GW Staar

Member

- Joined

- Feb 26, 2009

- Messages

- 3,691

This thread is for Lee Progressive owners (and others) who want to collate RIFLE brass without breaking the bank….after all that’s why you bought Lee’s fine presses in the first place.

I built this one for a Lee owner, but I use a similar one for my two RCBS progressives. My intention this time was to use readily available (inexpensive) parts, (Lee and Home Depot and Amazon) with no need for casting.

Those experimenting with 3d printing could conceivably make the collator, copying the "features", with one print.....if I had one I might have been tempted to try, but I can't get those cheaply at Home Depot.

This is probably my last project of this sort that I will be posting here as I am winding down. I know it won't be popular with the blue crowd who can spend lots of money on the hobby, but that's okay....it's pointed at simpler folk like me.

I will say that it's faster to set up and use than the expensive electric collators and can keep me in cases on my progressives just as well....especially with the longer thinline tubes I use.

Lee has not made a version of their little $12 collator to feed rifle brass, yet their Load Master could use one….so could their sweet little Auto Breech Lock Pro.

Yes, I know the ABLP can only load .223 with the auto-advance in place……however……the Dillon 550 doesn’t do auto-advance at all….and many load .308 on those just fine….

So, what’s to stop ABLP owners from removing the auto-advance, temporarily, so they can load .308? Or even just speed up .223 or similar, with a simple cheap add-on for a Lee collator?

First you need to buy an extra $12 collator, and the Universal Feeder that allows .45 acp and .308 cases to drop through. ($24?)

The Universal can be passed from pistol collator to rifle collator easy enough, so you only need one of those.

Then make a trip to Home Depot and buy a 2 gallon bucket, and an egg crate lighting lens. Hint: They nearly always have broken egg crate....bargain for 3/4's off.

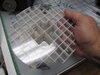

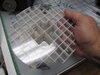

Using flush cutting diagonals cut the red out to make the center piece.....the black is the perimeter to remain.

Do the same this size.....make three of these four cell squares with the red cut out.

Round off the corners inside the cutouts.....don't need to be perfect....just make room for the .308's to drop. Make sure to do that on all four layers before you glue them together.

Cut the bottom out of the bucket (6-1/8" Diameter hole...center it.)

Cut upper bucket off leaving only 2-3/8" tall sides....or there abouts.

This is the goal..... Note that the Lee collator has a rim.....the hole is small enough that the rim keeps the collator from falling through....a keeper is screwed over the top to hold it....see in the steps below...

glue three of the small cutouts to the big cutout......I used markers to make the cutout areas easy to see....but they smeared when I removed them with lacquer thinner (or alcohol). that's why mine is so pretty.....you want pretty or do you want clear instructions?; Notice the epoxy putty blobs on each side....I used the kind with steel fragments mixed so I could drill and tap them....not hard...the 8-32 tap costs a few dollars...or borrow one. I'll show you where and how in a minute. Remember this is a triple-decker on top of the big piece. Use a liquid plastic model cement for glue....use an cheap artist paint brush....hold two pieces together at a time and dip the brush and touch the joints....capillary action sucks the glue into the joint....hold a few seconds release wait a few and do it again....til you have the next picture complete.

You need to cover the egg crate with styrene sheet and again glue. Cut a 5-3/4" circle. I used liquid Tenax, which dries fast, but any liquid glue for styrene or plexiglass works. It welds by desolving the surface of each slightlym then fuzes together. When you go to a hobby store to get the glue, also buy a sheet of styrene....I used clear because I had some, but white is fine, if you think ahead. You have to cut out the "el-shaped" holes in it. Clear is easy to see where to cut, but if you mark them before you get the triple decker glued up, you can do it with opaque white.

Here you can see what the epoxy putty is for....8-32 thumb screws. drill and tap and screw them in. Notice how high the egg crate is above the Lee collator...the triple ply squares provide the correct standoff.

