You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are the thoughts on the new 6.8mm (.277) cartridges?

- Thread starter N9NWO

- Start date

- Status

-

Not open for further replies.

Any thoughts?

We already have 26 and 28 caliber cartridges that do the same things. This is just an attempt to give 27 caliber fans a round that will duplicate what is already being done. They are no better or worse, just in 27 caliber instead of 26 or 28.

While the 270 is a fine and classic hunting round both the cartridge and rifles have limitations with modern projectiles. It was really more by chance than by design but most of the 26, 28, and even 30 caliber rounds are better suited for them. For whatever reason the 25's and 27's were not. The newer 27 caliber rounds correct that. But it just seems a lot simpler for me to just use an established 26 or 28 caliber cartridge rather than reinvent the wheel.

KsSkaEnthusiast

Member

- Joined

- Jun 23, 2020

- Messages

- 241

As a member of the church of the .270, i am happy to see the new technology and adaptations drizzle into the 6.8 sector.We already have 26 and 28 caliber cartridges that do the same things. This is just an attempt to give 27 caliber fans a round that will duplicate what is already being done. They are no better or worse, just in 27 caliber instead of 26 or 28.

While the 270 is a fine and classic hunting round both the cartridge and rifles have limitations with modern projectiles. It was really more by chance than by design but most of the 26, 28, and even 30 caliber rounds are better suited for them. For whatever reason the 25's and 27's were not. The newer 27 caliber rounds correct that. But it just seems a lot simpler for me to just use an established 26 or 28 caliber cartridge rather than reinvent the wheel.

CapnMac

Member

The ammunition world has been chasing around a "super" cartridge in the 7x40 to 7x45 range for close to a century.

Every new cartridge is the best new sooper-dooper first bicycle bread slicer.

Every new cartridge is the best new sooper-dooper first bicycle bread slicer.

Captcurt

Member

I may have to get another 270. I have seen more bullets, brass and ammo for the 270 than any other caliber during this shortage. Sure, I like new stuff, but at what cost? The new offerings have very little advantage over the older ones. I might be giving up a couple hundred fps, but at least I can get the items I need to keep it in ammo. Try to find some of the oddball calibers now. They are not there and probably won't be for another year or two. Shot the old Winchester caliber for over 25 years and never needed more. I have never understood why the powers that be need to make a clone.

Mosin Bubba

Member

- Joined

- Jul 5, 2012

- Messages

- 1,936

Isn't the Fury loaded super hot, like 85k PSI? That's something new we haven't seen before.

earlthegoat2

Member

Next year it will be a 25 cal that gets “modernized”

Isn't the Fury loaded super hot, like 85k PSI? That's something new we haven't seen before.

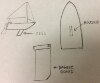

I have yet to up load the pictures I have, but the Fury has a steel head case, similar in concept to this:

What I saw of the Fury was a crimped, not threaded steel case head. I am going to wait a long time before I rush down to the store to buy a cartridge that runs at 85 Kpsia. There are too many unknowns about a weapon operating at those pressures, especially when it comes to pot holes in the road, so to say.

What we are reading about the current super duper 277 cartridges, the ones that are not operating at 85,000 kpsia, is all about super long range capability. The bullets are so long, so sleek, that you can shoot over the horizon. Bosh, few people are capable of hitting the berm at those distances, never mind a game animal. And then, those long shots are not in my area. Too many trees and under brush.

I have walked across many a farmers field, full of fresh deer tracks. But the deer walked across that field at night, and in the day time, they are bedded down in thickets worse than the picture above. They are not stupid, they know the habits of humans.

The extra long range capability is for Walter Mitty's. The superior accuracy at distance is probably there, but it will not be 100% better, the first shot is the one that counts, and no bullet made yet ignores the wind. While this is good enough for deer, you don't see the sighting shots that got me in the ten ring.

And, my rifle carries five rounds in the magazine, and it is flush to the stock. These super duper rounds, three rounds, or some box magazine that sticks down like a daggerboard.

From wiki

.

.Churning the market. It's riding the coattails of the proposed military round which may or may not ever be approved or used. The real tech to that is the use of a low or no brass case to minimize dependency on a resource, reduce weight, and eliminate forced recycling of it.

There is a sweet spot in cartridges from 6.5 up to 7.5 where you can get aerodynamic bullets and enough powder charge to cover a lot of bases, with fairly minimal recoil. It's .270's turn. Short actions allow a lot of leeway with them, it's an affordable class of hunting rifle and popular, too.

Beat by a minute, what he said ^^^

There is a sweet spot in cartridges from 6.5 up to 7.5 where you can get aerodynamic bullets and enough powder charge to cover a lot of bases, with fairly minimal recoil. It's .270's turn. Short actions allow a lot of leeway with them, it's an affordable class of hunting rifle and popular, too.

