mcb

Member

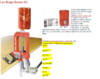

This is a cross section of a Lee FCD, 38/357 in this particular case.

I am assuming the OP removed the upper two parts that actually form the crimp and attempted to push the load 9mm round through the carbide sizing ring at the bottom of the die and it got stuck. From the OP picture is appears the rim is approaching half way through the carbide ring. I would ask what press the OP is using? Some presses are going to give you more mechanical advantage than others. This seem like the OP simply needs a stronger press and a pusher that does not press on the primer like @vaalpens shared and drive that round the rest of the way through. I would spray some good penetrating lubricant in the top of the die and let it sit for awhile to help lubricated it. Again unless I am missing something this simply seems like a modest amount more force is all that is need.

<tongue only partially in my cheek> For that matter point the die in a safe direct and fire it. Put it in a vice with something to protect the threads, point it in a safe direction, Put on some heavy welding gloves, and a good pair of safety glasses and full face shield and use a small diameter punch and hammer and detonate that cartridge. The case is almost through the carbide ring and when the primer and powder go off the top of the case is going to rupture into the oversize ID of the FCD body. The powder will burn very poorly and generate very little pressure and bullet will have relatively low velocity sort of like shooting 9mm in a 40S&W. Then you should be able to hammer that case out or if you like drill out the stuck case to an ID as close as you can get but not touching the carbide and then you should be able to easily pick the remainder of the case out of the die. This last part would be easy on a lathe (as someone mentioned up thread) but prefectly do able with a vice and a pistol drill if you handy. </tongue only partially in my cheek>

I think several of us could come up with a few other ways to clear this with varying levels of risk and tool requirements. Just does not seem that hard of a problem to this engineer. Good luck OP.

I am assuming the OP removed the upper two parts that actually form the crimp and attempted to push the load 9mm round through the carbide sizing ring at the bottom of the die and it got stuck. From the OP picture is appears the rim is approaching half way through the carbide ring. I would ask what press the OP is using? Some presses are going to give you more mechanical advantage than others. This seem like the OP simply needs a stronger press and a pusher that does not press on the primer like @vaalpens shared and drive that round the rest of the way through. I would spray some good penetrating lubricant in the top of the die and let it sit for awhile to help lubricated it. Again unless I am missing something this simply seems like a modest amount more force is all that is need.

<tongue only partially in my cheek> For that matter point the die in a safe direct and fire it. Put it in a vice with something to protect the threads, point it in a safe direction, Put on some heavy welding gloves, and a good pair of safety glasses and full face shield and use a small diameter punch and hammer and detonate that cartridge. The case is almost through the carbide ring and when the primer and powder go off the top of the case is going to rupture into the oversize ID of the FCD body. The powder will burn very poorly and generate very little pressure and bullet will have relatively low velocity sort of like shooting 9mm in a 40S&W. Then you should be able to hammer that case out or if you like drill out the stuck case to an ID as close as you can get but not touching the carbide and then you should be able to easily pick the remainder of the case out of the die. This last part would be easy on a lathe (as someone mentioned up thread) but prefectly do able with a vice and a pistol drill if you handy. </tongue only partially in my cheek>

I think several of us could come up with a few other ways to clear this with varying levels of risk and tool requirements. Just does not seem that hard of a problem to this engineer. Good luck OP.