BushMaster-15

member

Maybe the powder manufacturer's are removing more of the acid out of the powder, than they used to. When this ad was put in print, Hercules was bragging about a 25 year shelf life:

I have dumped out kegs of powder from the 1990's. My AA4064 went bad

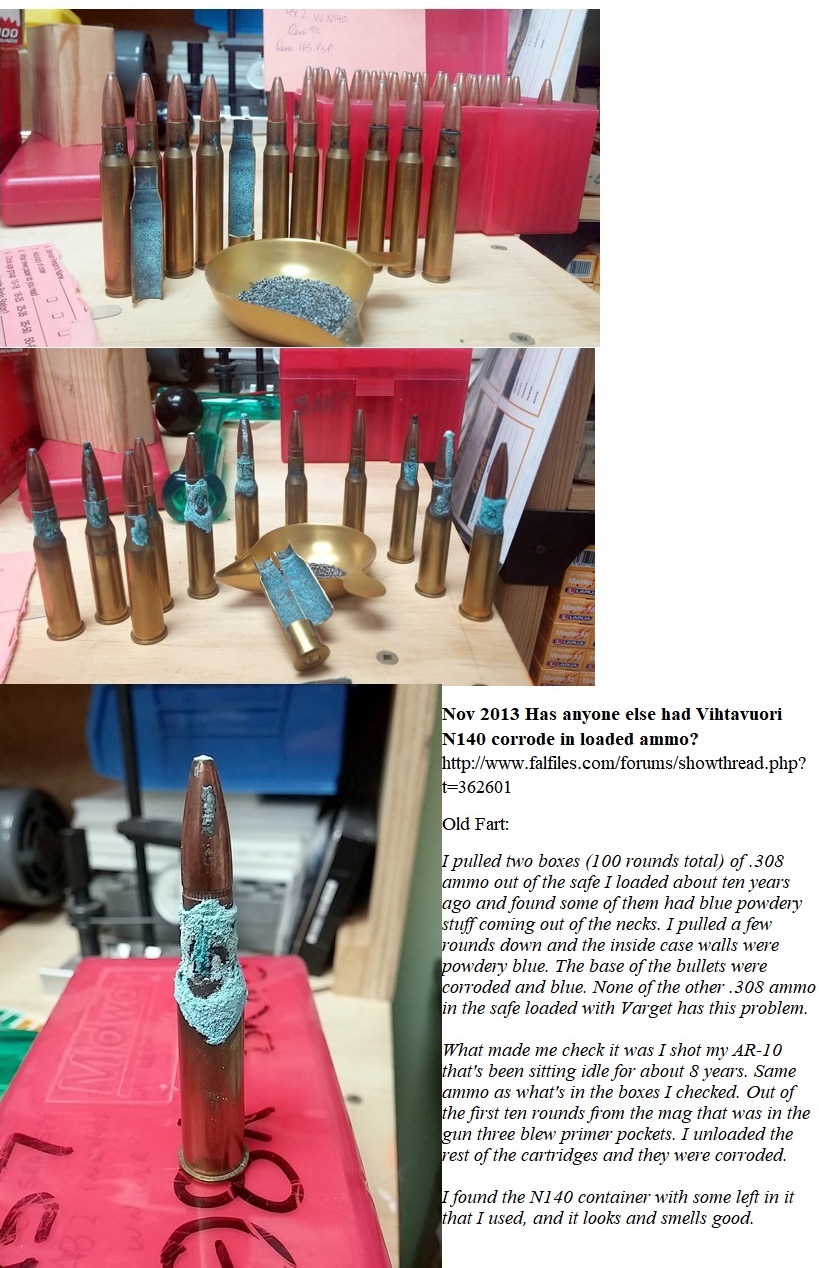

and so did this

a friend gave me this picture. Powder from 1972

this was interesting

My advice: uncork your bottles and sniff them. Also monitor ammunition loaded for years. If you see case neck cracks in loaded ammunition, might be due to powder deterioration. Ditto if there are lots of cracks in fired ammunition.

pulled surplus powder was a bad idea. I tossed out kegs of the stuff. The reason it had been pulled was that it was beyond safe storage limits.

MY advice ; Keep powder in it's own container ,use some inert plastic or glass object to displace air inside the container , " IF " You anticipate 10-20 or more years storage of a used powder . Otherwise SHOOT IT UP sooner .

