Hi All,

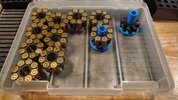

I've been a quiet lurker for a while and thought I'd make a post just to contribute. Anyone who shoots and reloads .45 ACP is very well aware of the cursed small pistol primer cases that seem to pop up regularly in range brass, and even in the stuff we buy. In addition to eyeballing them, there are many methods to sort LPP and SPP brass, some of which are a little more tedious than others. I designed and printed a sorting tray that is easy to load with 100 cases (put it in a tight fitting box, drop in the decapped cases and shake.) The SPP brass stands proud about 1/16", while the LPP brass lays flush to the grid. Then, I just use a pair of tweezers to pull one size or the other, depending on which has less. I don't pinch the case wall, rather insert the tweezer and let it expand to grip the case and extract. I'll be happy to share the .STL and .scad files for anyone wanting to print one...just PM me. I recommend using a resolution of .16mm or better since the tolerances are kind of tight (it does take a long time to print, but it's worth it.) I don't want to publish this on Thingiverse as there are too many people who would just steal the design and sell it on Ebay. Hope you find it as useful as I did.

Ed

View attachment 1207277

View attachment 1207278