Badger Arms

Member

I have an FN Trombone rifle that I recently acquired. The firing pin is pretty beat up on it and looks like it might have been either fabricated as a replacement or poorly repaired. From reading the internet, it seems pretty common that these break, but replacements are $50 or more if you can find them. It's a super-simple design and I can make one in about half an hour, but I don't know what kind of material to use.

So, the question is, what type of material should I use and what type of heat treating would be recommended? I need something I can heat treat at home, preferably. The fabrication isn't a big deal. I plan on making it from 1/8" plate stock of whatever I end up getting. I haven't test fired the gun, but I want a replacement firing pin no matter what way I go.

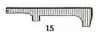

It's a flat steel part, like the Ruger 10/22 one, but thicker. Here's a picture from the IPB:

So, the question is, what type of material should I use and what type of heat treating would be recommended? I need something I can heat treat at home, preferably. The fabrication isn't a big deal. I plan on making it from 1/8" plate stock of whatever I end up getting. I haven't test fired the gun, but I want a replacement firing pin no matter what way I go.

It's a flat steel part, like the Ruger 10/22 one, but thicker. Here's a picture from the IPB: