None of my L-N-L shell plates for 45 Colt, 45 ACP, 44 Mag, or 41 Mag have the bevel that Reeferman is referencing. Some of the shell plates for smaller cartridges do have the bevel and all my shell plates have two detent balls. All of my shell plates were purchased after 2009 when I got my L-N-L press but that does not mean some were made before 2009.

I've never had to adjust the pawls on my press, never. The indexing is always spot on.

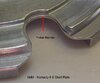

I have problems with the press ejecting 45 Colt cases. I made the modification described by Walkalong and it has helped but the jamming and tipping of cartridges has never gone away completely. I may need to extend the spring recess in the lifting plate a little more.

But, most, actually virtually all of my 45 Colt cases are R-P from the 1980's and the rim has a small bevel on the breach side of the rim. It looks like on some cases, the spring gets up under the case at this bevel between station 4 and 5 causing the case to tip.

I have the luxury of owning several different brands of progressive presses so I moved 45 Colt loading to a different press where the jamming is not an issue.