Alaskan Ironworker

Member

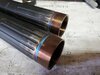

So I have this old Chilean mauser I picked up a few weeks ago, purely as a project gun. I finally had it pretty well cleaned up, checkered, de-rusted,(it had a lot!), trigger smoothed out as much as possible, but the military bolt bothered me. So I chopped it off with my porta-band. A had a nicely shaped bolt on some old mystery parts-bucket bolt as a donor to weld on. Ive never messed with welding on a gun before, but I do have thousands of hours stick welding under my belt, so I thought I’d give it a try. I used wet rags as a heat sink, tacked the bolt where I thought it should be and fit it into the rifle to check it for position. A small tack can be bent around a little without breaking to the desired position. After that I burned in the root pass in the deepest part of the bevel, let it cool, check for fit one more time, then flipped it over and back ground the underside of the root pass, and welded that. After that, I just filled up the rest of the bevel with tiny passes, cleaning really well and letting cool in between each pass. It kinda sucked with an A/C welder, but thats all I have at home, and it works good enough. I used 3/32” 7018 in the A/C variety. Im pretty happy with my first attemp. Still need a bit of sanding on the bolt. I should have taken more pictures of the process, was in hurry to get all the welding done before my kids got home.

)

)