GW Staar

Member

- Joined

- Feb 26, 2009

- Messages

- 3,705

I don’t think I’m the only one, who once invested in a lathe trimmer, who’s now looking for a faster, less monotonous trimming process to relieve that bottleneck, without having to pay $450 for a Giraud. Since the purchase of my first progressive (Pro 2000) I have grown really tired of cranking the ole Forster. (it's the last slow tedious process) Well, I decided to attempt to motorize and "modify" my 40 year-old trimming station to see if I could have and eat cake too.....cheap, delicious....cake, no less!

Basically, my goal was to eliminate the wear and tear on my wrists, already damaged by 20 years of designing buildings with a keyboard and a mouse then building them with a hammer. It had to be easy to build and low tech. (I'm not a machinist or a electronics whiz) Result pictured below:

The funny contraption made of out pipe and PVC, below the bench, is a foot rest/pedal (normally padded with foam pipe insulation [think bare tired feet at the end of a workday]). It connects to the bottom of a 1" PVC riser after first going around a pully under the bench top. (next two pictures)

The PVC canister hanging from the end of the Riser is a dead weight. It has a threaded fitting and plug at the bottom. I filled it with 7 1/2 lbs. of lead weights (bullets, shot, wheel weights whatever). Gravity is free and doesn't get tired like I do. Notice the 1 ¼” PVC pipe at the top. It makes a perfect sleeve for the 1" riser. Also notice the “S” connector … there to make it easy to take the weight off when not in use.

The picture below shows the riser and sleeve terminations topside. The 1 ¼”sleeve comes through the table top and is screwed into the vertical section of the (already-screwed-down) wood base, by drilling lower and upper 1/4" holes clear through the sleeve...then drilling larger holes at the back to allow a counter sink to bevel the hole inside the sleeve for flat head screws. That makes sure no screws interfere with the motion of the riser inside the sleeve. So now the sleeve through the tabletop is fastened to the Trimmer’s new wood base, top & bottom.

I then slightly beveled the top of the sleeve to reduce friction.

Notice the Nicholson File Handle (Home Depot) I use to make tightening the collets effortless. I got the black bins from Home Depot.

The Tee that joins the screw gun and forster shaft is a regular 1 ¼” glue-in Tee with a 1 ¼” to 1" thread reducer glued into the center hole of the Tee.

It so happens that the tee is a perfect tight press fit to the variable-speed ($80) drywall screwgun I bought at Lowes. The only way I’ll get it apart is to cut it off….perfect.

Why'd I pick such a tool? For 3 good reasons! 1.variable-speed, 2. no collet, it’s press and lock. (the Forster power adapter is a press and lock bit), 3. Screwguns have clutches. That means when the tool is raised, the cutter stops turning.

Other things to notice in this picture is that the design of the Alder wood base gives me a perfect mount for all my press tools, trimmer pilots, and a Walmart clamp light. I placed the trimmer station so that the light can do double duty to make sure I can see well while using the Pro 2000 press.

Counter support: (Picture above & below) Notice the bracket, piano wire and spring tying the screwgun to the back wall. Since ball bearings are out of the question in this low tech PVC riser design, to keep the thing lowering and raising smoothly to perfection, a counter weight to the heavy screwgun was necessary to keep the riser from binding against the sleeve. With the spring counterweight, its nearly frictionless and works perfectly. Next picture:

I use a simple hose clamp around the S.G.’s switch to set the speed to exactly where I want it…not too fast to burn the blade, not too slow to cut roughly. (about half way worked for me)

Notice the two screws either side of the all thread. That’s to keep the Tee from turning, yet can be removed. I graphited the riser to keep things slick.

The Screw Gun Model can be seen in the next picture.

The picture below shows 3 important things. Vacuum nozzle, Piano Spring Ejector and the FORSTER 3-WAY CUTTER!!

The vacuum (in the store room) keeps brass chips from filling up my collet holder. I hold the hose with a short piece of 1-1/4"PVC with a bit less than half the circumference sawed away; The piece is bolted to a support and the hose is just pressed in.

The Spring Ejector flips a trimmed, chamfered,and deburred case into the black bin. (thanks to the 3-way cutter) As I built this, Forster is making 3 cutters, .223, .243, and .308. The street price, $50 ea. More cutters is supposed to be coming.

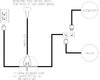

My trimmer doesn't run continuously like a Giraud. I bought this momentary switch from Radio Shack. Press the button with your right hand, watch the trimmings come off, when the brass quits flying you’re done. You let go of the switch, release the lever, and the brass flips into the bin. Wiring diagram below.

Weight under the Bench: 18” of 1 ¼” PVC glue cap at one end (screw on the “I” bolt first) . Then glue a 1 ¼” coupler (glue ends) Then glue a 2” threaded plug over the coupler.

I just used boolits for weight until I collected enough range lead.

Last edited: