MachIVshooter

Member

Nothing surprising here, riterates and reconfirms that the .308 will achieve 90-95% of its maximum velocity potential in a 20-24" barrel.

Neat video. I learned a few things. I know they said POA shifted horizontally as they shortened the barrel but was there a change in precision?

So I tweak the powder charge to get 2600 fps from a 24 inch barrel. But where they got 2784 fps from the 69 inch barrel QL predicts 3057 fps this tread of the prediction being fast holds until the lines cross ~24 inches. The the QL prediction starting coming in lower than the real world data. MDT got ~2568 at 19-inches and QL predicts 2471 fps.

POA remained the same (if the shooter wasn't trying to influence the test). POI is what changed some.

What a cool video. It was definitely over the top, but they finally got it cut down to where the really useful data were. Neat stuff.

Years ago, Clint Smith did a similar test (but without the extremes) for precision relative to barrel length, but with a standard barrel, cutting it down by an inch with each shot. His work substantiated that length is not a determining factor of precision and that shorter barrels were not necessarily less precise.

POA remained the same (if the shooter wasn't trying to influence the test). POI is what changed some.

QL can only predict what the velocity will be out of a gun because QL does not control for things like internal barrel dimensions that will influence a bullet's velocity.

Actually you can tweak internal bore dimension in QL. If you have an accurate measure of the cross sectional area of your particular barrel's bore there is a place to enter this as opposed to using the default cross section value that is usually taken from the SAAMI spec. It even has a little widget to help you calculate that cross section arear based on measurements of your rifled bore. It the friction model that I think is failing us here (assuming I actually had the right powder). There is very limited ability to adjust the dry friction and viscous losses in the system.

that is what I say being some powders lose more velocity in shorter barrels and some powders lose speed a lot slower in shorter barrelsThe missing variable is powder burn rate. Loading with faster or slower powders could change his results measurably. I'm sure someone playing with Quickloads could figure out an optimum length.

That's what I said in my original QL related post in not so few words...Either way, the program is failing to control for all the variables, hence coming up with predictions that were not a great match for reality.

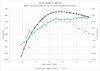

So this was bothering me and I came back to it this evening and kept playing and researching. I have been using QL for 7+ years now and just today I learned that it does indeed have a long barrel model that allows you to add a customizable barrel friction to the model. After turning on this feature and experimenting with the friction number I got a model using 175gr Sierra Match King bullet pushed by 43.5gr of IMR 4064 to replicated the data that MDT showed in their video to within 3.5% or better across the span of all their data points. I used a screen grab from the video and a online program that lets you take an image of graph in turn it into a table of data. I put their converted data and my QuickLoads results into Excel and calculated the error at each length they tested. At the shortest length 19-inch QL was under by 3.48% and at 37 inch QL was over by 2.66%. From 62-69 inches it was off by less than 1%.

The only changes I made to the default 308 Win QuickLoad entry, to make this work, was to increase the case volume slightly (2.6%) and turn on the friction model, setting barrel friction to 3000 psi. Given the default 30 cal bore cross sectional area of .073641 in^2 that equates to about 220lbs of force to push the bullet through the barrel due to friction. Having lodge a bullet or two in a barrel a few times in my day that does not seem like an unreasonable number.

View attachment 1102312

Either way, the program is failing to control for all the variables, hence coming up with predictions that were not a great match for reality.

Did you not see my last post? I got to within 3.5%. For a fluid and thermo simulation that is pretty darn good, and that is guessing what powder they are using. In reality they are probably using a canister powder that is not even in Quickloads or avalable to hobby reloaders but similar to 4064.Quickload only works well within relatively narrow parameters. It is quite bad with straight wall cartridges, for example. It seems 69" barrels are another failing.

Wonder no more!

So...what was the verdict?

The only “criticism” I might see in the model vs. the empirical data is their intersection and relative inflection point locations. The MDT data has an asymptotic approach to an upward bound, while the theoretical model predicts an inflection maxima with a retreat. Being close in modeling is great, but in many cases, “going the wrong direction” and lacking proximal inflection is more indicative of misfit than the raw error.

The model does predict what most folks would tend to assume - that the bullet achieved some maximum velocity and in fact then begins slowing down somewhere within an “almost reasonable” barrel length, but the empirical data shows the bullet remaining to slowly increase in speed for nearly 20” beyond the inflection maxima of the model prediction. In a way of speaking, being off my a small error for relatively large numbers might not be as indicative as the “all up isn’t the same as “up then down”.

This could be coincidental to the single experiment, or it could be indicative that some boundary parameters exist which diverge a “long barrel” from the behavior of a short barrel (normal sub-40” barrels). For example - maybe bore friction decreases after having been drawn for 40” of barrel. Maybe expanding gases aren’t cooling as quickly as modeled, such the in-bore pressure isn’t reduced as much as expected. Maybe, maybe, maybe.

I’ve been saying for a long time that “no practical barrel length will ever achieve full velocity and energy potential for any centerfire cartridge.” This test asserts that. So all of the BS about maximum potential from rounds like 300blk, x39, 6.8 and 6.5 Grendel, 223 and 308, etc that gets kicked around online can look to these results and extrapolate the implications. We pick barrel lengths on practicality for the task, not true maximum potential or powder utilization.

In the empirical data, how many shots were fired the establish the "muzzle velocity"?The only “criticism” I might see in the model vs. the empirical data is their intersection and relative inflection point locations. The MDT data has an asymptotic approach to an upward bound, while the theoretical model predicts an inflection maxima with a retreat. Being close in modeling is great, but in many cases, “going the wrong direction” and lacking proximal inflection is more indicative of misfit than the raw error.

The model does predict what most folks would tend to assume - that the bullet achieved some maximum velocity and in fact then begins slowing down somewhere within an “almost reasonable” barrel length, but the empirical data shows the bullet remaining to slowly increase in speed for nearly 20” beyond the inflection maxima of the model prediction. In a way of speaking, being off my a small error for relatively large numbers might not be as indicative as the “all up isn’t the same as “up then down”.

This could be coincidental to the single experiment, or it could be indicative that some boundary parameters exist which diverge a “long barrel” from the behavior of a short barrel (normal sub-40” barrels). For example - maybe bore friction decreases after having been drawn for 40” of barrel. Maybe expanding gases aren’t cooling as quickly as modeled, such the in-bore pressure isn’t reduced as much as expected. Maybe, maybe, maybe.

I’ve been saying for a long time that “no practical barrel length will ever achieve full velocity and energy potential for any centerfire cartridge.” This test asserts that. So all of the BS about maximum potential from rounds like 300blk, x39, 6.8 and 6.5 Grendel, 223 and 308, etc that gets kicked around online can look to these results and extrapolate the implications. We pick barrel lengths on practicality for the task, not true maximum potential or powder utilization.

The prediction isn’t bad at any particular data point, however looking at the data trend on either end it’s deviating very rapidly such that it appears it would be significantly off if trend continues. Can you run your calculation down to 6 inches? I want to compare it to known data from a cut down test on a 223 I saw awhile back. I know a 223 and 308 are apples and oranges but I want to compare since that’s what I have data for.

In the empirical data, how many shots were fired the establish the "muzzle velocity"?

In the empirical data, did the fact that the barrel was two barrels screwed together make a difference in the velocity behavior?

Does the air mas in front of the bullet make a difference in velocity?