You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Powder dippers

- Thread starter Armored farmer

- Start date

- Status

-

Not open for further replies.

He used dippers and I always revert back to that. He never measured anything just dip and fire.What does the dippers have to do with over pressure loads? Why do dippers scare you? In most cases dippers are the most accurate and safest method of metering powders.

Never had good luck with the dippers or the perfect powder measure (700x powder doesn't meter well) so I found the Omega power trickler and use it for consistent reloads.

"Dandy Products Omega Powder Trickler is a revolutionary new way to trickle powder. Using an electronic control pad with a fast and slow speed it is able to trickle powder faster and more accurate than conventional tricklers. The Omega's hopper holds approximately 1000 grains of powder and is height adjustable for use on a wide variety of scales."

See it here: https://dandyproductsllc.com/ I have the "dandy auto trickler" works really well with my Dillion scale. Not super fast but allows me to put around 50 rounds of .38/.357 out per hour.

"Dandy Products Omega Powder Trickler is a revolutionary new way to trickle powder. Using an electronic control pad with a fast and slow speed it is able to trickle powder faster and more accurate than conventional tricklers. The Omega's hopper holds approximately 1000 grains of powder and is height adjustable for use on a wide variety of scales."

See it here: https://dandyproductsllc.com/ I have the "dandy auto trickler" works really well with my Dillion scale. Not super fast but allows me to put around 50 rounds of .38/.357 out per hour.

Mmm sweet relish...Then don't get into shotgun reloading .

View attachment 837322 my collection of volumetric bushings for my mecs

.308 Norma

Member

You can, and should use your scale anyway - at least occasionally, even if you're throwing charges from the finest powder measure money can buy. Or do you weigh every charge? Even if you do, how do you get your powder from its container to your scale?Quit using dippers 45 years ago. Even back then I never really relied on them , always used a balance beam and now electronic scale.

For weighing every charge, as I sometimes do when I'm working close to maximum, or when I'm working up a new load, I use a Lee powder dipper that dips a charge onto my scale that's just slightly less than what I want, then I use an RCBS trickle charger to bring the scale's balance beam up to 0.

But I stated earlier that I have two sets of Lee dippers - a "red" set and a "yellow" set. I've used my pocket knife to trim down some of the dippers in the "yellow" set until those dippers hold precisely (according to my SCALE) the amount of powder I want to use in a few of my favorite handgun loads.

Last edited:

JFrank

Member

Just to share an experience .

I use Lee dippers as I said earlier and then trickle to the exact number I’m looking for.

I once weighed several scoped and carefully leveled off 15 iirc , only 2-3 were Within .2 (no joy)

My BR charges must be within .1 for optimum performance.

I use Lee dippers as I said earlier and then trickle to the exact number I’m looking for.

I once weighed several scoped and carefully leveled off 15 iirc , only 2-3 were Within .2 (no joy)

My BR charges must be within .1 for optimum performance.

The type of powder and technique is huge for accuracy in dipping.Just to share an experience .

I use Lee dippers as I said earlier and then trickle to the exact number I’m looking for.

I once weighed several scoped and carefully leveled off 15 iirc , only 2-3 were Within .2 (no joy)

My BR charges must be within .1 for optimum performance.

Large extruded, or large flake powder must be weighed.

IMR 4227, titegroup, H110 and benchmark are on or minus one tenth.

Bluedot and greendot are within two tenths.

IMR4064, 3031, etc are scales only propositions.

The key is dipping, not scooping.

Don't look in a Lee load book.

l have a number of loads in various calibers listed as powder type and dipper volume.

Any new loads or cans of powder are verified with a scale first few dips.

None of my shooting involves a need of loading to the kernal of powder.

If you must weigh every charge go ahead, I don't judge just see no point in it unless loading top end loads.

l have a number of loads in various calibers listed as powder type and dipper volume.

Any new loads or cans of powder are verified with a scale first few dips.

None of my shooting involves a need of loading to the kernal of powder.

If you must weigh every charge go ahead, I don't judge just see no point in it unless loading top end loads.

Reloadron

Contributing Member

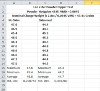

While I have assorted dippers laying around I don't use them for measuring powder charges. However, with dippers in mind I have a question which someone may have a credible answer to. Dippers rely on the VMD (Volume Measured Density) of the powder. Now kicking around a few numbers it becomes easy to derive a VMD for any powder. CC setting (powder measure setting) / Weight of the sample = VMD (volume in cc's for 1 grain) which is a pretty simple straight forward math formula. So with a known volume dipper and a scale we really don't need a chart since the VMD is easily calculated. While yes, it requires a scale it will give a good accurate VMD for any different lot of powder. This brings us to my question. Does the following hold true?

Does anyone know to what tolerance the powder making guys hold the VMD from lot to lot? I wondered if that 16% number is factual?

A few years ago I did a little kitchen table science experiment using a Lee Dipper and the Lee published data for H-335 powder. Here is how things went:

The expected target weight was 43.4 grains for a skimmed dipper. I was averaging a full grain over with an average of 44.7 grains. The dipper volume was checked weighing water so I know the dipper was accurate as to volume. Again, the VMD was not calculated but taken from the Lee VMD chart.

Ron

"It is very important that you repeat this process with any new container of the same powder because the powder companies allow themselves a 16% tolerance between batches. This can result in over charging if you work from the same setting and the next container of powder you get is more dense".

Does anyone know to what tolerance the powder making guys hold the VMD from lot to lot? I wondered if that 16% number is factual?

A few years ago I did a little kitchen table science experiment using a Lee Dipper and the Lee published data for H-335 powder. Here is how things went:

The expected target weight was 43.4 grains for a skimmed dipper. I was averaging a full grain over with an average of 44.7 grains. The dipper volume was checked weighing water so I know the dipper was accurate as to volume. Again, the VMD was not calculated but taken from the Lee VMD chart.

Ron

Attachments

Obturation

Member

I use them for loads that do not approach max and dont need to be ultra accurate. Mainly for trailboss cause it meters horribly through my powder dropper. Never had an issue, just make sure you have wiggle room and are not making anything near max.

FROGO207

Member

I have found that the Lee charts for volume are not all that accurate so weighing the scooped amount is a needed thing to do when setting up a load. But if you practice your scooping method then the amount is quite repeatable. I also make custom scoops using empty brass casings. I will weigh the charge and pour it into an appropriate casing noting how full it is. Dump out the powder. Then fill the brass with epoxy to use up the volume difference and a little bit more. Using a twist drill by hand after the epoxy sets I will slowly remove some epoxy until the scoop is the exact volume I want. Easy peasy! Make sure you solder the wire handle on BEFORE you fill it with epoxy. Don't ask how i know this.

.308 Norma

Member

Easy peasy! Make sure you solder the wire handle on BEFORE you fill it with epoxy. Don't ask how i know this.

JFrank

Member

Yep, that’s about what I came up with Varget powder.While I have assorted dippers laying around I don't use them for measuring powder charges. However, with dippers in mind I have a question which someone may have a credible answer to. Dippers rely on the VMD (Volume Measured Density) of the powder. Now kicking around a few numbers it becomes easy to derive a VMD for any powder. CC setting (powder measure setting) / Weight of the sample = VMD (volume in cc's for 1 grain) which is a pretty simple straight forward math formula. So with a known volume dipper and a scale we really don't need a chart since the VMD is easily calculated. While yes, it requires a scale it will give a good accurate VMD for any different lot of powder. This brings us to my question. Does the following hold true?

Does anyone know to what tolerance the powder making guys hold the VMD from lot to lot? I wondered if that 16% number is factual?

A few years ago I did a little kitchen table science experiment using a Lee Dipper and the Lee published data for H-335 powder. Here is how things went:

View attachment 837372

View attachment 837374

View attachment 837370

View attachment 837371

The expected target weight was 43.4 grains for a skimmed dipper. I was averaging a full grain over with an average of 44.7 grains. The dipper volume was checked weighing water so I know the dipper was accurate as to volume. Again, the VMD was not calculated but taken from the Lee VMD chart.

Ron

Pretty tough to get an accurate load being off as much as a full grain.

vaalpens

Member

- Joined

- Aug 14, 2014

- Messages

- 2,617

I still use my lee dippers when I work up a load. When I document my load in a spreadsheet it uses the VMD to calculate the volume and then I just use the closest volume dipper and the RCBS trcickler based on the calculated volume. I only load pistol load so I use my dippers mostly from .3cc up to ,7cc. My son has a 3d printer so he printed .4cc and .6cc dippers also for me. With the dipper I just want to get close and below the target weight, then trickle op to the target weight.

Edit:

Following are the dippers I used most. You can probably tell from the color which ones are used most.

Edit:

Following are the dippers I used most. You can probably tell from the color which ones are used most.

Last edited:

I use the Lee dippers when loading a few rounds of ammunition that is not "standard". Frequently, it is for loading shot loads or special, low quantity, loads.

In these cases, I weigh every charge.

When I got started in reloading several decades ago, I used Lee dippers with the Lee loaders. They worked well until I improved my process.

In nany case, I keep some dippers on hand.

In these cases, I weigh every charge.

When I got started in reloading several decades ago, I used Lee dippers with the Lee loaders. They worked well until I improved my process.

In nany case, I keep some dippers on hand.

ArchAngelCD

Member.

Oh boy, that is scary!He used dippers and I always revert back to that. He never measured anything just dip and fire.

IWAC

Member

When I loaded for rifles, I used the dippers to get a charge slightly lighter than I wanted, then my powder trickler to bring it up to the mark with my scale. Not fast, but plenty satisfactory for my reloading needs.

lightman

Member

I have not used dippers since I bought a ChargeMaster. Before that I used them to dump near charges into the scale pan. A powder measure would do the same job but the slide rule chart on the back of my Lee dipper box made the dippers faster.

I also have a set of homemade ones that I bought from a member on here, mostly for the "cool" factor. They were made from older cartridge cases, many of which were old rimfire cases.

I like your fix with the cartridge case!

I also have a set of homemade ones that I bought from a member on here, mostly for the "cool" factor. They were made from older cartridge cases, many of which were old rimfire cases.

I like your fix with the cartridge case!

1MoreFord

Member

I've never used powder dippers.

I started with a RCBS Rockchucker kit including the RCBS powder measure/dispenser and have not reverted from that combo. I have enough trouble trusting myself to dispense flour and sugar with a dipper/aka measure when cooking to trust myself to dispense a *near* explosive when reloading. YMMV

I started with a RCBS Rockchucker kit including the RCBS powder measure/dispenser and have not reverted from that combo. I have enough trouble trusting myself to dispense flour and sugar with a dipper/aka measure when cooking to trust myself to dispense a *near* explosive when reloading. YMMV

Dudedog

Contributing Member

Some Lee VMDs are close some are not.

I have found some powders are better lot to lot than others as far as actual VMD goes.

I used to always check when using the non adjustable disk measure.

(or at least in the lots of powders I have used)

I have found some powders are better lot to lot than others as far as actual VMD goes.

I used to always check when using the non adjustable disk measure.

(or at least in the lots of powders I have used)

Last edited:

1-12 INF (M)

Member

- Joined

- Jan 30, 2009

- Messages

- 132

I use the Lee dippers these days mostly for black powder. Then I switched to empty cartridge cases for BP loads and now fill them in bulk. The water volume of a given case is very close to the BP volume.

Old Stumpy

Member

- Joined

- Mar 3, 2019

- Messages

- 1,451

Before I bought a powder measure (a surprisingly long time) I used my scale to file-adjust homemade cartridge case dippers.

Being a contrarian I never did get around to buying a set of Lee dippers until after I bought my Redding Competition powder measure.

I never use them but they remain in reserve along with a stack of Lee Loaders that I also never use.

I also pick up near-new Lee Loaders at gun shows to supplement my dies, though they will never be used either.

Being a contrarian I never did get around to buying a set of Lee dippers until after I bought my Redding Competition powder measure.

I never use them but they remain in reserve along with a stack of Lee Loaders that I also never use.

I also pick up near-new Lee Loaders at gun shows to supplement my dies, though they will never be used either.

jhansman

Member

- Joined

- Mar 8, 2007

- Messages

- 1,113

I made a set from used rifle and pistol cases and heavy duty copper wire. It took some time to modify the cases to hold my favorite loads, but once that was done, soldering the wire handles to the cases was easier than I thought. Have recently moved over the Lee Classic Turret press with their Auto Drum powder measure, so my handmade dippers don't get much use anymore. Still, it was fun making them.

- Status

-

Not open for further replies.

Similar threads

- Replies

- 3

- Views

- 2K

- Replies

- 30

- Views

- 3K

- Replies

- 9

- Views

- 611

- Replies

- 14

- Views

- 880