Alllen Bundy

Member

I bought a new Sig P365XL and needed to setup a lockbox for it. While my original lockbox setup works fairly well with my P365, it has a number of flaws to address. The most serious flaw is that the 16 gauge steel that the lockbox is made from is insufficient to stop a 9 mm bullet if the pistol fires for whatever reason, be it a fire or otherwise. And in the very unlikely chance that the pistol did fire I didn't want it to be able to chamber another round and fire again.

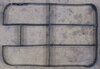

From the testing that I have seen a 9 mm bullet can penetrate 2 layers of 16 gauge mild steel and dent a 3rd layer. So I added 3 layers of 304 alloy stainless steel in front of the barrel making a total of 4 layers of 16 gauge steel, including the lockbox, to stop a bullet. I don't have access to a box and pan brake or even a heavy duty vise in my apartment. So I clamped two heavy blocks of metal around the stainless steel and hammered the stainless steel over the metal blocks to form the 90° corners. The curved portion of the bullet stop was bent over a large wooden dowel. It took quite a bit of futzing to get everything into shape and fit properly. Inside this stainless steel bullet stop I store a magazine loader.

I added another curved piece of stainless steel to the lockbox to make it flush with the thickness of the steel hinge. I used the original JB Weld Higher Strength formula epoxy to hold this curved stainless steel piece onto the lockbox. I do need to get some grey paint to touch up the areas where I stripped the paint to allow the epoxy to bond the curved stainless steel corner piece directly to the steel lockbox.

Some people are going to say that I'm crazy for making the effort to do this. But I don't want to take the chance of a fireman or anyone else getting shot if a fire cooks off a round inside the firing chamber of my pistol. Most people will never have their house or apartment burn down. But I am living in an apartment two blocks from the apartment that my sister used to live in before her apartment building burned down. Life is unpredictable.

I used ABS plastic sheet to form the magazine storage frame and used ABS solvent based cement to glue the pieces together. I made the new frame taller than my first version and it now completely protects the bullet tips. I glued the stainless steel bullet stop to the ABS plastic frame with JB Weld Plastic Bonder, which is a 2-part urethane glue.

In my first lockbox setup I added an ABS plastic guard around the cam lock area to prevent the pistol from being gouged by the cam lock. But that guard interfered with my thumb when I was removing the pistol from the lockbox. I had formed the ABS sheet freehand while heating it. But that was not precise enough so I made a wooden forming jig and was able to make the plastic guard much smaller. I also cut a portion of the guard away for better thumb clearance when I grab the pistol from the lockbox.

Previously I formed the curved corner pieces of ABS freehand with the heat gun, but that looked sloppy. This time I found some round tubing that was just the right size for a bending form for the corners.

I also added a 16 gauge stainless steel panel at the rear of the slide to prevent it from moving rearward far enough to chamber a round. I glued this stainless steel panel to the ABS guard with JB Weld Plastic Bonder.

I wanted a better way to hold a few extra cartridges in place than the slots that I cut into the foam on my earlier version of the lockbox setup. I didn't have any hole punches that were the correct size. But then I realized that the neck of a 30.06 shell case is just a bit smaller than a 9 mm shellcase and that hole size would be perfect to hold 9 mm cartridges in place. I used a diamond whetstone to grind a bevel around the neck of the shellcase to make it sharp. I was then able to use the shellcase neck to punch through the 3 layers of foam. There was enough room for three holes. There is an open area in the foam just forward of the grip, but cartridges in that location would get in the way of grabbing the pistol.

I did cut a slot into the foam underneath the muzzle end of the grip module to hold a chamber flag when not in use. With hindsight I should have used the shellcase to punch a hole at each end and then used a scalpel to cut the slot between the two holes. and it would have looked cleaner.

You can see by the photos that while there is enough room inside the lockbox for the pistol to have a chamber flag installed, there is not enough room for the slide to fully retract with either the P365 or P365XL. That will prevent the slide from cycling in the unlikely event that the pistol fired inside the lockbox.

This is secure enough to keep most children out of the lockbox. But I can pick the lock in 15 seconds using only a couple of small screwdrivers. But I also want to key all four of my lockboxes alike so I need to change the locks anyway. I plan to replace the locks with the tubular key style cam locks which are slightly more secure.

The lockbox comes with a steel cable that you can use to secure the box to something. It isn't particularly secure, but it is marginally adequate for very short term storage if I need to go into a building that prohibits firearms. Usually the lockbox would be inside one of my bicycle bags with the cable wrapped around the bike frame going to the bike lock. The black vinyl covered steel cable looks like a brake or shifter cable housing on my bicycle so it doesn't really attract much attention.

The foam inside the box does a great job of holding everything in place without any rattling. I used 3M Super 74 Foam Fast Adhesive to glue multiple layers of foam together. FYI, I bought this adhesive spray can back in 1992 and it still works.

Last edited: