Last year I recovered about 200 lbs. of wheel weights. After reading Glen Fryxell's From Ingot to Target, I figured I could make the WWs stretch out longer.

In chapter 3, http://www.lasc.us/Fryxell_Book_Chapter_3_alloySelectionMetallurgy.htm , he writes that more than 0.1% arsenic doesn't do any good. Wws on average contain about 0.3% arsenic.

My alloyed lead, 95-3-2, is 11-12 Bhn hardness with the pencil test. My WW alloyed with 2% tin is at 15 Bhn, after age hardening. If I mix the 2, at half and half, the mix is 15 Bhn after age hardening. That's at the same hardness as Lyman's #2, give or take.

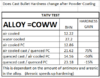

My next mix I'm going to mix small batch of pure lead with the WWs. At 97-2-1 and 0.1%, Fryxell's chart shows I can get 17-18 Bhn with age hardening.

The drawback of all this is the bullets will drop at a smaller diameter. But with powder coating, they should be okay.

BTW, have you seen how much tin has gone up? From the market chart I saw, it has nearly doubled since July of 2020.

In chapter 3, http://www.lasc.us/Fryxell_Book_Chapter_3_alloySelectionMetallurgy.htm , he writes that more than 0.1% arsenic doesn't do any good. Wws on average contain about 0.3% arsenic.

My alloyed lead, 95-3-2, is 11-12 Bhn hardness with the pencil test. My WW alloyed with 2% tin is at 15 Bhn, after age hardening. If I mix the 2, at half and half, the mix is 15 Bhn after age hardening. That's at the same hardness as Lyman's #2, give or take.

My next mix I'm going to mix small batch of pure lead with the WWs. At 97-2-1 and 0.1%, Fryxell's chart shows I can get 17-18 Bhn with age hardening.

The drawback of all this is the bullets will drop at a smaller diameter. But with powder coating, they should be okay.

BTW, have you seen how much tin has gone up? From the market chart I saw, it has nearly doubled since July of 2020.