M100C

Member

Oh boy, I bet that subject line gets all kinds of attention! Let me explain ...

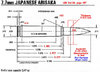

I was talking to a friend (who is a retired gunsmith) about an Arisaka 99 I picked up recently. It is a late gun, and does not have a bolt marking, so I am being cautious about headspace. I see there are headspace gauges for 7.7 Japanese, but I am not finding anywhere I can rent a field gauge, and I am reading woes of many guns that close on no-go gauges. Some say not to worry. Others say fire the gun with a long rope to the trigger (the picture of this made me laugh out loud):

http://forums.gunboards.com/showthread.php?334998-7-7-Field-Gauge

He explained he has headspaced using primers in a pinch. He seats the primer just far enough to still be able to slide a new case out of the shellholder. Then, he chambers the case, and cams the bolt shut slowly and fully. Finally, he uses a depth gauge to measure the depth from the witness mark on the primer to the case head.

After getting past the worry I had for work he has done for me ... ... and, with no one watching, I tried this, and it gives me 0.005". It looks right and good. Here is the question:

... and, with no one watching, I tried this, and it gives me 0.005". It looks right and good. Here is the question:

This is a direct measure of headspace using cases I plan to use, and in the chamber from which they will be fired. While unorthodox, I am not finding anything technically wrong here. What are your thoughts?

Take care,

Chris

I was talking to a friend (who is a retired gunsmith) about an Arisaka 99 I picked up recently. It is a late gun, and does not have a bolt marking, so I am being cautious about headspace. I see there are headspace gauges for 7.7 Japanese, but I am not finding anywhere I can rent a field gauge, and I am reading woes of many guns that close on no-go gauges. Some say not to worry. Others say fire the gun with a long rope to the trigger (the picture of this made me laugh out loud):

http://forums.gunboards.com/showthread.php?334998-7-7-Field-Gauge

He explained he has headspaced using primers in a pinch. He seats the primer just far enough to still be able to slide a new case out of the shellholder. Then, he chambers the case, and cams the bolt shut slowly and fully. Finally, he uses a depth gauge to measure the depth from the witness mark on the primer to the case head.

After getting past the worry I had for work he has done for me ...

This is a direct measure of headspace using cases I plan to use, and in the chamber from which they will be fired. While unorthodox, I am not finding anything technically wrong here. What are your thoughts?

Take care,

Chris