I have a model 1903 that I have owned for a couple months. When I tilt the gun back and forwards, I hear a rattling or something rolling around in the stock of my rifle. I want to go shooting but I am afraid it is something serious and the rifle may blow up in my face. The wood does not look original. It is a rock island model 1903

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

-

Not open for further replies.

AlexanderA

Member

The obvious answer is that the oiler could be sliding back and forth in the butt trap. A couple of folded cleaning patches placed behind the oiler will prevent this.

Another possibility for a rattle is the ejector. It's pinned (pivoted) on the inside of the receiver, at the rear left side, just in front of the magazine cutoff. By design, it's a loose fit, and swings easily. There's a remote chance that that's what you're hearing.

Another possibility for a rattle is the ejector. It's pinned (pivoted) on the inside of the receiver, at the rear left side, just in front of the magazine cutoff. By design, it's a loose fit, and swings easily. There's a remote chance that that's what you're hearing.

tark

Member

Is it a low number gun? under 285,507 or there about. The first 03s made used a single heat treat for the receiver. There were problems, as in they could shatter upon firing. The number that did was a tiny fraction of one percent, but it did kill some people. Some people refuse to shoot them, I shoot mine all the time....with reduced loads. You must remember the "low number" guns had to pass proof at 70,000 PSI, and we went through WW I with low numbered guns, where the gun achieved its legendary status. If your gun is a low number gun it's up to you whether or not to use factory ammo but if it shows a lot of obvious wear, well, its probably had a lot of rounds put through it already. My 03 was proved at the Arsenal, sent off to war, and rebuilt at the San Antonio Arsenal during WW II. It was re-barreled there and proved again with another 70,000 PSI pill!! So here is a low numbered gun that was proved TWICE and survived just fine.

If your gun is above 285507 you have nothing to ponder about. Enjoy

Almost forgot....Welcome to the monkey house

If your gun is above 285507 you have nothing to ponder about. Enjoy

Almost forgot....Welcome to the monkey house

The serial number is 223936Is it a low number gun? under 285,507 or there about. The first 03s made used a single heat treat for the receiver. There were problems, as in they could shatter upon firing. The number that did was a tiny fraction of one percent, but it did kill some people. Some people refuse to shoot them, I shoot mine all the time....with reduced loads. You must remember the "low number" guns had to pass proof at 70,000 PSI, and we went through WW I with low numbered guns, where the gun achieved its legendary status. If your gun is a low number gun it's up to you whether or not to use factory ammo but if it shows a lot of obvious wear, well, its probably had a lot of rounds put through it already. My 03 was proved at the Arsenal, sent off to war, and rebuilt at the San Antonio Arsenal during WW II. It was re-barreled there and proved again with another 70,000 PSI pill!! So here is a low numbered gun that was proved TWICE and survived just fine.

If your gun is above 285507 you have nothing to ponder about. Enjoy

Almost forgot....Welcome to the monkey house

The serial number is 223936Is it a low number gun? under 285,507 or there about. The first 03s made used a single heat treat for the receiver. There were problems, as in they could shatter upon firing. The number that did was a tiny fraction of one percent, but it did kill some people. Some people refuse to shoot them, I shoot mine all the time....with reduced loads. You must remember the "low number" guns had to pass proof at 70,000 PSI, and we went through WW I with low numbered guns, where the gun achieved its legendary status. If your gun is a low number gun it's up to you whether or not to use factory ammo but if it shows a lot of obvious wear, well, its probably had a lot of rounds put through it already. My 03 was proved at the Arsenal, sent off to war, and rebuilt at the San Antonio Arsenal during WW II. It was re-barreled there and proved again with another 70,000 PSI pill!! So here is a low numbered gun that was proved TWICE and survived just fine.

If your gun is above 285507 you have nothing to ponder about. Enjoy

Almost forgot....Welcome to the monkey house

Like I said in the thread, the wood is not original, it doesn't look like a 1903 at all. The closest thing it looks like is the model 1903 nra variantWhat Ilbob suggested. Check the buttstock compartment.

The wood is not original, the closest thing it looks like is the model 1903 nra variant.What Ilbob suggested. Check the buttstock compartment.

Is it a low number gun? under 285,507 or there about. The first 03s made used a single heat treat for the receiver. There were problems, as in they could shatter upon firing. The number that did was a tiny fraction of one percent, but it did kill some people. Some people refuse to shoot them, I shoot mine all the time....with reduced loads. You must remember the "low number" guns had to pass proof at 70,000 PSI, and we went through WW I with low numbered guns, where the gun achieved its legendary status. If your gun is a low number gun it's up to you whether or not to use factory ammo but if it shows a lot of obvious wear, well, its probably had a lot of rounds put through it already. My 03 was proved at the Arsenal, sent off to war, and rebuilt at the San Antonio Arsenal during WW II. It was re-barreled there and proved again with another 70,000 PSI pill!! So here is a low numbered gun that was proved TWICE and survived just fine.

If your gun is above 285507 you have nothing to ponder about. Enjoy

Almost forgot....Welcome to the monkey house

Went back and checked my copy of Hatcher, the low numbers begin at 800,000 for a 1903 made at Springfield Armory and 285507 for those made at Rock Island Armory (source CMP http://thecmp.org/cmp_sales/rifle_sales/m1903-m1903a3/).

O/P, you will find some additional good information about the 1903 from this website including manufacturing dates http://m1903.com/

tark

Member

A pic would go a long way in determining exactly what you have. The N.R.A. sporters are quite valuable.The serial number is 223936

Sunray

Member

The receiver was made in 1913. It's a low S/N that sounds like it was "sporterised" and isn't considered safe to shoot with any ammo. It's one of those things that might happen at any time vs will happen. Buy a copy of Hatcher's Notebook for a full explanation of the 1903 S/N issue. $25.40US on Amazon and worth every cent.

However, as mentioned, there's likely something in the hole under the butt plate. Take it off and whatever it is will come out. Whatever it is will not cause the thing to explode.

However, as mentioned, there's likely something in the hole under the butt plate. Take it off and whatever it is will come out. Whatever it is will not cause the thing to explode.

Clark

Member

My father got a marksmanship badge in 1944 with a Springfield when he entered WWII as a second lieutenant. When he got out of the Army 2 years later, he bought a made in1931 Springfield from Sears and Roebuck for $39.95 from his $20/week unemployment compensation. More recently my brother shot a bear with it.

The more I study this issue, the more I am disturbed to read the narratives from people whom the shooting community considers to an authority figure. Dr Lyon’s is one, he is a low number Springfield fan and by his analysis published at M1903.com he is promoting risky behavior.

http://m1903.com/03rcvrfail/

Some Observations On The Failure Of U.S. Model 1903 Rifle Receivers

Dr Lyon’s risk analysis is solely based on the list in Hatcher’s Notebook. There are known low number blowups before Hatcher’s list starts, and there are known low number blowups after Hatcher’s database ends. Hatcher’s list is an incomplete list of low number accidents. It is really disturbing to realize that Dr Lyon is a medical Doctor and to see that his analysis ignores underlying causes. No wonder 120,000 people die each year to medical mistakes. Dr Lyon’s is not interested why these things break. His analysis is strictly on the numbers in a data base. For him, the characteristics of low number receivers are irrelevant. The technology of the era, the poor quality of the steel, the lack of process control technology, these are all ignored by Dr Lyon. It is as if low number failures have no assignable causes: the receivers just blow up randomly. No rime or reason to it, just acts of God, totally unknowable and unforeseeable. His statistics provide assurance to many that the risk of shooting a low number receiver is very small, but his analysis is very flawed . There are reasons beyond random chance why these receivers are structurally deficient.

Early 03 failures

http://castboolits.gunloads.com/showthread.php?34480-quot-brittle-quot-receivers/page2

There are a number of issues with all of the single heat treat 03's. Firstly, the problem was not the heat treatment. The single heat treatment would have produced a perfectly satisfactory receiver, (caveat: for the period) but Army was negligent in buying instrumentation for their factories. Instead of buying pyrometers, workers were required to judge steel temperature based on their eyeballs. Eyeballs cannot hold the temperature tolerances required for heat treatment of those steels. Basically the workers were using Medieval production methods because it was cheaper, and the Army priorities were not keeping their Arsenals up to date. I am of the opinion it was more than benign neglect, it was a matter of Corporate Culture. According Dr Deiter Storz's book: Rifle & Carbine 98: M98 Firearms of the German Army from 1898 to 1918 Amberg Arsenal installed pyrometers in 1906. The German Technical staff and Managers recognized the limitations of eyeballs in heat treatment, that is they thought about it, and decided to improve their production line to make good rifles.

As an example of the improvement in duty lifetime when production lines were organized logically, and instrument used to evaluate temperature, instead of eyeballs, I offer this is book review from Jan 1926 Transactions of the American Society for Steel Treating.

Making Springs for Motor Vehicles

Canadian Machinery, 12 Nov 1925, page 15

The author of this paper discusses the benefits that have come to the manufacture of springs in the motor car industry from metallurgical research. Springs today stand four or five times the work of those a few year ago because the “skill” and “guessing” of the forger has been replaced by heat treating furnaces with temperatures maintained at the proper degree by pyrometers. The Dowsley Spring and Axle Co., Chatham, Ont., a subsidiary of the Ontario Products Co., is taken as an example of a thoroughly modern plant, and its work discussed. There are 145 men employed in the plant and production averages about 55 tons of springs a day, a single spring weighing anywhere from 17 to 44 pounds.

The plant is so arranged that material follows a straight path from storage to shipping room. Until a few years ago all springs were heat treated in small oil-fired furnaces. Today this method had been discarded. A continuous heat treating, forming, and quenching process has been evolved, which is practically automatic and eliminates the human element. As an example of what careful- heat treatment has done toward prolonging the life of springs, the results of test of springs made by the hand method and those by the continuous heat treatment method are interesting. Some years ago 40,0000 deflections were about the average before failure, now 120,000 is a low figure.

You can see in this the early vacuum tube era (1925) that a changeover from eyeballs to temperature gauges has really improved the fatigue lifetime of springs.

If the receiver was burnt, that is over heated during forging, it cannot be fixed by heat treating. Burning steel is not like burning toast but anyone with brains has noticed you cannot stick burnt toast back in the toaster and heat it back to fresh. Once ruined, it is ruined. Burnt steel is a fusion reaction, fusing the steel into one big austenite crystal. The desired crystalline structure is martensitic. But when steel is raised to a “white hot” temperature the steel is all in the austineitic phase. When it cools from this temperature it is a very hard, brittle steel. I have been told by metallurgists the carbon is burnt out. It is impossible to anneal or heat treat burnt steel back to a useable material. Long anneals will break up some of the hard areas, but not all. To make the steel useable it would have to be completed melted and cast again, as it is came from the steel foundry.

The single heat treat cycle was

Receivers and bolts of SA, serial number 1 to 800,000

Material, Class C Steel

Treatment: Carburize in bone at 1500 F for 4 hours, then quench in oil

Another problem with single and double heat treat receivers is the low grade of the Class C and Class A materials used in single and double heat treat receivers. These materials are low strength and have a very low fatigue life compared to alloy steels. In every particular, these plain carbon steels are inferior to alloy steels. Watertown Arsenal was urging Springfield Armory to use 2340 instead of Class C steels prior to WW1, and the recommendations were ignored. Springfield Armory used this stuff primarily because it was cheap and the production engineers at Springfield Armory were familiar with the material. There is no justification for the continued use of these materials based on material properties. Today identical materials are used on rail road spikes and cheap rebar, because they are so low grade and cheap. No one in their right mind would use the same materials in a firearms application, unless they wanted to be sued. Plain carbon steels were commonly used on parts prior to WW2, but metallurgy in the 1920's and 30's advanced so quickly that by the time you get to WW2 it is obvious that plain carbon steels are only a good choice if cost is the number one criteria and the loads are not high or safety critical.

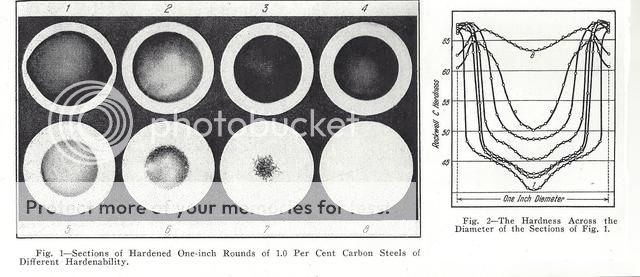

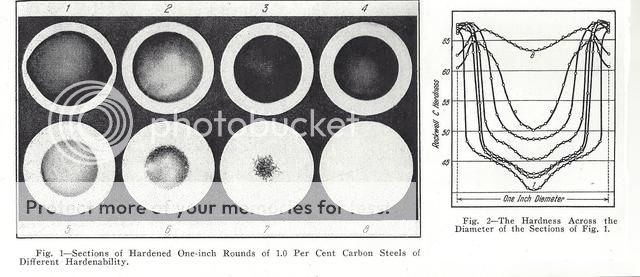

The American metallurgist Edgar Bain, http://www.nasonline.org/publications/biographical-memoirs/memoir-pdfs/bain-edgar-c.pdf in 1932 published conclusive experiments on carbons steels. Bain heat treated identical plain carbon steel coupons under identical conditions and examined the coupons afterwards for hardness depth. The black chemical etching, which I assume is the unhardened steel, show that plain carbon steels have erratic hardening depths, given that all else is equal. These steels were called in WW2 era text books as “shallow hardening”. This was meant not as praise but as a pejorative. As is shown on the right of the diagram, the hardness of these coupons varies by depth. This is not good as consistent hardening provides consistent material properties. It is undesirable to create parts some of which will be hard through and through but others soft below the surface even though the heating processes are the same for all parts. But use plain carbon steels, and you will create such inconsistent parts, just by the nature of the material.

Therefore, you would expect even properly forged, properly heat treated single heat treat and double heat treat receivers to vary considerable in hardness depth, which then affects the properties of the end part.

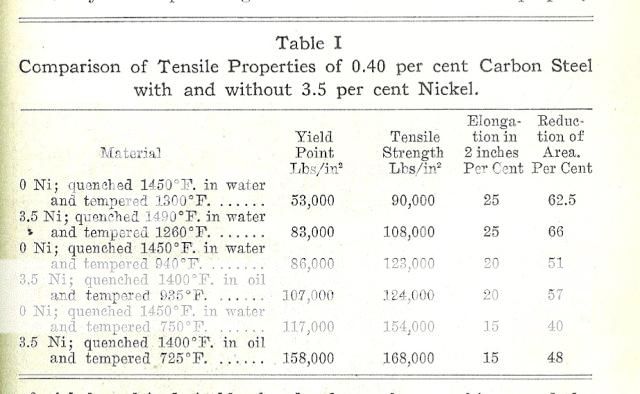

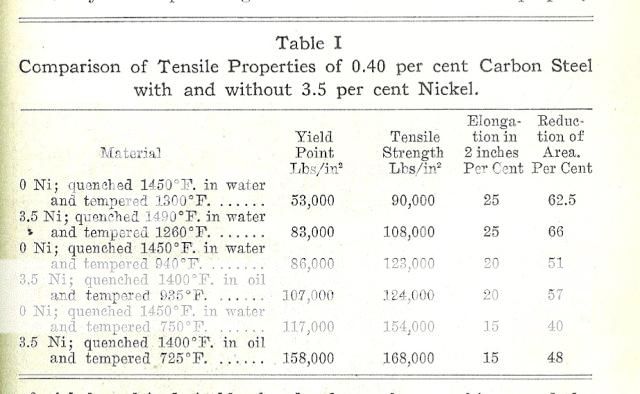

Yield is an extremely important material property, for above yield, the part deforms. Once a steel part yields it is no longer safe to use. What happens after yield is unpredictable, often it takes less load to cause more deformation, ultimate load is the load it takes to break the part. In this early 1920’s chart, for the same essential heat treatment, the nickel alloy steel always has a higher yield, a significantly higher yield in all cases, than the plain carbon steel.

Nickel steel versus plain carbon steel

What is not shown in these charts is a material property called toughness. For a device, such as a receiver, which is going to be subjected to impact loading, toughness is a highly desirable property. Toughness is directly related to fatigue lifetime, which is the number of loading cycles to failure. Assuming the yield is sufficient for the load, the tougher material will have a longer service life. Alloy steels have a greater toughness than plain carbon steels. Alloy steels take more energy to shear, Charpy impact tests are a direct predictor of a steel’s fatigue lifetime. It is a revelation to see just how shear energy decreases with temperature, and at low temperature, alloy steels take several times the energy to shear as do plain carbon steels.

Pryometric cones have been around since the 1800’s, but I have no idea if they were used at Springfield Arsenal or even in the steel mills of the period. I don’t know if anyone reading this understands vacuum tube technology, late vacuum tube technology was much better than early vacuum tube technology, and no vacuum tube technology meant process controls depended on sight, taste, touch, and smell. These early M1903’s are pre vacuum tube technology. Human sensory perceptions have their limits and processes governed by them are not going to be very exact or repeatable. You see this in every evaluation of the steels of the period. This is an excellent example of what I find when someone reports a technical analysis of WW1 era steels:

Rolling Block strenght

http://castboolits.gunloads.com/showthread.php?52526-Rolling-Block-strenght/page2

Therefore, old single heat treat receivers are a very significant unknown quantity. We know they were made in a factory that did not have temperature controls, we know that the material varies considerably in properties after heat treatment, and that the service life of the part will always be less to one made out of a good alloy steel. We also know the steels of the period were inferior in material properties to the exact same compositions made today, just due to the process controls of the period. Just how many service lives have these old receivers been though? How many more load cycles will they take before failure? How will they react in an overpressure situation?

Therefore, regardless of the feeling around vintage weapons or “old world craftsmanship”, or the romantic feelings and emotions of those who believe the past was a better place, these old plain carbon steels are inferior in all aspects to alloy steels. It is my opinion that a combination of false economy and just reluctance to change by the Chief Metallurgist is why Springfield Armory kept using plain carbon steels even when early in the 20th century, it was obvious that these steels were rapidly becoming obsolescent, and by the 1920’s, they were obsolete for this application.

So, based on the unpredictability of these low number receivers, you just don't know how long it will be till something breaks. There were so many accidents that in 1927 an Army board looked at these things, reheated samples and found that 33 1/3% would break in an overpressure condition. The board recommended scrapping all 1,000,000 of the rifles, but because it was the cheaper solution, the Army decided to keep the rifles in service. It was cheaper to injure a Soldier, Sailor, or Marine than to replace the $40.00 rifle that injured the man. I don't know your feeling about this, but I consider this evil and unethical behavior. Any service man refusing to shoot this rifle, because of fears it might break, would be subject to a court marshal, but this is a moot point: they were not informed anyway. The Army never really went out and told anyone that their rifles were defective, we did not know the true extent of the problem until the Springfields were out of service, and Hatcher published his Book: Hatcher's Notebook in 1947!

In 1947, in his book Hatcher’s Notebook, Hatcher weaves a story that blames the lack of temperature gages on the forge shop workers. You know, those forge shop workers who were suspicious of new technology. Hatcher spins a tale where considerate Army management soothes the nervousness of those workers by not buying the latest technology. I am so certain that many readers of this post found their management so accommodating, so considerate of their feelings, that they were consulted well before they were replaced with a robot.

I also invite all readers to watch an interesting program : Forged in Fire. I like sharp pointy knives and this program has knife makers forging knives under unreasonably short time constraints. The first elimination stage, the makers have to forge a blade that passes inspection. Frequently, very frequently, these experienced knife makers over heat their blades and the things show up cracked. It looks like they are heating the things by eye and due to time constraints, many blanks are overheated. Knives that were not obviously cracked at first inspection, have shattered in chopping tests. Early in the program they tested blades with cracks, now the judges flat out refuse to test any blade showing cracks. Recently I saw an episode where the criticality of quench media was proven. The knife maker firstly quenched his blade in oil, and to speed up the cooling to ambient, he did a finish quench in water. That water quench cracked his blade. He was eliminated. Each knife maker gets a short autobiography at the beginning of the show, so these guys have years, some decades of experience. From what I have seen, it is easy to over heat steel and damage it during quench. Considering the instrumentation in the forge shops of Springfield Armory and Rock Island Armory was human eyeballs, it is reasonable to assume that any part heated in these Arsenals would have similar issues to those knives forged and quenched during this program.

There are other sources that through Google books that have recently come available, and they provide enough information to confound the Hatcher morality tale that the low number rifle problem receiver problem was due to a few bad apples in the forge shop.

Report of Tests of Metals and Other Materials made in Ordinance Laboratory at Watertown Arsenal Mass, Fiscal Year 1918, War Department Document 901, 338 pp.

https://books.google.com/books/read...printsec=frontcover&output=reader&pg=GBS.PA25

I have copied a few of the Watertown summaries. Some maybe duplicative of those in Hatcher’s Notebook, I invite posters to point out the duplicates.

Examination of Receivers from United States Rifles Model of 1903, burst during Navy Target Practice

Conclusions:

One of the receivers was neither case hardened nor heat treated. It was in the perlitic condition as shown by the micrographs. The structure was very coarse.

Examination of United States Rifle, Caliber 30, Model of 1903, which failed at Camp Greene NC

Conclusions.

The receiver of this rifle had not been properly heat treated prior to being put in service. Microscopic examination showed the metal to be very coarsely crystalline and the structure was that obtained by cooling at a fairly rapid rate from a high temperature. The metal was very brittle under impact, as evidenced by its being readily broken when struck a light blow with a hammer.

Broken Bolts from United States Rifle, Caliber 0.30 Model of 1903

Object: The object of this investigation was to make a complete examination of these two bolts and if possible determine the cause of failure.

Conclusions: It is the conclusion of this laboratory that the failure of both of these bolts is due to the same factor. Both were very hard and brittle and their resistance to sudden impact was very low, as could be ascertained by securely fastening the metal in a vise and striking light blows with a hammer. the brinell hardess number on one of these was 430 and on the other it was 489. these structure of both was martensitic. This structure is characteristic of very brittle material

The chemical composition of these bolts is not within the specified limits with regard to carbon, manganese, and silicon

Investigation of cause of failure of United States rifle Model of 1903, No 108 448, which failed in target practice at Camp Shelby

Conclusions:

It is the conclusion of the laboratory that the failure of this rifle was due, at least partially, if not entirely to defective material composing the barrel. Chemical analysis shows the phosphorus to be 0.083, which is entirely too high and should not be allowed. The metal is very severely banded or streaked longitudinally, as shown by etching polished sections with Stead's reagent. Nonmetallic inclusions were present in considerable quantity and were greatly elongated in the longitudinal direction of the barrel.

The weakening effect of these streaks, rich in phosphorus and containing a large amount of nonmetallic inclusions is particularly apparent under shock. The brittleness under sudden impact caused by high phosphorus and nonmetallic inclusions, especially when in the banded condition, is without doubt the predominating factor contributing directly to the failure of this rifle. The metal of the receiver was very hard and brittle, as can be at once understood by observing micrograph 4215 at 500 diameters , which shows the structure to be martensitic.

A couple of issues fall out, and they are not as simple as a morality play between virtuous Army Ordnance Officer's and villainous forge shop workers. Firstly, the materials they are using are inconsistent and don't meet specifications. . They don't have an incoming material inspection nor a material certification of incoming materials. I know from historical sources that the materials of the age were widely inconsistent, and the chemical analyses by Watertown shows that. These are plain carbon steels with slag, inclusions, high amounts of Phosphors or Sulfur, and all of these defects weaken the end product. I remember Colt had a metallurgical department that performed chemical analysis of the steels from Colt vendors. These Arsenals don’t order steel in 10 pound, 20 pound lots, they order steel in lots of 100,000 pounds or more. We are talking about costs in the $250,000 dollars per order. Why did not Springfield Armory require a chemical test as part of the purchase order or do it in house? Heat treatment temperatures are based on the percentage of carbon in the steel and the heat treatment is specific to the carbon content. Improper carbon content results in a improper heat treatment, and the end result is a part with improper material properties for the application. Like too hard, too soft.

And, rifles are being proofed and shipped out that don’t have heat treated receivers! That shows an out of control production line. This in itself is a huge topic, how to get a production line that produces good product, not a mix of good, bad, sort of good but not too bad product. The Army’s factories were mismanaged and behind the times, even for WW1 factory. No wonder that one third of the rifles produced were structurally deficient.

As to shooting one of these rifles, understand that they are old, have an unknown number of rounds through them. Whatever fatigue life was in the things when they were new, has been used up through the years. If the receiver or bolt fails, the M1903 action has virtually no shooter protection features. Gas will go down the firing pin shaft directly into your eyes. Escaping gas is not funneled or controlled, like the breech of a M700 Remington, often the receiver ring is blown off. There will be chunks and pieces of metal flying around and at someone died once.

