Dave Markowitz

Member

Last weekend I used a tool made by Joe Wood ("flintsteel" on The Muzzleloading Forum) to cone the muzzle of my longrifle. This was a common practice in the 18th Century and lets you load the gun without a short starter, since the inside of the muzzle is made into a funnel.

Mr. Wood includes excellent instructions and a template for cutting the wet/dry sandpaper you'll need to use his tool.

My longrifle is a .50 Dixie Gunworks Tennesee Mountain Rifle that was restocked by George Dech as a Pennsylvania rifle.

The tool is a tapered brass mandrel with a bore-sized pilot. You use it with varying grades of wet/dry sandpaper attached with double sided carpet tape to form the cone inside the muzzle. I used three pieces each of 220 and 320 grit, then two pieces of 400 grit for the final polish.

I can now seat a .490 in a dry .020 patch flush with the muzzle using only thumb pressure (I generally shoot .018 patches, lubed of course).

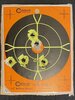

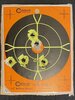

Today I took it to the range for the first time since coning it. As others who've done this report, there was no change to the point of impact or group size. This group was shot offhand at 50 yards with 70 grains of 3Fg black powder, a .490 ball, and .018 ticking lubed with October Country's Bumblin Bear Grease. I used a 6:00 hold.

There's no real need for muzzle coning if you only shoot on the range. However, it's nice to not need a short starter if you are doing a woods walk or hunting.

Mr. Wood includes excellent instructions and a template for cutting the wet/dry sandpaper you'll need to use his tool.

My longrifle is a .50 Dixie Gunworks Tennesee Mountain Rifle that was restocked by George Dech as a Pennsylvania rifle.

The tool is a tapered brass mandrel with a bore-sized pilot. You use it with varying grades of wet/dry sandpaper attached with double sided carpet tape to form the cone inside the muzzle. I used three pieces each of 220 and 320 grit, then two pieces of 400 grit for the final polish.

I can now seat a .490 in a dry .020 patch flush with the muzzle using only thumb pressure (I generally shoot .018 patches, lubed of course).

Today I took it to the range for the first time since coning it. As others who've done this report, there was no change to the point of impact or group size. This group was shot offhand at 50 yards with 70 grains of 3Fg black powder, a .490 ball, and .018 ticking lubed with October Country's Bumblin Bear Grease. I used a 6:00 hold.

There's no real need for muzzle coning if you only shoot on the range. However, it's nice to not need a short starter if you are doing a woods walk or hunting.