When you are ready to mount the modified Lee collator to the bucket, remove the top thumb screw only and replace it when the collator in place. Notice I drilled three holes in the bucket (more about that in the next picture). Also notice the red mark.....it helps when you are pre-fitting things to make locator marks so you can repeat things.

I built this one for a Lee owner, but I use a similar one for my two RCBS progressives. My intention this time was to use readily available (inexpensive) parts, (Lee and Home Depot and Amazon) with no need for casting.

Those experimenting with 3d printing could conceivably make the collator, copying the "features", with one print.....if I had one I might have been tempted to try, but I can't get those cheaply at Home Depot.

This is probably my last project of this sort that I will be posting here as I am winding down. I know it won't be popular with the blue crowd who can spend lots of money on the hobby, but that's okay....it's pointed at simpler folk like me.

I will say that it's faster to set up and use than the expensive electric collators and can keep me in cases on my progressives just as well....especially with the longer thinline tubes I use.

Lee has not made a version of their little $12 collator to feed rifle brass, yet their Load Master could use one….so could their sweet little Auto Breech Lock Pro.

Yes, I know the ABLP can only load .223 with the auto-advance in place……however……the Dillon 550 doesn’t do auto-advance at all….and many load .308 on those just fine….

So, what’s to stop ABLP owners from removing the auto-advance, temporarily, so they can load .308? Or even just speed up .223 or similar, with a simple cheap add-on for a Lee collator?

First you need to buy an extra $12 collator, and the Universal Feeder that allows .45 acp and .308 cases to drop through. ($24?)

The Universal can be passed from pistol collator to rifle collator easy enough, so you only need one of those.

Then make a trip to Home Depot and buy a 2 gallon bucket, and an egg crate lighting lens. Hint: They nearly always have broken egg crate....bargain for 3/4's off.

Using flush cutting diagonals cut the red out to make the center piece.....the black is the perimeter to remain.

Do the same this size.....make three of these four cell squares with the red cut out.

Round off the corners inside the cutouts.....don't need to be perfect....just make room for the .308's to drop. Make sure to do that on all four layers before you glue them together.

Cut the bottom out of the bucket (6-1/8" Diameter hole...center it.)

Cut upper bucket off leaving only 2-3/8" tall sides....or there abouts.

This is the goal..... Note that the Lee collator has a rim.....the hole is small enough that the rim keeps the collator from falling through....a keeper is screwed over the top to hold it....see in the steps below...

glue three of the small cutouts to the big cutout......I used markers to make the cutout areas easy to see....but they smeared when I removed them with lacquer thinner (or alcohol). that's why mine is so pretty.....you want pretty or do you want clear instructions?; Notice the epoxy putty blobs on each side....I used the kind with steel fragments mixed so I could drill and tap them....not hard...the 8-32 tap costs a few dollars...or borrow one. I'll show you where and how in a minute. Remember this is a triple-decker on top of the big piece. Use a liquid plastic model cement for glue....use an cheap artist paint brush....hold two pieces together at a time and dip the brush and touch the joints....capillary action sucks the glue into the joint....hold a few seconds release wait a few and do it again....til you have the next picture complete.

You need to cover the egg crate with styrene sheet and again glue. Cut a 5-3/4" circle. I used liquid Tenax, which dries fast, but any liquid glue for styrene or plexiglass works. It welds by desolving the surface of each slightlym then fuzes together. When you go to a hobby store to get the glue, also buy a sheet of styrene....I used clear because I had some, but white is fine, if you think ahead. You have to cut out the "el-shaped" holes in it. Clear is easy to see where to cut, but if you mark them before you get the triple decker glued up, you can do it with opaque white.

Here you can see what the epoxy putty is for....8-32 thumb screws. drill and tap and screw them in. Notice how high the egg crate is above the Lee collator...the triple ply squares provide the correct standoff.

When you are ready to mount the modified Lee collator to the bucket, remove the top thumb screw only and replace it when the collator in place. Notice I drilled three holes in the bucket (more about that in the next picture). Also notice the red mark.....it helps when you are pre-fitting things to make locator marks so you can repeat things.

Last edited: