I do not let epoxy touch anything but the stock and the pillar.

My response was not directed to you, so please do not assume it was. My response was directed to the OP.

I personally do not "pillar only" bed any rifle (with the exception of the Savage B-mag) - and I have blocked and bedded a couple hundred rifles for myself and for others in the last 20yrs working for different gunsmiths. Lots of methods work to improve accuracy; bedding only, blocking only, actions resting on pillars, not resting on pillars... What I use has proven to me it offers the most improvement in accuracy with the greatest longevity (short of gluing the action into the stock), and was passed down to me from rifle builders far above my grade (or appropriately, far above a level far above my grade).

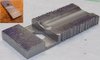

I've improved my process over the years, but have come to see the best potential from a method I was given by Boyd Allen a few years ago, which he was given by George Kelby reportedly many years ago, which also effectively matches instruction from Richard Franklin (he uses flat top pillars even on round actions to let the epoxy create the profile. The pillars are bedded into the stock with screws centered/floating, then the action is bedded with a skim of epoxy over the top of the pillars to eliminate the metal-to-metal contact. This prevents the pillars from creating pressure points as the bedding material shrinks.

Do you know how to test whether your bedding job was a success?

No, I don't. But it's too late now! If you do, you could tell me. I won't recoil in shock.

As another engineer and gunbuilder myself, the tuning fork method is pseudo-science at best, and really doesn't tell you ANYTHING about the efficacy of your bedding job - only about resonance of the barreled action, or rather your subjective thought about how something sounds. The point of a bedding job is to produce a consistent, invariable platform of contact and pressure between the action and the stock - this physical relationship is easily measured with real analytical equipment, not subjective and variable human hearing and observation. Anyone can buy a dial indicator with mag base for $50, not everyone wants to drop hundreds if not thousands of dollars on acoustical testing equipment and software - and again - acoustical testing only gives you the resonance properties of the barreled action over the stock, not about the consistency of the bedding pressure from one shot to the next.

To measure your bedding job:

1) Mount the rifle in a support with the barrel horizontal

2) Mount a magnetic base dial indicator to your barrel, indicating off of the front of the stock

3) Loosen the rear action screw and watch the indicator, if no movement, retension the screw and repeat for the front action screw - feel free to give the muzzle a rap with a rubber or plastic mallet here to see if it gains any movement at all after you've "unseated" it.

4) Repeat with the rifle mounted with the barrel vertical

Any movement on the indicator is the give away the bedding job isn't proper.

If your bedding isn't well fit, the action will rock as the screw tension is released. If the bedding job isn't good: In step 3, you'll see movement as the rear screw is released, as the weight of the barrel will be pushing down, levering the rear screw upward. In step 4, you'll see movement as the front screw is released, as the weight of the barrel will be pulling the action out of the stock (upward relative to the boreline if it were horizontal). Typically have to be really bad before the front screw causes movement in the horizontal test or rear in the vertical.