Beat by a minute, what he said ^^^

The barrel twist of the western and the few niche bullets that would actually utilize it are the only appeal, same as a custom .270/wsm with fast twist, same as a fast twist .250ai, except more recoil. Honestly I see nothing that can't be done with the 22, 24, 26, or 28s but that's not new, that's been the case since the first .22 beat .22 hornet speeds. Maybe we need a .23 and .29 to help out the oddballs.

Archie

Member

I do not see the reason for many 'new' rounds, other than a childish attempt by manufacturers to sell rifles.

The .277 Gee Whiz Umpah Whoopee may be just fine. What will it do that a 7x57mm Mauser in a modern action rifle will not?

Change is not mandatorily progress.

The .277 Gee Whiz Umpah Whoopee may be just fine. What will it do that a 7x57mm Mauser in a modern action rifle will not?

Change is not mandatorily progress.

someguy2800

Member

I like the 277 sig fury round with the steel case head. I think that is an innovation who's time has come.

cdb1

Member

I’ve been using a.270 since the early 70’s but for the past ten years use a 6.5x55 most of the time. Speaking only for myself, the 6.8 Western doesn’t do anything a .270 WSM won’t do. I also could care less whether a cartridge is LA or SA other than short fat stubby cartridges are more prone to feeding issues.

Nature Boy

Member

- Joined

- Apr 21, 2015

- Messages

- 8,244

My thought is the 6.8 Western is so close to the 270 WSM that I wonder why it was created in the first place.

My thought is the 6.8 Western is so close to the 270 WSM that I wonder why it was created in the first place.

The primary reason for the creation of cartridges is to increase profit for the gun industry. While every article claims there is some huge performance gap, just look at a Cartridges of the World, the paper back version is 688 pages, and make a case that there is some sort of a performance gap in the historical record.

I recently read a 6.8 Western article, and the primary difference between the 270 WSM and the 6.8 Western is that the Western has less case capacity, and the twist is faster. Is that enough to get buyers running screaming to the local gunstore? Probably. The cases could be identical, but they decided to tweak the thing.

The article on the 277 Fury did not address barrel life. I know shooters who ate up 264 Winchester Magnum barrels in 800 rounds. Their tubes keyholed because the rifling was gone for a foot or more in front of the chamber. Given an 85 Kpsia cartridge, I think it probable that barrel life will be 500 rounds.

There are real limitations for barrels that burn out quickly. An F class shooting bud of mine, he has some 6mm or 6.5mm 284 wildcat, and before he went to the F class National he had 400 ish rounds through the tube. Bud is a superior shooter, and his rifle shot well till it accumulated 1000 rounds total. Given all the individual and team events, his barrel hit 1000 rounds at the Nationals and at the end, his bullets were tumbling due to the lack of rifling! Bud's score went from top class, to the bottom of the list, very quickly. I did look at the results, his last scores were right there with the people who did not fire. It was humiliating, a total waste of time, and Bud was totally frustrated. He did say "the winner had over 2000 rounds on his barrel!"

For someone who got between 4000 and 5000 rounds on my 308 Win's shooting NRA across the course, I find it boggling that F Class shooters are getting less than 1000 rounds through their 308 Win barrels. But they are pushing 185's, 200's, and 220's, faster than I was pushing my 168's.

Archie

Member

Innovation? Are you speaking of the cartridge itself or the steel head? Depending on how they work, I could agree on the case structure. The first question in my mind is will the cases hold up to use, or will head separation be a problem?I like the 277 sig fury round with the steel case head. I think that is an innovation who's time has come.

I have to admit I'm wondering a bit about the 80,000 psi chamber pressure as well. Will a regular weight and profile action contain such pressure on a long term basis?

Then again, why? I don't see the utility for a hunter or ordinary user. For a sniper rifle, perhaps. Then again, I'm out of the sniper business for some time now.

Last edited:

Nature Boy

Member

- Joined

- Apr 21, 2015

- Messages

- 8,244

For someone who got between 4000 and 5000 rounds on my 308 Win's shooting NRA across the course, I find it boggling that F Class shooters are getting less than 1000 rounds through their 308 Win barrels. But they are pushing 185's, 200's, and 220's, faster than I was pushing my 168's.

I’ve got over 3k in my .308 shooting 185 Berger Hybrids and accuracy hasn’t fallen off yet. My daughter cleaned a 600 yard match with it a few months ago.

Innovation? Are you speaking of the cartridge itself or the steel head? Depending on how they work, I could agree on the case structure. The first question in my mind is will the cases hold up to use, or will head separation be a problem?.

For the Fury case design, we will see. But case head separation has always been an issue with two piece cartridges cases. The front sticks, and the joint fails. These are some historical and current designs.

these polymer cases, the case head is inside the polymer

these look interesting, I wonder how they are doing

based on what I have read, this works

but the case was designed so the front contracts so fast, and so much, that it does not drag on extraction. And that can be done with material choice and relatively low pressure cartridges. The regular 45 ACP does experience some drag on extraction, as evidenced by the soot and drag marks on these once fired cases.

N9NWO

Member

- Joined

- Apr 12, 2021

- Messages

- 145

https://sofrep.com/news/goodbye-m16-m4-and-helloooo-ngsw-r/Churning the market. It's riding the coattails of the proposed military round which may or may not ever be approved or used. The real tech to that is the use of a low or no brass case to minimize dependency on a resource, reduce weight, and eliminate forced recycling of it.

There is a sweet spot in cartridges from 6.5 up to 7.5 where you can get aerodynamic bullets and enough powder charge to cover a lot of bases, with fairly minimal recoil. It's .270's turn. Short actions allow a lot of leeway with them, it's an affordable class of hunting rifle and popular, too.

Beat by a minute, what he said ^^^

The first units will be equipped in February 2022. I do expect to see polymer cases

Archie

Member

That's what I was wondering. I am familiar with some of those. The only one that worked well was the shotgun shell, can't remember the trade name. It wasn't commercially successful. It worked, but didn't do anything better and (in my memory) cost more.For the Fury case design, we will see. But case head separation has always been an issue with two piece cartridges cases. The front sticks, and the joint fails. These are some historical and current designs.

I suppose some of the modern 'super glue' type adhesives would work.these polymer cases, the case head is inside the polymer

That strikes me as another problem. A significant portion of thrust is - as I understand - controlled by the cartridge case expanding again the chamber walls. At 80,000 psi, that might cause some problems requiring mechanical lockup to be stronger. Strikes me as demanding a certain action.but the case was designed so the front contracts so fast, and so much, that it does not drag on extraction. And that can be done with material choice and relatively low pressure cartridges. The regular 45 ACP does experience some drag on extraction, as evidenced by the soot and drag marks on these once fired cases.

No doubt all can be arranged. At what cost and convenience?

someguy2800

Member

Innovation? Are you speaking of the cartridge itself or the steel head? Depending on how they work, I could agree on the case structure. The first question in my mind is will the cases hold up to use, or will head separation be a problem?

I have to admit I'm wondering a bit about the 80,000 psi chamber pressure as well. Will a regular weight and profile action contain such pressure on a long term basis?

Then again, why? I don't see the utility for a hunter or ordinary user. For a sniper rifle, perhaps. Then again, I'm out of the sniper business for some time now.

The innovation is the case design to be able to run at a higher pressure. Safely adding an extra 20K psi over the normal is a paradigm shift because it means we can get the same muzzle velocity as we are accustomed to from a 24" 270 winchester in a 16" barrel with less powder. Cartridge case design for the last 130 years or so has basically been making the same thing just longer, shorter, fatter, skinnier, or different tapers. The steels that we have available now to build rifles has advanced tremendously, but for about the last 100 years the pressure ceiling has not been the strength of the rifle but the pressure that the brass cartridge case can hold. Yes it needs a lot of testing and validation to prove itself but surely the day will come when we advance past a design that has been static since the 1890's.

Jerry M

Member

My thought is the 6.8 Western is so close to the 270 WSM that I wonder why it was created in the first place.

Slightly shorter cartridge, (to seat heavier bullets outside the case) faster twist barrels; same thing that made the 6.5 Creedmoor 'better' than the.260 Remington.

That strikes me as another problem. A significant portion of thrust is - as I understand - controlled by the cartridge case expanding again the chamber walls. At 80,000 psi, that might cause some problems requiring mechanical lockup to be stronger. Strikes me as demanding a certain action.

The idea that cases are strong, and actions are weak, and that the case is supposed to carry load to reduce bolt thrust, is an Army coverup over a century old. In comparison, the Chinese COVID Lab coverup is a short term piker, and even less successful. Pre WW1 the Army was building M1903's in factories which the only recorded temperature gauge (a pyrometer) was used for heat treating springs. Every where else steel temperatures were judged by eye. This was a consequence of under funding, and a management that did not want to know, so they were in denial. When receivers, bolts were over heated, that is burnt, in the forge room, the heat treat ovens, etc, and these structurally deficient rifles parts got out into the field, and blew up, the Ordnance Bureau denied there was a problem. And created the misdirection that the receivers were blowing up because of greased bullets. The bullets were greased because grease prevented cupro nickle bullet fouling.

The smart shooter of the era purchased a grease filled tin, with a little hole for the bullet, and the shooter dipped the bullet in, gave a twist, and fired the round greased.

