Wolfman1119

Member

If interested and processing read article if not read below attached note

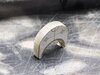

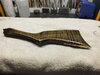

It's looking amazing and I just can't get over how enviously I have no Machinery but people plan on getting me some for my birthday drill press and all that but I have some development and my 499b that I'm converting. It seems like Daisy had to go and make the chamber slightly different than a large chamber as I have gone to the point of deconstructing and reconstructing both the plunger and abutment sides of it with my own macgyvered fashion cuz we all know that I can't stand muzzleloads I'm a repeater guy and I wanted a good seal nonetheless so I got to this point. Also Daisy Infinite Wisdom of triggers couldn't have just stayed with the standard mechanism like all the other wide frames are they had to do a double screw with a slide in and out safety which Beyond me is stupid nothing but a problem the entire time but we're going through and trying to get this right cuz it just seemed to not seal with the previously this was my best option I could think of doing immediately without cutting my own stuff and I have no as I said tools like my kilometers and I can't check sizes past a tape measure or ruler can't wait to see what you got out of that Terry and I tested some oh my guns on a chronograph and I got numbers but I tested a stock Daisy and the thing was saying 250 do they really false advertise at 350 maximum FPS on their boxes and it's only like 250 because then I'll keep my guns down and high 300s if what I'm figuring is correct that my machine's off by 100 ft for some odd reason because I tested two sock red Riders I consecutively found it was within five FPS of 250. I don't know if the corona is right or if my process elimination is right on that cuz if so my model 94 is about 470 FPS average given the fact of the machine I think is $100 off if not it's only at 370 and I'm very depressed about it because it is traveling hot when compared to a standard Daisy I've gone on some of my Vintage Air tubes that I'm using and double ported them as in drilling through the other side evenly and then taking a small file and carefully making sure they're even and that the whole that there goes into is far back on the plunge as I can cuz some of them do not drive with modern plungers they are above the seal and can't have that need as much air possible to be utilized and of course seal as much as possible as Terry and you guys go over. My seals actually a 4-Piece seal from a deconstructed abutment of the 499b but it's fun I feel accomplished when I have to really make stuff from scratch personally Beyond stocks and stuff like that I've made a stock or and like one foregrip which they seem to be a pain to do without a router literally using wood chisels and screwdrivers to have sharpened to do the exact same design as a chisel and yeah I've got my hand a few times over the process price of learning

Edited. It was an epic fail maybe barely travels 5 ft before touching ground it was worse than it was before extremely aggravated with myself is what it is not upset about seal failure upset about trigger mechanism that free floating spring inside of it is a senseless oversight and it's like they designed it to fall apart cuz even the safety Locker pivot point on the front of the trigger mechanism the pen will just slide out if you're too far to the right it was a bad design in general and I'm going to drill out the center marker of an old style trigger to make it work in one of these I will not deal anymore with a double screw trigger design it ain't a safety that aggravates me they should have designed it better

It's looking amazing and I just can't get over how enviously I have no Machinery but people plan on getting me some for my birthday drill press and all that but I have some development and my 499b that I'm converting. It seems like Daisy had to go and make the chamber slightly different than a large chamber as I have gone to the point of deconstructing and reconstructing both the plunger and abutment sides of it with my own macgyvered fashion cuz we all know that I can't stand muzzleloads I'm a repeater guy and I wanted a good seal nonetheless so I got to this point. Also Daisy Infinite Wisdom of triggers couldn't have just stayed with the standard mechanism like all the other wide frames are they had to do a double screw with a slide in and out safety which Beyond me is stupid nothing but a problem the entire time but we're going through and trying to get this right cuz it just seemed to not seal with the previously this was my best option I could think of doing immediately without cutting my own stuff and I have no as I said tools like my kilometers and I can't check sizes past a tape measure or ruler can't wait to see what you got out of that Terry and I tested some oh my guns on a chronograph and I got numbers but I tested a stock Daisy and the thing was saying 250 do they really false advertise at 350 maximum FPS on their boxes and it's only like 250 because then I'll keep my guns down and high 300s if what I'm figuring is correct that my machine's off by 100 ft for some odd reason because I tested two sock red Riders I consecutively found it was within five FPS of 250. I don't know if the corona is right or if my process elimination is right on that cuz if so my model 94 is about 470 FPS average given the fact of the machine I think is $100 off if not it's only at 370 and I'm very depressed about it because it is traveling hot when compared to a standard Daisy I've gone on some of my Vintage Air tubes that I'm using and double ported them as in drilling through the other side evenly and then taking a small file and carefully making sure they're even and that the whole that there goes into is far back on the plunge as I can cuz some of them do not drive with modern plungers they are above the seal and can't have that need as much air possible to be utilized and of course seal as much as possible as Terry and you guys go over. My seals actually a 4-Piece seal from a deconstructed abutment of the 499b but it's fun I feel accomplished when I have to really make stuff from scratch personally Beyond stocks and stuff like that I've made a stock or and like one foregrip which they seem to be a pain to do without a router literally using wood chisels and screwdrivers to have sharpened to do the exact same design as a chisel and yeah I've got my hand a few times over the process price of learning

Edited. It was an epic fail maybe barely travels 5 ft before touching ground it was worse than it was before extremely aggravated with myself is what it is not upset about seal failure upset about trigger mechanism that free floating spring inside of it is a senseless oversight and it's like they designed it to fall apart cuz even the safety Locker pivot point on the front of the trigger mechanism the pen will just slide out if you're too far to the right it was a bad design in general and I'm going to drill out the center marker of an old style trigger to make it work in one of these I will not deal anymore with a double screw trigger design it ain't a safety that aggravates me they should have designed it better

Attachments

Last edited: