OP never stated what firearm he was using.

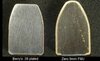

I see this effect, but only when I shoot the same loads in my JRC Carbine which uses a blowback system, which means you would want a faster burning powder or you will see soot.

I use BE-86 in my pistols with no soot, but as soon as I shoot the same ammo in my JRC, its all sooty. But still works great.

All the information from others above is correct, you just have to figure it out, powder, bullet seating, firearm one of these adjustments will fix it.

I see this effect, but only when I shoot the same loads in my JRC Carbine which uses a blowback system, which means you would want a faster burning powder or you will see soot.

I use BE-86 in my pistols with no soot, but as soon as I shoot the same ammo in my JRC, its all sooty. But still works great.

All the information from others above is correct, you just have to figure it out, powder, bullet seating, firearm one of these adjustments will fix it.