The nitric and sulfuric acidic compounds WILL deteriorate over time ,HOW powder and QUANTITY of powder Stored determine WHEN . Aka DECADES IF properly stored . A powder will punk or degrade lose energy ,slower in velocity before it fumes in most cases . So if POA and POI don't jive with previously known loads ,use that powder up for range plinkers .

Modern smokeless powder formulations have CHANGED since I batched . Not necessarily the actual Nitroglycerin or cellulose but suppressant stabilizers and to an extent even the graphite coating . Much more stable than years past . Powder best behaves cool and dry ,water absorbent or Hygroscopic for sure is VERY BAD . So NO high humidity or storage near open water sources .

Unless one is exposing powder to extreme Temp and humidity for extended periods ,it should handle it fine .

Borrowed ,so I didn't have to write everything out :

Smokeless powder consists of nitrocellulose (single-base powders), frequently combined with up to 50 percent nitroglycerin (double-base powders), and sometimes nitroglycerin and nitroguanidine (triple-base), corned into small spherical balls or extruded into cylinders or flakes using solvents such as ether. Other minor ingredients, such as stabilizers and ballistic modifiers, are also added. Double-base propellants are common in handgun and rifle ammunition. Triple-base propellants are more common in artillery guns.

The reason that they are smokeless is that the combustion products are mainly gaseous, compared to around 55% solid products for black powder (potassium carbonate, potassium sulfate etc).

Smokeless powder burns only on the surfaces of the granules, flakes or cylinders - described as granules for short. Larger granules burn more slowly, and the burn rate is further controlled by flame-deterrent coatings which retard burning slightly. The intent is to regulate the burn rate so that a more or less constant pressure is exerted on the propelled projectile as long as it is in the barrel so as to obtain the highest velocity. Cannon powder has the largest granules, up to thumb-sized cylinders with seven perforations (one central and the other six in a circle halfway to the outside of the cylinder's end faces). The perforations stabilize the burn rate because as the outside burns inward (thus shrinking the burning surface area) the inside is burning outward (thus increasing the burning surface area, but faster, so as to fill up the increasing volume of barrel presented by the departing projectile). Fast-burning pistol powders are made by extruding shapes with more area such as flakes or by flattening the spherical granules. Drying is usually performed under a vacuum. The solvents are condensed and recycled. The granules are also coated with graphite to prevent static electricity sparks from causing undesired ignitions.

Single and double-base smokeless powders now make up the vast majority of propellants used in firearms. They are so common that most modern references to "gunpowder" refer to a smokeless powder, particularly when referring to small arms ammunition.

Instability and stabilization

Nitrocellulose deteriorates with time, yielding acidic byproducts. Those byproducts catalyze the further deterioration, increasing its rate. The released heat, in case of bulk storage of the powder, or too large blocks of solid propellant, can cause self-ignition of the material. Single-base nitrocellulose propellants are most susceptible to degradation; double-base and triple-base propellants tend to deteriorate more slowly. To neutralize the decomposition products, which could otherwise cause corrosion of metals of the cartridges and gun barrels, calcium carbonate is added to some formulations.

To prevent buildup of the deterioration products, stabilizers are added. 2-Nitrodiphenylamine is one of the most common stabilizers used. Others are 4-nitrodiphenylamine, N-nitrosodiphenylamine, N-methyl-p-nitroaniline, and diphenylamine. The stabilizers are added in the amount of 0.5-2% of the total amount of the formulation; higher amounts tend to degrade its ballistic properties. The amount of the stabilizer is depleted with time. Propellants in storage should be periodically tested on the remaining amount of stabilizer, as its depletion may lead to autoignition of the propellant.

Smokeless propellant components

The propellant formulations may contain various energetic and auxiliary components:

- Propellants:

- Nitrocellulose, an energetic component of most smokeless propellants

- Nitroglycerin, an energetic component of double-base and triple-base formulations

- Nitroguanidine, a component of triple-base formulations

- Plasticizers, to make the grains less brittle

- Dibutyl phthalate

- Polyester adipate

- Dinitrotoluene (toxic, carcinogen, obsoleted)

- Binders, to hold the grain shape

- Rosin

- Ethyl acetate

- Stabilizers, to prevent or slow down self-decomposition

- Diphenylamine

- 2-Nitrodiphenylamine

- 4-nitrodiphenylamine

- N-nitrosodiphenylamine

- N-methyl-p-nitroaniline