namvet68

Member

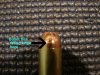

I received my ATI FX45 Titan last week. The First trip to the range did not go well at all. The first 20 rounds of round nose 200 gr. reloads fired without a FTF. When I ran out of those I switched to HSM 230gr. HP(Copper coated lead). These would not load at all. The slide would not go into battery. With the barrel out of the gun, when I would drop a cartridge into the barrel it would not go all the way in. I measured the bullet dimensions and found that it was within specs. I tried some factory 230 gr. Military ball ammo and it would drop right in with room to spare. I built some dummy rounds at different lengths(loa) from 1.220” to 1.275”(max length according to my Lyman book) The short ones would drop right in and the longer ones would not. I tapped on the back of one of the longer rounds to seat it and when I pulled it out found a ring around the bullet where it met the rifling groove (see attached picture of bullet and drawing of barrel). I have been shooting HSM bullets in my other .45’s and have never had a problem. The HSM bullets are fairly flat sided for a few hundreds of and inch above the case when seated above about 1.250 loa . The ball ammo and some other factory ammo I tried started to taper immediately above the case(see attached pic.) and would not hit the rifling shoulder. :banghead:

Attachments

Last edited: