So I started having failures to extract and failures to feed with a stock Glock 19 at my last shooting session.The issues were with 124g Xtreme HP and 115 Xtreme RN bullets. Mostly, the rounds would not fully feed into the chamber... if they did, a manual extraction by racking the slide was very difficult.

I figured that my OAL was too long since I load long for my CZ pistols. Usually about 1.15. Also, the same rounds that were hanging up in the Glock were running fine in my CZ Shadow and P01.

Back at the reloading bench, I shortened the OAL to 1.125 and it fixed the majority of my failures but still not perfect.

95% of the rounds pass the plunk test in the Glock barrel... but then I noticed that my press was not fully resizing the brass. I'm using a Dillon Square Deal B.

I did some research and it led me to changing the "toolhead friction plate"... it was very worn. Now my press is definitely resizing more of the case but there is still a good bit of case left untouched.

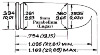

Check out the pictures for reference... is that gap normal? Is there anything further I can do to adjust the resizing on a Dillon Square Deal B?

I figured that my OAL was too long since I load long for my CZ pistols. Usually about 1.15. Also, the same rounds that were hanging up in the Glock were running fine in my CZ Shadow and P01.

Back at the reloading bench, I shortened the OAL to 1.125 and it fixed the majority of my failures but still not perfect.

95% of the rounds pass the plunk test in the Glock barrel... but then I noticed that my press was not fully resizing the brass. I'm using a Dillon Square Deal B.

I did some research and it led me to changing the "toolhead friction plate"... it was very worn. Now my press is definitely resizing more of the case but there is still a good bit of case left untouched.

Check out the pictures for reference... is that gap normal? Is there anything further I can do to adjust the resizing on a Dillon Square Deal B?

but at least it would all work when shot. Good luck.

but at least it would all work when shot. Good luck.