Low number 03 failure

https://www.facebook.com/groups/1903loverscollectors/

"13 grains of unique 200 grain lead bullet cci 200 primers. This is the case I beat out of the chamber"

"The bolt looks to be undamaged. Took a block and a hammer to get Open and a 1/4 steelrod to get the case out"

"My son is a safe reloaded and has not had any problems with the many hundreds he has loaded"

"The sad part or good part he had just fired 35 full power loads"

"It was a 14 grains of unique with a 311284 bullet cast with lyman #2 alloy and gas checked"

This one came with a lot of pictures:

http://www.gunbroker.com/Auction/ViewItem.aspx?Item=190985391

[/URL

[/URL

]

[/URL

[/URL

]

[/URL

[/URL

]

[/URL

[/URL

]

[/URL

[/URL

]

[/URL

[/URL

]

[/URL

[/URL

]

[/URL

[/URL

]

[/URL

[/URL

]

[/URL

[/URL

]

[/URL

[/URL

]

[/URL

[/URL

]

http://m1903.com/03rcvrfail/

Some Observations On The Failure Of U.S. Model 1903 Rifle Receivers

Dr Lyon’s risk analysis is solely based on the list in Hatcher’s Notebook. There are known low number blowups before Hatcher’s list starts, and there are known low number blowups after Hatcher’s database ends. Hatcher’s list is an incomplete list of low number accidents. It is really disturbing to realize that Dr Lyon is a medical Doctor and to see that his analysis ignores underlying causes. No wonder 120,000 people die each year to medical mistakes. Dr Lyon’s is not interested why these things break. His analysis is strictly on the numbers in a data base. For him, the characteristics of low number receivers are irrelevant. The technology of the era, the poor quality of the steel, the lack of process control technology, these are all ignored by Dr Lyon. It is as if low number failures have no assignable causes: the receivers just blow up randomly. No rime or reason to it, just acts of God, totally unknowable and unforeseeable. His statistics provide assurance to many that the risk of shooting a low number receiver is very small, but his analysis is very flawed . There are reasons beyond random chance why these receivers are structurally deficient.

Early 03 failures

http://castboolits.gunloads.com/showthread.php?34480-quot-brittle-quot-receivers/page2

I once corresponded with a lady, but when I mentioned to her that I belonged to the NRA, she became totally unglued. It seems that her father had been killed by one of the early 03's, the rifle having been purchased surplus through the NRA. She blamed the NRA for her father's death, and repeatedly asked me if the problem had been known before the sale of her father's rifle. I replied that I was not an expert, but that I believed it had been the after-sale deaths that turned up the problem.

So yes, some of them did fail, and take their shooters with them. I believe she said that it had been commercial ammunition, as well.

This being the reason they had known the problem was the rifle itself, not the ammo.

There are a number of issues with all of the single heat treat 03's. Firstly, the problem was not the heat treatment. The single heat treatment would have produced a perfectly satisfactory receiver, (caveat: for the period) but Army was negligent in buying instrumentation for their factories. Instead of buying pyrometers, workers were required to judge steel temperature based on their eyeballs. Eyeballs cannot hold the temperature tolerances required for heat treatment of those steels. Basically the workers were using Medieval production methods because it was cheaper, and the Army priorities were not keeping their Arsenals up to date. I am of the opinion it was more than benign neglect, it was a matter of Corporate Culture. According Dr Deiter Storz's book: Rifle & Carbine 98: M98 Firearms of the German Army from 1898 to 1918 Amberg Arsenal installed pyrometers in 1906. The German Technical staff and Managers recognized the limitations of eyeballs in heat treatment, that is they thought about it, and decided to improve their production line to make good rifles.

As an example of the improvement in duty lifetime when production lines were organized logically, and instrument used to evaluate temperature, instead of eyeballs, I offer this is book review from Jan 1926 Transactions of the American Society for Steel Treating.

Making Springs for Motor Vehicles

Canadian Machinery, 12 Nov 1925, page 15

The author of this paper discusses the benefits that have come to the manufacture of springs in the motor car industry from metallurgical research. Springs today stand four or five times the work of those a few year ago because the “skill” and “guessing” of the forger has been replaced by heat treating furnaces with temperatures maintained at the proper degree by pyrometers. The Dowsley Spring and Axle Co., Chatham, Ont., a subsidiary of the Ontario Products Co., is taken as an example of a thoroughly modern plant, and its work discussed. There are 145 men employed in the plant and production averages about 55 tons of springs a day, a single spring weighing anywhere from 17 to 44 pounds.

The plant is so arranged that material follows a straight path from storage to shipping room. Until a few years ago all springs were heat treated in small oil-fired furnaces. Today this method had been discarded. A continuous heat treating, forming, and quenching process has been evolved, which is practically automatic and eliminates the human element. As an example of what careful- heat treatment has done toward prolonging the life of springs, the results of test of springs made by the hand method and those by the continuous heat treatment method are interesting. Some years ago 40,0000 deflections were about the average before failure, now 120,000 is a low figure.

You can see in this the early vacuum tube era (1925) that a changeover from eyeballs to temperature gauges has really improved the fatigue lifetime of springs.

If the receiver was burnt, that is over heated during forging, it cannot be fixed by heat treating. Burning steel is not like burning toast but anyone with brains has noticed you cannot stick burnt toast back in the toaster and heat it back to fresh. Once ruined, it is ruined. Burnt steel is a fusion reaction, fusing the steel into one big austenite crystal. The desired crystalline structure is martensitic. But when steel is raised to a “white hot” temperature the steel is all in the austineitic phase. When it cools from this temperature it is a very hard, brittle steel. I have been told by metallurgists the carbon is burnt out. It is impossible to anneal or heat treat burnt steel back to a useable material. Long anneals will break up some of the hard areas, but not all. To make the steel useable it would have to be completed melted and cast again, as it is came from the steel foundry.

The single heat treat cycle was

Receivers and bolts of SA, serial number 1 to 800,000

Material, Class C Steel

Treatment: Carburize in bone at 1500 F for 4 hours, then quench in oil

Another problem with single and double heat treat receivers is the low grade of the Class C and Class A materials used in single and double heat treat receivers. These materials are low strength and have a very low fatigue life compared to alloy steels. In every particular, these plain carbon steels are inferior to alloy steels. Watertown Arsenal was urging Springfield Armory to use 2340 instead of Class C steels prior to WW1, and the recommendations were ignored. Springfield Armory used this stuff primarily because it was cheap and the production engineers at Springfield Armory were familiar with the material. There is no justification for the continued use of these materials based on material properties. Today identical materials are used on rail road spikes and cheap rebar, because they are so low grade and cheap. No one in their right mind would use the same materials in a firearms application, unless they wanted to be sued. Plain carbon steels were commonly used on parts prior to WW2, but metallurgy in the 1920's and 30's advanced so quickly that by the time you get to WW2 it is obvious that plain carbon steels are only a good choice if cost is the number one criteria and the loads are not high or safety critical.

