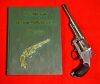

So here is a challenge for the knowledgable. The specific revolver is the H&A XL No. 8 introduced in this thread

https://www.thehighroad.org/index.php?threads/hopkins-allen-xl-no-8-army.880718/

So its 143 years old and in remarkably good shape. Rifling is very strong so I don't think there is a lot of wear in the bore/grooves. I sense that the below dimensions are what they were when the revolver was manufactured in 1877. Here are the dimensions that have me concerned:

- 6 grooves (so I should be able to measure it with a micrometer)

-Bore dimension 0.420"

- Groove dimension 0.438"

- Cylinder throat 0.426" (this is the smallest dimension in the cylinder closest to the barrel - throat may not be the correct term. Please correct as words have meaning and I'd like to not confuse the issue because I used an incorrect term)

- Forcing cone - I didn't measure the forcing cone because I really didn't know how to

As I see it the bullet will exit the cylinder sized to 0.426", enter the forcing cone and be forced into a bore diameter with part of the bullet in the groove staying at 0.426" leaving a space in the groove between 0.426" and 0.438" or 0.012"

The initial question is if a soft lead bullet will obdurate to fill the groove? How about hardcast as that is what is mostly sold today.

Knowing these dimensions does it matter the diameter of cast bullet I buy as they are all going to be around 0.429" + or - . I dont expect to find a 0.440 cast bullet and what good would it do as I see it the bullet is going to be 0.426 when it leaves the cylinder.

Background on this revolver/load. It was designed as a black powder cartridge firearm and I'm likely to load it in black powder mostly because I can and that is what it b.v was designed for. The local gunsmith believes it could handle the low pressure `Cowboy' loads. And by the heft and sizes involved I'm sure it could. Although if a low pressure smokeless load would bump up the bullet better, I'd consider it with enough research. Though I seem to remember that black powder will bump up the bullet better than most smokeless loads. I'd like your opinion on that aspect.

I've been loading for a lot of years but I know there is still a lot to learn. So I'm all ears.

https://www.thehighroad.org/index.php?threads/hopkins-allen-xl-no-8-army.880718/

So its 143 years old and in remarkably good shape. Rifling is very strong so I don't think there is a lot of wear in the bore/grooves. I sense that the below dimensions are what they were when the revolver was manufactured in 1877. Here are the dimensions that have me concerned:

- 6 grooves (so I should be able to measure it with a micrometer)

-Bore dimension 0.420"

- Groove dimension 0.438"

- Cylinder throat 0.426" (this is the smallest dimension in the cylinder closest to the barrel - throat may not be the correct term. Please correct as words have meaning and I'd like to not confuse the issue because I used an incorrect term)

- Forcing cone - I didn't measure the forcing cone because I really didn't know how to

As I see it the bullet will exit the cylinder sized to 0.426", enter the forcing cone and be forced into a bore diameter with part of the bullet in the groove staying at 0.426" leaving a space in the groove between 0.426" and 0.438" or 0.012"

The initial question is if a soft lead bullet will obdurate to fill the groove? How about hardcast as that is what is mostly sold today.

Knowing these dimensions does it matter the diameter of cast bullet I buy as they are all going to be around 0.429" + or - . I dont expect to find a 0.440 cast bullet and what good would it do as I see it the bullet is going to be 0.426 when it leaves the cylinder.

Background on this revolver/load. It was designed as a black powder cartridge firearm and I'm likely to load it in black powder mostly because I can and that is what it b.v was designed for. The local gunsmith believes it could handle the low pressure `Cowboy' loads. And by the heft and sizes involved I'm sure it could. Although if a low pressure smokeless load would bump up the bullet better, I'd consider it with enough research. Though I seem to remember that black powder will bump up the bullet better than most smokeless loads. I'd like your opinion on that aspect.

I've been loading for a lot of years but I know there is still a lot to learn. So I'm all ears.