Ranger99

Member

Something as simple as the plastic ammo box can leave a ring like that on brass.. . .

See this ^ ^ ^ all the time

Something as simple as the plastic ammo box can leave a ring like that on brass.. . .

I was laughing about this as my 308 now has a sizing ring at just the wrong spot that gives the appearance of this problem. I had inspected the brass 2 times already so I knew it was a non issue but another reloader at the range will be like hay bro.....See this ^ ^ ^ all the time

I think gas venting out the back is a near certainty in the case of a head separation. . . but there's very little chance of it (case head separation) hurting you.

You've provide a good example. The gas that cut those pits vented out the back. . . but your action includes sufficient gas management to spare you even noticing. Such had been my experience with head separations.My Rem 600 243 bolt shows pock marks for some defective primers, fired years ago. No gas hit me in the face.

You've provide a good example. The gas that cut those pits vented out the back. . . but your action includes sufficient gas management to spare you even noticing. Such had been my experience with head separations.

I may have one I can send you. Will have to look the next time I'm in my shop.If you find that they are bad I would love to get one for training, as I have never felt a bad one and I'd use it to learn.

I would not have though the breechface would survive intact long enough for the FP stop, 1.5" away, to erode that badly.. . . like this 1911 firing pin stop from shooting aluminum factory loaded cases. . .

So I just full-length sized a bunch of Remington .243 cases that have been reloaded once. The powder charge was near max, a couple tenths of a grain below where I had seen pressure signs when I developed the load. A few of the cases have a ring round them slightly more than half way from the head to the shoulder.

View attachment 988650

When I run a bent paper clip along the inside of the case wall it feels absolutely smooth. Should I be erring on the side of extreme caution and tossing these few that have the ring, or trusting my fingers that there is no serious defect?

When I run a bent paper clip along the inside of the case wall it feels absolutely smooth. Should I be erring on the side of extreme caution and tossing these few that have the ring, or trusting my fingers that there is no serious defect?

That won't hurt a thing except for a lost case, but the paper clip tells the tale. I cut cases to back up what I was feeling when I was learning.Cut one and see. Better to sacrifice one than a batch or your safety

One of the mods apparently mistook my last reply for sarcasm and derision and deleted it as inappropriate. No worries, and no offense taken. I apologize if my attempt at humorously complimenting a fellow forum member with a paraphrased quote from the movie 48 Hours was not well-written, so let me try again.Just curious.... @barnfrog what tool are you using to chamfer/debur? I used to get that ring a lot when I used the Lee hand tool to debur.

I have one question. Did you sharpen your paperclip? An unsharpened one can give a false negative.Thank you all. As usual, had I given it some thought I MIGHT have come up with the rather obvious idea of cutting one or two open to see what the deal is. I'll try to do that in the next day or two and post some pics. AJC1, you're more than welcome to any that have an actual defect.

I did not at the time, and fortunately it did not result in such a result as you indicate it could have. However, I have since sharpened it for future use.I have one question. Did you sharpen your paperclip? An unsharpened one can give a false negative.

I read that in a reloading manual. Since I'm here headed I had to test it.I did not at the time, and fortunately it did not result in such a result as you indicate it could have. However, I have since sharpened it for future use.

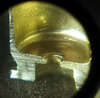

Since it's germane to the discussion... someone mentioned case head blowouts... this is what it looks like...

View attachment 1003337

View attachment 1003338

...and the cutaway...

View attachment 1003339

These were fired in my M1a... they blew the magazine out and left a pile of ammo and mag guts on my feet... but thankfully nothing else. After a LOT of discussion and debate, I have concluded the surplus brass was compromised in some way... either it was brittle to start, or it was exposed to something after it was turned in and sat that weakened the brass. This was LC 05, but I had the same type case head fracture in other headstamp LC brass, but from the same 'once-fired, processed' lot.

If it didn’t have any green, you’re likely OKMaking me wonder of the surplus brass I cleaned and if I might have a failure like that. Hmmmm.

This case broke through its case head during a 300 yard rapid fire in a NRA Across the course match. It blew out the magazine from the AR15. And this will bake your noddle, the next round fed into the chamber! The shooter was un injured, just the magazine was a bit mangled, and the rifle was shootable after the jam was cleared.

The case came from Scharch, it was from pull down military surplus.

View attachment 1003372

View attachment 1003373

View attachment 1003374

View attachment 1003375

Another shooter at the match told me he had similar problems with 5,56 military brass acquired from Scharch.

What I am going to say, the common thread is military pulldown brass. And I am going to claim, that the only reason the military culled that stuff from its inventory was because an Ammunition Technician had gone through that lot of ammunition and found gunpowder deterioration. It may have looked like this

View attachment 1003376

and it will lead to problems like this

View attachment 1003377

When gunpowder deteriorates it releases NOx, some of which is converted to NO2, nitrogen dioxide, and some of that will convert to nitric acid gas if it encounters a water molecule. Which there is some in the air in the cartridge case. And those reactive chemicals will cause brass to deteriorate.