CoRoMo

Member

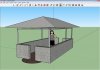

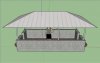

See the attached picture and note the ground depth indication I drew. Borrowed the photo from someone on Arfcom (will return it when done).

I'm going to build a little building like this, but I'm not going to use wood throughout as this one pictured was made. I'm using a bunch of 6 gauge angle iron for most everything, but the floor will be wood framed and either planked or sheeted.

The floor will not float as high off the ground as this pictured one does, I want mine to have only 6" or so between the ground and the bottom of the 2x6 and 2x4 floor joist frame. So the floor level will be approx 12" above ground.

Ceiling height at the front will be 7' and 6' at the back, so a 12" total roof elevation/slope.

Two rifle benches on the left and two pistol lanes on the right.

I basically just don't want a big wind during any thunderstorm to take this thing down, so I'm going to dig the six post holes... how deep? 16"? 18"? 24"?

I'll concrete them in, and post hole diggers dig what... a 6" diameter hole? I might shave them out to 8" or 10" diameter, but I don't know if that's really necessary if they are the right depth.

So any pointers are more than welcome.

I'm going to build a little building like this, but I'm not going to use wood throughout as this one pictured was made. I'm using a bunch of 6 gauge angle iron for most everything, but the floor will be wood framed and either planked or sheeted.

The floor will not float as high off the ground as this pictured one does, I want mine to have only 6" or so between the ground and the bottom of the 2x6 and 2x4 floor joist frame. So the floor level will be approx 12" above ground.

Ceiling height at the front will be 7' and 6' at the back, so a 12" total roof elevation/slope.

Two rifle benches on the left and two pistol lanes on the right.

I basically just don't want a big wind during any thunderstorm to take this thing down, so I'm going to dig the six post holes... how deep? 16"? 18"? 24"?

I'll concrete them in, and post hole diggers dig what... a 6" diameter hole? I might shave them out to 8" or 10" diameter, but I don't know if that's really necessary if they are the right depth.

So any pointers are more than welcome.

The devastation I saw caused by the April 2011 Alabama tornadoes

The devastation I saw caused by the April 2011 Alabama tornadoes