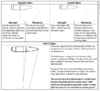

Again, new to reloading metalica, so trying to get up to speed on a variety of issues. One of the most confusing to me is consideration barrel twist to bullet selection. First became aware of it following a discussion on a different forum. Guy ordered a box of Sierra Match King bullets for 243.....95 grain. His complaint was he wanted to use them in a 243 Model 70 Winchester with 10:1 twist rate.....and Midway had failed to mention that bullet was recommended for 9:1 twist rate or faster.

Midway's info:

https://www.midwayusa.com/product/1482546904

Sierra's Info:

https://www.sierrabullets.com/product/243-caliber-95-gr-tmk/

This is a particularly good example, since the same caliber bullet could be loaded in at least 3 calibers I know of......244 Rem, 243 Win and 6mm Rem, plus probably many others, and from a wide array of bullets starting down in 50 grain range all the way up to 110 grains. Which one, however, is probably going to be determined by twist rate of the particular gun, with probably a wide overlap between them. As a guy new to all this probably something not stressed nearly enough.

Seems to be at least 3 or 4 different factors to consider.....in short, a lot of moving parts. Doesn't help that there are conflicting explanations, even from the experts. Case in point.......heavy round nosed bullets like Remington's Core Lokt soft nose. Have heard at least 3 explanations for that bullet design. My Lyman 50th manual mentions them, also mentions a "myth" about using them in brush. That was falling down funny, since that particular myth is exposed on a box of Remington Soft Point's I have where Rem themselves say guys use them in brush. But the best reason found is to shorten a heavy bullet so it will stabilize in barrels with 10:1 and slower twist rates.....got that one from a youtube expert. So who is right? Who is wrong? What are the facts? (rhetorical question)

But as for the concept, I think I'm getting there......current understanding is longer, heavier bullets for any given caliber need more twist to stabilize them in flight, are slower getting up to speed, so need a higher twist rate. One size does not fit all......too fast and a bullet will blow itself apart.

So what it seems to me is that despite all this wealth of reloading data, there needs to be a twist factor or coefficient developed for each bullet by caliber. Probably related length x caliber......maybe weight, but maybe not. Probably related to powder charge, velocity and pressure as well.

Or perhaps that is all implied when you go to the 244 Rem, 243 Win or 3mm Rem load data in the manuals? But even if so, it ought to be mentioned and discussed. In the above examples, I would think best results in 244 Rem would come from lightest bullets, 243 Win in the middle of the range and 6mm Rem going to the heavier range. And all tied back to twist rate of the barrels.

But are even those standard? Are all 243 Win sold with twist of 10:1? I don't know, but I doubt it.

Midway's info:

https://www.midwayusa.com/product/1482546904

Sierra's Info:

https://www.sierrabullets.com/product/243-caliber-95-gr-tmk/

This is a particularly good example, since the same caliber bullet could be loaded in at least 3 calibers I know of......244 Rem, 243 Win and 6mm Rem, plus probably many others, and from a wide array of bullets starting down in 50 grain range all the way up to 110 grains. Which one, however, is probably going to be determined by twist rate of the particular gun, with probably a wide overlap between them. As a guy new to all this probably something not stressed nearly enough.

Seems to be at least 3 or 4 different factors to consider.....in short, a lot of moving parts. Doesn't help that there are conflicting explanations, even from the experts. Case in point.......heavy round nosed bullets like Remington's Core Lokt soft nose. Have heard at least 3 explanations for that bullet design. My Lyman 50th manual mentions them, also mentions a "myth" about using them in brush. That was falling down funny, since that particular myth is exposed on a box of Remington Soft Point's I have where Rem themselves say guys use them in brush. But the best reason found is to shorten a heavy bullet so it will stabilize in barrels with 10:1 and slower twist rates.....got that one from a youtube expert. So who is right? Who is wrong? What are the facts? (rhetorical question)

But as for the concept, I think I'm getting there......current understanding is longer, heavier bullets for any given caliber need more twist to stabilize them in flight, are slower getting up to speed, so need a higher twist rate. One size does not fit all......too fast and a bullet will blow itself apart.

So what it seems to me is that despite all this wealth of reloading data, there needs to be a twist factor or coefficient developed for each bullet by caliber. Probably related length x caliber......maybe weight, but maybe not. Probably related to powder charge, velocity and pressure as well.

Or perhaps that is all implied when you go to the 244 Rem, 243 Win or 3mm Rem load data in the manuals? But even if so, it ought to be mentioned and discussed. In the above examples, I would think best results in 244 Rem would come from lightest bullets, 243 Win in the middle of the range and 6mm Rem going to the heavier range. And all tied back to twist rate of the barrels.

But are even those standard? Are all 243 Win sold with twist of 10:1? I don't know, but I doubt it.