The American metallurgist Edgar Bain, http://www.nasonline.org/publications/biographical-memoirs/memoir-pdfs/bain-edgar-c.pdf in 1932 published conclusive experiments on carbons steels. Bain heat treated identical plain carbon steel coupons under identical conditions and examined the coupons afterwards for hardness depth. The black chemical etching, which I assume is the unhardened steel, show that plain carbon steels have erratic hardening depths, given that all else is equal. These steels were called in WW2 era text books as “shallow hardening”. This was meant not as praise but as a pejorative. As is shown on the right of the diagram, the hardness of these coupons varies by depth. This is not good as consistent hardening provides consistent material properties. It is undesirable to create parts some of which will be hard through and through but others soft below the surface even though the heating processes are the same for all parts. But use plain carbon steels, and you will create such inconsistent parts, just by the nature of the material.

Therefore, you would expect even properly forged, properly heat treated single heat treat and double heat treat receivers to vary considerable in hardness depth, which then affects the properties of the end part.

Yield is an extremely important material property, for above yield, the part deforms. Once a steel part yields it is no longer safe to use. What happens after yield is unpredictable, often it takes less load to cause more deformation, ultimate load is the load it takes to break the part. In this early 1920’s chart, for the same essential heat treatment, the nickel alloy steel always has a higher yield, a significantly higher yield in all cases, than the plain carbon steel.

Nickel steel versus plain carbon steel

What is not shown in these charts is a material property called toughness. For a device, such as a receiver, which is going to be subjected to impact loading, toughness is a highly desirable property. Toughness is directly related to fatigue lifetime, which is the number of loading cycles to failure. Assuming the yield is sufficient for the load, the tougher material will have a longer service life. Alloy steels have a greater toughness than plain carbon steels. Alloy steels take more energy to shear, Charpy impact tests are a direct predictor of a steel’s fatigue lifetime. It is a revelation to see just how shear energy decreases with temperature, and at low temperature, alloy steels take several times the energy to shear as do plain carbon steels.

Pryometric cones have been around since the 1800’s, but I have no idea if they were used at Springfield Arsenal or even in the steel mills of the period. I don’t know if anyone reading this understands vacuum tube technology, late vacuum tube technology was much better than early vacuum tube technology, and no vacuum tube technology meant process controls depended on sight, taste, touch, and smell. These early M1903’s are pre vacuum tube technology. Human sensory perceptions have their limits and processes governed by them are not going to be very exact or repeatable. You see this in every evaluation of the steels of the period. This is an excellent example of what I find when someone reports a technical analysis of WW1 era steels:

Rolling Block strenght

http://castboolits.gunloads.com/showthread.php?52526-Rolling-Block-strenght/page2

I did not know this until I looked as a response to your post. However, I have worked with Steel my entire professional career. I was the head of a Testing Lab in a steel manufacturing facility for 4+ years. During that time, I was provided a ferrule from a WW1 fighter airplane for testing. It was made from what was labeled "high strength steel" (the label was from WW1). I tested it and found that it was lower strength than the lowest strength steel that can be bought today. In addition, it had a lot more impurities than would be allowed today, particularly sulfer. (PS. "today" means from about 1975 to 1980). I know that steel has continued to increase since then in strength, ductility, and all the other desireable characteristics we use without thinking about it.

Therefore, old single heat treat receivers are a very significant unknown quantity. We know they were made in a factory that did not have temperature controls, we know that the material varies considerably in properties after heat treatment, and that the service life of the part will always be less to one made out of a good alloy steel. We also know the steels of the period were inferior in material properties to the exact same compositions made today, just due to the process controls of the period. Just how many service lives have these old receivers been though? How many more load cycles will they take before failure? How will they react in an overpressure situation?

Therefore, regardless of the feeling around vintage weapons or “old world craftsmanship”, or the romantic feelings and emotions of those who believe the past was a better place, these old plain carbon steels are inferior in all aspects to alloy steels. It is my opinion that a combination of false economy and just reluctance to change by the Chief Metallurgist is why Springfield Armory kept using plain carbon steels even when early in the 20th century, it was obvious that these steels were rapidly becoming obsolescent, and by the 1920’s, they were obsolete for this application.

So, based on the unpredictability of these low number receivers, you just don't know how long it will be till something breaks. There were so many accidents that in 1927 an Army board looked at these things, reheated samples and found that 33 1/3% would break in an overpressure condition. The board recommended scrapping all 1,000,000 of the rifles, but because it was the cheaper solution, the Army decided to keep the rifles in service. It was cheaper to injure a Soldier, Sailor, or Marine than to replace the $40.00 rifle that injured the man. I don't know your feeling about this, but I consider this evil and unethical behavior. Any service man refusing to shoot this rifle, because of fears it might break, would be subject to a court marshal, but this is a moot point: they were not informed anyway. The Army never really went out and told anyone that their rifles were defective, we did not know the true extent of the problem until the Springfields were out of service, and Hatcher published his Book: Hatcher's Notebook in 1947!

In 1947, in his book Hatcher’s Notebook, Hatcher weaves a story that blames the lack of temperature gages on the forge shop workers. You know, those forge shop workers who were suspicious of new technology. Hatcher spins a tale where considerate Army management soothes the nervousness of those workers by not buying the latest technology. I am so certain that many readers of this post found their management so accommodating, so considerate of their feelings, that they were consulted well before they were replaced with a robot.

I also invite all readers to watch an interesting program : Forged in Fire. I like sharp pointy knives and this program has knife makers forging knives under unreasonably short time constraints. The first elimination stage, the makers have to forge a blade that passes inspection. Frequently, very frequently, these experienced knife makers over heat their blades and the things show up cracked. It looks like they are heating the things by eye and due to time constraints, many blanks are overheated. Knives that were not obviously cracked at first inspection, have shattered in chopping tests. Early in the program they tested blades with cracks, now the judges flat out refuse to test any blade showing cracks. Recently I saw an episode where the criticality of quench media was proven. The knife maker firstly quenched his blade in oil, and to speed up the cooling to ambient, he did a finish quench in water. That water quench cracked his blade. He was eliminated. Each knife maker gets a short autobiography at the beginning of the show, so these guys have years, some decades of experience. From what I have seen, it is easy to over heat steel and damage it during quench. Considering the instrumentation in the forge shops of Springfield Armory and Rock Island Armory was human eyeballs, it is reasonable to assume that any part heated in these Arsenals would have similar issues to those knives forged and quenched during this program.

There are other sources that through Google books that have recently come available, and they provide enough information to confound the Hatcher morality tale that the low number rifle problem receiver problem was due to a few bad apples in the forge shop.

Report of Tests of Metals and Other Materials made in Ordinance Laboratory at Watertown Arsenal Mass, Fiscal Year 1918, War Department Document 901, 338 pp.

https://books.google.com/books/read...printsec=frontcover&output=reader&pg=GBS.PA25

I have copied a few of the Watertown summaries. Some maybe duplicative of those in Hatcher’s Notebook, I invite posters to point out the duplicates.

Examination of Receivers from United States Rifles Model of 1903, burst during Navy Target Practice

Conclusions:

One of the receivers was neither case hardened nor heat treated. It was in the perlitic condition as shown by the micrographs. The structure was very coarse.

Examination of United States Rifle, Caliber 30, Model of 1903, which failed at Camp Greene NC

Conclusions.

The receiver of this rifle had not been properly heat treated prior to being put in service. Microscopic examination showed the metal to be very coarsely crystalline and the structure was that obtained by cooling at a fairly rapid rate from a high temperature. The metal was very brittle under impact, as evidenced by its being readily broken when struck a light blow with a hammer.

Broken Bolts from United States Rifle, Caliber 0.30 Model of 1903

Object: The object of this investigation was to make a complete examination of these two bolts and if possible determine the cause of failure.

Conclusions: It is the conclusion of this laboratory that the failure of both of these bolts is due to the same factor. Both were very hard and brittle and their resistance to sudden impact was very low, as could be ascertained by securely fastening the metal in a vise and striking light blows with a hammer. the brinell hardess number on one of these was 430 and on the other it was 489. these structure of both was martensitic. This structure is characteristic of very brittle material

The chemical composition of these bolts is not within the specified limits with regard to carbon, manganese, and silicon

Investigation of cause of failure of United States rifle Model of 1903, No 108 448, which failed in target practice at Camp Shelby

Conclusions:

It is the conclusion of the laboratory that the failure of this rifle was due, at least partially, if not entirely to defective material composing the barrel. Chemical analysis shows the phosphorus to be 0.083, which is entirely too high and should not be allowed. The metal is very severely banded or streaked longitudinally, as shown by etching polished sections with Stead's reagent. Nonmetallic inclusions were present in considerable quantity and were greatly elongated in the longitudinal direction of the barrel.

The weakening effect of these streaks, rich in phosphorus and containing a large amount of nonmetallic inclusions is particularly apparent under shock. The brittleness under sudden impact caused by high phosphorus and nonmetallic inclusions, especially when in the banded condition, is without doubt the predominating factor contributing directly to the failure of this rifle. The metal of the receiver was very hard and brittle, as can be at once understood by observing micrograph 4215 at 500 diameters , which shows the structure to be martensitic.

A couple of issues fall out, and they are not as simple as a morality play between virtuous Army Ordnance Officer's and villainous forge shop workers. Firstly, the materials they are using are inconsistent and don't meet specifications. . They don't have an incoming material inspection nor a material certification of incoming materials. I know from historical sources that the materials of the age were widely inconsistent, and the chemical analyses by Watertown shows that. These are plain carbon steels with slag, inclusions, high amounts of Phosphors or Sulfur, and all of these defects weaken the end product. I remember Colt had a metallurgical department that performed chemical analysis of the steels from Colt vendors. These Arsenals don’t order steel in 10 pound, 20 pound lots, they order steel in lots of 100,000 pounds or more. We are talking about costs in the $250,000 dollars per order. Why did not Springfield Armory require a chemical test as part of the purchase order or do it in house? Heat treatment temperatures are based on the percentage of carbon in the steel and the heat treatment is specific to the carbon content. Improper carbon content results in a improper heat treatment, and the end result is a part with improper material properties for the application. Like too hard, too soft.

And, rifles are being proofed and shipped out that don’t have heat treated receivers! That shows an out of control production line. This in itself is a huge topic, how to get a production line that produces good product, not a mix of good, bad, sort of good but not too bad product. The Army’s factories were mismanaged and behind the times, even for WW1 factory. No wonder that one third of the rifles produced were structurally deficient.

As to shooting one of these rifles, understand that they are old, have an unknown number of rounds through them. Whatever fatigue life was in the things when they were new, has been used up through the years. If the receiver or bolt fails, the M1903 action has virtually no shooter protection features. Gas will go down the firing pin shaft directly into your eyes. Escaping gas is not funneled or controlled, like the breech of a M700 Remington, often the receiver ring is blown off. There will be chunks and pieces of metal flying around and at someone died once.

Low number 03 failure

https://www.facebook.com/groups/1903loverscollectors/

"13 grains of unique 200 grain lead bullet cci 200 primers. This is the case I beat out of the chamber"

"The bolt looks to be undamaged. Took a block and a hammer to get Open and a 1/4 steelrod to get the case out"

"My son is a safe reloaded and has not had any problems with the many hundreds he has loaded"

"The sad part or good part he had just fired 35 full power loads"

"It was a 14 grains of unique with a 311284 bullet cast with lyman #2 alloy and gas checked"

This one came with a lot of pictures:

http://www.gunbroker.com/Auction/ViewItem.aspx?Item=190985391

This item is a Springfield Armory model 1903 rifle that is a good wall hanger. Its been hanging on the wall of the shop for about 22 years. It is that bad a shape it has been blown up. This is a low ser # of 236162, I had this hanging on the wall to show people what would happen if they shot one of the old low ser # rifles with modern ammo. Look at the pictures to see that this is NOT a shoot able rifle. The guy that shot this rifle spend 4 days in the hospital getting metal out of his eye & metal out of his arms. No FFL required. I will send out a email at the close of the bidding, please copy & send back with payment. I’m selling out a gun shop that was in business for over 30 years. More parts & pieces to come. The shop did a lot of general repair & that’s why all the different parts. This and a bunch more that will be coming up for sale were in 4 other old gun shop’s that I’ve bought out over the last 31 year’s.

[/URL

[/URL]

[/URL

[/URL]

[/URL

[/URL]

[/URL

[/URL]

[/URL

[/URL]

[/URL

[/URL]

[/URL

[/URL]

[/URL

[/URL]

[/URL

[/URL]

[/URL

[/URL]

[/URL

[/URL]

[/URL

[/URL]

Jim Watson

Member

Which comes first, the blown casehead or the fractured action? The always suspect Hatcher position is that the case fails, releasing high pressure gas into a weak action.

Are there comparable reports of disintegrating Krag-Jorgensen Models of 1892-1898?

Same material, same heat treat, probably a lot of the same people. 80% of the chamber pressure, half the lockup.

Are there comparable reports of disintegrating Krag-Jorgensen Models of 1892-1898?

Same material, same heat treat, probably a lot of the same people. 80% of the chamber pressure, half the lockup.

Are there comparable reports of disintegrating Krag-Jorgensen Models of 1892-1898?

Same material, same heat treat, probably a lot of the same people. 80% of the chamber pressure, half the lockup.

I found in the text of a book of mine, Civil War Heavy Explosive Ordnance, that the lifetime of a Parrot cannon, used in the Civil War, averaged 310 rounds before it burst, killing its crew and anyone else in the area. If Congress had not recorded the testimony in a Congressional Committee on Ordnance in 1869, that number would be lost to history and I would have been unaware of the dangers of cast iron Parrot cannon. But proving today, just who might have been killed, and how many Parrot guns blew, is impossible. Does not mean it did not happen.

Today, only Army Safety Investigators and Law Enforcement are allowed access to Army Safety Incident reports. I don't know when the Army started keeping or making Safety Incident reports, but I really believe that any safety incident reports dating back to 1892 were disposed of a century ago when they stopped being relevant.

I handled one Krag bolt that had a cracked lug. If anyone wants to search the historical record, this was well known before WW2. Anyone who wants to believe that something is safe because records don't exist, will discover that ignorance does not prevent accidents.

Last edited:

Jim Watson

Member

Cast iron cannons were widely considered to be cheap expedients, hazardous to gunners who could not get a proper gunmetal (bronze) weapon. It did not take official reports for the word to get around.

I have not handled, but have seen reliable reports of many more than one cracked Krag bolt lug. I have not seen anything about a demolished gun. Surely there would be popular media accounts of such, as the numerous wrecked surplus 1903s you share with us. I never heard of anybody hammering Krags into scrap like Dave LeGate at Rifle Magazine did to several 1903s.

I have not handled, but have seen reliable reports of many more than one cracked Krag bolt lug. I have not seen anything about a demolished gun. Surely there would be popular media accounts of such, as the numerous wrecked surplus 1903s you share with us. I never heard of anybody hammering Krags into scrap like Dave LeGate at Rifle Magazine did to several 1903s.

I have not handled, but have seen reliable reports of many more than one cracked Krag bolt lug. I have not seen anything about a demolished gun. Surely there would be popular media accounts of such, as the numerous wrecked surplus 1903s you share with us. I never heard of anybody hammering Krags into scrap like Dave LeGate at Rifle Magazine did to several 1903s.

We would not know about the extent of the single heat treat M1903 accidents if it had not been for Hatcher's Notebook. Hatcher's data ends in 1927, allowing doubters, such as Hugh Uno, to claim that none blew up afterwards. Dr Lyon's essentially makes the same claim. Without Hatcher's first hand knowledge and reference materials, all would have been lost to history and without Hatcher's celebrity none would have been interested in investigating claims of weak receivers.

P.O. Ackley blew up several Krag's, but his data is non replicable because he did not take pressure measurements. Other than the descriptions of how the actions came apart, and they did, there is very little to be learned from Ackley other than the entertainment value. If someone wants to bust Krag actions, they are welcome to it. I an not going to spend any time or money down this path, to scratch someone else's itch.

I am making a case about the risks of the technology at the time. Pre vacuum tube metallurgy and process controls produced inconsistent and highly variable products. People project, all the time, today's technology and living conditions on the past. Totally forgotten are the number of people who died from simple infections in those pre penicillin times, the typhoid, cholera, yellow fever, and killer flu's epidemics. I never met anyone who died from tuberculosis, never saw a tombstone that said "died from tuberculosis", so maybe claims that one out of every seven people died from tuberculosis is fake news.

Last edited:

Maj Dad

Member

No one was ever killed by an 03 blow up. Two or three soldiers lost an eye, but there were no failures after about 1926, and the total number was very low. Don't take my word - do some research. I can reference a comprehensive research paper on my laptop tomorrow, but in the interim, know that during WW2 no failures occurred with any low number rifles, SA or RIA.Is it a low number gun? under 285,507 or there about. The first 03s made used a single heat treat for the receiver. There were problems, as in they could shatter upon firing. The number that did was a tiny fraction of one percent, but it did kill some people. Some people refuse to shoot them, I shoot mine all the time....with reduced loads. You must remember the "low number" guns had to pass proof at 70,000 PSI, and we went through WW I with low numbered guns, where the gun achieved its legendary status. If your gun is a low number gun it's up to you whether or not to use factory ammo but if it shows a lot of obvious wear, well, its probably had a lot of rounds put through it already. My 03 was proved at the Arsenal, sent off to war, and rebuilt at the San Antonio Arsenal during WW II. It was re-barreled there and proved again with another 70,000 PSI pill!! So here is a low numbered gun that was proved TWICE and survived just fine.

If your gun is above 285507 you have nothing to ponder about. Enjoy

Almost forgot....Welcome to the monkey house

Jim Watson

Member

Be interesting to see that comprehensive research paper to compare with Slamfire's accounts of 03s going up in a cloud of smoke and coming down in a shower of nuts and bolts.

Maj Dad

Member

Slamfire quoted the reference (Dr. Lyons paper) I had in mind. I still put credence in his conclusions, but all observations are input for your own conclusion. You are at much greater risk of injury driving to the store (trite, but true) than from an exploding rifle - we all weigh risk and make decisions.

Last edited:

Jim Watson

Member

What I thought. Slamfire works hard to debunk Lyons, I had hoped there was another report.

MY 1903 is a Mk I with "double heat treat." No better material but more careful processing.

MY 1903 is a Mk I with "double heat treat." No better material but more careful processing.

NIGHTLORD40K

Member

If the rattle is only present when the striker is cocked (and you've eliminated the butt trap theory), I suspect a broken or poorly fitted two piece firing pin. Could be the ejector, but I gave all 3 of mine a good shaking couldn't hear it.

- Status

-

Not open for further replies.

Similar threads

- Replies

- 11

- Views

- 2K

- Replies

- 14

- Views

- 973