This is massive over greasing, but something I did .

one the left before, and on the right, after firing.

all greased and fired

and what is noticeable, is that grease flows down to the base, and the sidewalls are coated with grease. Obviously the case is not sticking to the chamber, the whole case is floating in grease.

When "perfect" Army rifles firing "perfect" Army ammunition blew up on the firing line, the Army blamed the grease. The logic is simple, rifles fragmenting on the line can't be due to anything the Army did.

Reminds me of what Boeing said about the two 737 MAX crashes. The planes were perfectly designed, and perfectly built, so the crashes had to be pilot negligence! . And if you are a Boeing employee, you agree, because you have drunk the kool aid. All human organizations believe their own propaganda. Those that don't drink the kool aid are cast from the kingdom.

Anyway, the idea of "increased bolt" thrust being a danger started then, and has been promulgated by generations of in print gun writers to hundreds of millions of shooters. The cover up has legs. But it is false.

the case is a gas seal, not a structural member. The case has to be supported or it will burst. That was an opps!

If the case is stretched, it will rupture. No one weakens an action assuming that the case takes some of the load. For example, what is that number? By how much would an action designer weaken his action, assuming that the case carries the rest of the load. And what happens if the round is wet, or the barrel is cleaned and oiled?

And, why would anyone want the case sticking to the chamber? If the case sticks, breaks the extractor, or rips the rim off, it has to be knocked out with a cleaning rod, or dowel. Not a good idea for a repeating rifle.

And surely, the sidewalls of those plastic cases can't take much thrust off the bolt, the joint will fail.

And what about caseless ammunition, surely that could not work, as there is no case to take the bolt thrust.

In my opinion, the 85 Ksia rounds are going to be trouble! Just take a look at the lower grade of steels and see what their yield strengths are, which is around 80 kpsia. So bolt lugs are going to have to be made of higher grade steels, which require strategic alloys, such as nickel, vanadium, molybdenum, etc, and that stuff comes over oceans, which during one war, was filled with U boats and sharks! Why would anyone assume that the oceans will be friendly in the next war?

Combining the industry capacity of China, with the raw materials of Russia, and the US will be starving for food and materials.

And, the receiver seats have to be built out of high alloy steels, and heat treated, so the fatigue life will be less. When steel is heat treated to be hard, it loses toughness. That results in a shorter time to failure with loading cycles. On the AR forum, one poster asked about bolt life, and a lot of AR15 bolts start cracking lugs around 10,000 rounds, some last 30,000 but they are made from special steels. I predict with 85 Kpsia rounds, the lugs will be cracking sooner!

Anyone remember those traffic classes we used to take, that had films titled "Speed Kills", or "Speed is not your friend"? Similarly, high pressure is not your friend either. The pressure curve has an exponential slope, and with cartridges running 85 Kpsia, I predict blown breeches and barrels when the pressure curve spikes due to temperature, fouling, old gunpowder, rat's nests in barrels, etc. Things go bad, a lot faster, at high pressures.

Last edited:

someguy2800

Member

In my opinion, the 85 Ksia rounds are going to be trouble! Just take a look at the lower grade of steels and see what their yield strengths are, which is around 80 kpsia. So bolt lugs are going to have to be made of higher grade steels, which require strategic alloys, such as nickel, vanadium, molybdenum, etc, and that stuff comes over oceans, which during one war, was filled with U boats and sharks! Why would anyone assume that the oceans will be friendly in the next war?

Combining the industry capacity of China, with the raw materials of Russia, and the US will be starving for food and materials.

And, the receiver seats have to be built out of high alloy steels, and heat treated, so the fatigue life will be less. When steel is heat treated to be hard, it loses toughness. That results in a shorter time to failure with loading cycles. On the AR forum, one poster asked about bolt life, and a lot of AR15 bolts start cracking lugs around 10,000 rounds, some last 30,000 but they are made from special steels. I predict with 85 Kpsia rounds, the lugs will be cracking sooner!

Anyone remember those traffic classes we used to take, that had films titled "Speed Kills", or "Speed is not your friend"? Similarly, high pressure is not your friend either. The pressure curve has an exponential slope, and with cartridges running 85 Kpsia, I predict blown breeches and barrels when the pressure curve spikes due to temperature, fouling, old gunpowder, rat's nests in barrels, etc. Things go bad, a lot faster, at high pressures.

It’s not 1930 anymore, the grade 8 bolts sold at the hardware store for $5/lb are 130,000 psi yield strength. We have steels now with well over 200,000 psi yield strength. The steels that they used to build 1903’s out of would not pass for rebar today.

Last edited:

- Status

-

Not open for further replies.

Similar threads

- Replies

- 59

- Views

- 9K

- Replies

- 102

- Views

- 6K

- Replies

- 57

- Views

- 7K