' did not.

Apparently, the bullet sized optimally to .319" (based on a bore diameter of .3175") expands the case too much while a bullet undersized to .314" doesn't.

Under the circumstances, it seems to me that I have a few options, none of which looks appealing to me:

1. Shoot undersized bullets and hope for the best accuracy one could achieve under the circumstances;

2. Have the chamber reamed to allow for the increase in the neck using a .319 bulle with no guaranty that the accuracy of the rounds will be any better than option 1; or

3. Have the barrel relined so that the bore diameter is line with specs and allows for the use of .313 rounds as recommended.

The first option appears to be a no-brainer as it costs me nothing to try and if it ends up shooting well -- end of story. However, if it doesn't, what would you recommend that I do?