GunnyUSMC

Member

Don’t ask me why people do these sort of things. But if it weren’t for Bubba, I wouldn’t get to repair things like this.

This is the hand guard for the 03A3 stock that I repaired a few weeks ago that had been cutout for a turned down bolt handle. It had also been duffle cut. For some reason the hand guard had been cut also.

The stock belongs to Joe over at Aklys Defense.

It was on a rifle he has four sale. Joe asked me to repair the bolt cutout. When we took the rifle apart is when we found the poor attempt at repairing the duffle cut and hand guard.

Joe asked me if I could save it and I told him I would see what I could do.

The first thing was to decide on how the repair would be made. Basically clean it up, get it back together and reinforce it and hide the repair I decided to do the repair in three steps.

#1 Get it back together and straight. This includes making up for the saw cut.

#2 Reinforce the repair from inside.

#3 Blend the outside to hide the repair.

But first we need to clean it up.

The glue pretty much lost it’s grip due to the oil in the wood. ( Remember this. Wood glue on stock repairs = Bad Juju. ) The glue pretty much just flaked off.

I then soaked the ends in denatured alcohol to remove the oil from the area.

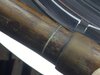

Here it is after the cleanup.

Found a small crack just to the right of the pin on the left.

Stand by for more.

Please forgive the mess in the background. I’ve been busy and my work bench is in a mess.

This is the hand guard for the 03A3 stock that I repaired a few weeks ago that had been cutout for a turned down bolt handle. It had also been duffle cut. For some reason the hand guard had been cut also.

The stock belongs to Joe over at Aklys Defense.

It was on a rifle he has four sale. Joe asked me to repair the bolt cutout. When we took the rifle apart is when we found the poor attempt at repairing the duffle cut and hand guard.

Joe asked me if I could save it and I told him I would see what I could do.

The first thing was to decide on how the repair would be made. Basically clean it up, get it back together and reinforce it and hide the repair I decided to do the repair in three steps.

#1 Get it back together and straight. This includes making up for the saw cut.

#2 Reinforce the repair from inside.

#3 Blend the outside to hide the repair.

But first we need to clean it up.

The glue pretty much lost it’s grip due to the oil in the wood. ( Remember this. Wood glue on stock repairs = Bad Juju. ) The glue pretty much just flaked off.

I then soaked the ends in denatured alcohol to remove the oil from the area.

Here it is after the cleanup.

Found a small crack just to the right of the pin on the left.

Stand by for more.

Please forgive the mess in the background. I’ve been busy and my work bench is in a mess.

Last edited: