Finely got out to do a little more testing with the Mihec "hunter" bullet in the 308w. Been meaning to do testing with different bullets using bl-c2. I've done a little testing in the past with it and it showed promise. Todays target.

While it doesn't look like much that target is actually very informative. I didn't have a lot of pc'd bullet and didn't bring a chronograph. But I will when I do the next outing retesting 34gr and up to see when the load blows out. The bl-c2 loads should be faster then the 2400fps+ rl-7 loads

The 32gr load was a 10-shot group 1 7/8" x 1 1/2" outside to outside round group

The 33gr load was a 10shot group 2 1/4" x 2" outside to outside round group

The 34gr load was only a 7-shot group (ran out of pc'd bullets) 2 5/8" x 1 11/4" outside to outside groups starting to go horizontal

The bottom 34gr load was with a traditionally lubed hunter bullet. 10-shot group 2 1/4" x 1 1/2". Stinkin flier!!! 9 shots in that group were 1 3/8" x 1 1/8"

On the right is 2 different 10-shot groups using rl-7 and the pc'd hunter bullets. Both groups were 30gr of rl-7. What the 2 groups are showing is how the difference in the torque settings on the hold down screws can and will affect the groups size/accuracy.

The top 10-shot group of the 30gr of rl-7 was shot with 40 in lb's of torque 3 1/2" x 1 1/8"

The bottom 10-shot group of the 30gr of rl-7 was shot with 45 in lb's of torque 2 1/4" x 2 3/4"

The 30gr rl-7 loads are not the greatest but they are repeatable.

The last testing I'll do with this hunter bullet is with the traditionally cast/lubed version and bl-c2.

Hitting the design wall with the Mihec hunter bullet:

I've tested several different powders with this bullet an any time it starts to get pushed over 2400fps the groups are +/- 2" x 2". The issue with the bullet is mainly the grease groove and while minor the wiper groove.

The gas check shank is .283" The grease groove is .250". That narrow 1/4" of lead left in the grease groove stem is what is steering the bullet. This is why the bl-c2 will out perform the rl-7 with high pressure/hv loads. The faster burning rl-7 has more of a smack/pressure spike when the bullet is launched. The slower burning bl-c2 has more of a push, lower short start pressure.

The 308w that I'm using has a 30" light standard puma bbl from shilen on it. Basically it's a long tuning fork. With jacketed bullets you set the torques and forget it. With cast bullets you can see the ladder groups start to go horizontal or vertical and can be brought back by adjusting the torques on the action screws. The weaker the bullet design the more "play" in the bullet's length and how quickly that bullets length changes in the bbl.

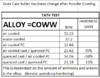

The rotational torque/stresses put on the bullets themselves is impressive. That 2400fps+ rl-7 load has that bullet spinning at 123,500 rpm's+. The real challenge is trying to get the pc'd bullets alloy to match the traditionally lubed/cast bullets. I'm using air cooled bullets/14bhn for the traditionally cast/lubed bullets. The pc'd bullets are water dropped then pc'd & air cooled. A chart showing how the pc'ing process affects the bhn of the bullet.

While the air cooled cast bullets should be the same as the water dropped pc'd bullets they aren't. The pc'd bullets alloy is a little softer. That's why the pc'd bullets tend to have more velocity for the same load compared to their traditionally lubed/cast counterparts. Softer alloy and the pc coating seals better and faster making them more efficient. That is why the pc'd 34gr load started to blow out while the 34gr traditional bullet did not.

All this has to do with the bullet design. Stronger bullet designs like the lee 312/160 tl bullet or the NEO mxb bullet are no where near as picky

While it doesn't look like much that target is actually very informative. I didn't have a lot of pc'd bullet and didn't bring a chronograph. But I will when I do the next outing retesting 34gr and up to see when the load blows out. The bl-c2 loads should be faster then the 2400fps+ rl-7 loads

The 32gr load was a 10-shot group 1 7/8" x 1 1/2" outside to outside round group

The 33gr load was a 10shot group 2 1/4" x 2" outside to outside round group

The 34gr load was only a 7-shot group (ran out of pc'd bullets) 2 5/8" x 1 11/4" outside to outside groups starting to go horizontal

The bottom 34gr load was with a traditionally lubed hunter bullet. 10-shot group 2 1/4" x 1 1/2". Stinkin flier!!! 9 shots in that group were 1 3/8" x 1 1/8"

On the right is 2 different 10-shot groups using rl-7 and the pc'd hunter bullets. Both groups were 30gr of rl-7. What the 2 groups are showing is how the difference in the torque settings on the hold down screws can and will affect the groups size/accuracy.

The top 10-shot group of the 30gr of rl-7 was shot with 40 in lb's of torque 3 1/2" x 1 1/8"

The bottom 10-shot group of the 30gr of rl-7 was shot with 45 in lb's of torque 2 1/4" x 2 3/4"

The 30gr rl-7 loads are not the greatest but they are repeatable.

The last testing I'll do with this hunter bullet is with the traditionally cast/lubed version and bl-c2.

Hitting the design wall with the Mihec hunter bullet:

I've tested several different powders with this bullet an any time it starts to get pushed over 2400fps the groups are +/- 2" x 2". The issue with the bullet is mainly the grease groove and while minor the wiper groove.

The gas check shank is .283" The grease groove is .250". That narrow 1/4" of lead left in the grease groove stem is what is steering the bullet. This is why the bl-c2 will out perform the rl-7 with high pressure/hv loads. The faster burning rl-7 has more of a smack/pressure spike when the bullet is launched. The slower burning bl-c2 has more of a push, lower short start pressure.

The 308w that I'm using has a 30" light standard puma bbl from shilen on it. Basically it's a long tuning fork. With jacketed bullets you set the torques and forget it. With cast bullets you can see the ladder groups start to go horizontal or vertical and can be brought back by adjusting the torques on the action screws. The weaker the bullet design the more "play" in the bullet's length and how quickly that bullets length changes in the bbl.

The rotational torque/stresses put on the bullets themselves is impressive. That 2400fps+ rl-7 load has that bullet spinning at 123,500 rpm's+. The real challenge is trying to get the pc'd bullets alloy to match the traditionally lubed/cast bullets. I'm using air cooled bullets/14bhn for the traditionally cast/lubed bullets. The pc'd bullets are water dropped then pc'd & air cooled. A chart showing how the pc'ing process affects the bhn of the bullet.

While the air cooled cast bullets should be the same as the water dropped pc'd bullets they aren't. The pc'd bullets alloy is a little softer. That's why the pc'd bullets tend to have more velocity for the same load compared to their traditionally lubed/cast counterparts. Softer alloy and the pc coating seals better and faster making them more efficient. That is why the pc'd 34gr load started to blow out while the 34gr traditional bullet did not.

All this has to do with the bullet design. Stronger bullet designs like the lee 312/160 tl bullet or the NEO mxb bullet are no where near as picky