LarsUlmann

Member

Hi Guys,

I got so much from this forum in the past so I am glad to finally give back.

I just want to share a solution for a problem to address the cylinder pin lock on an 1858 Remington in case that the loading lever is removed (not used) anymore.

I can imagine 3 major cases for that:

- to install a scope mount

- to shorten the barrel

- to have a lightning fast cylinder reload

After a long search I found a costly solution for that, provided by Howell as in the link below.

http://www.howellarms.com/parts/1858-remington-cylinder-pin-quick-release

Since I am located in the EU there is no possibility for me to buy this piece of iron from the USA at all, and the only dealer that sells it in EU is having too heavy shipment fees so again it is a no-go for me.

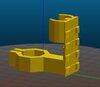

Fortunately I have a 3D printer at home so it took only several hours (7 tries till the final version) to draw and print out one for myself. This version has 2 advantages vs. the Howell-type latch:

- it unlocks/locks automatically so no need to push or pull any part of it

- it uses a videly available spring that can be obtained from any ball pen laying around

As an extra it is much shorter than any other version so when using a black PLA it is remains practically unnoticed on the gun.

I have used the Sketchup Free v.8 for the drawing.

I am attaching the Sketchup file and the STL file so anyone can print it at home.

Note that after the item is printed the small hole may need to get a bit of reaming so it can freely move on the loading lever screw.

As of the spring, simply use any available at home, just cut it upon your need.

NOTE: I have not tried shooting with this solution yet so I can not tell whether it is durable enough, time will tell. In any case if one does try it before I do just plase share it here.

Regarding the heat, the PLA is starting to melt at around 160C so it is worth to check whether the latch is intact after shooting a few rounds. I am not sure about the newest printing technology but I can imagine there are other materials that melt on a much higher degree.

NOTE: The drawing is based on millimetres so anybody can do the measurements and create an iron or aluminium latch for himself by some hand work easily.

WR, Lars.

I got so much from this forum in the past so I am glad to finally give back.

I just want to share a solution for a problem to address the cylinder pin lock on an 1858 Remington in case that the loading lever is removed (not used) anymore.

I can imagine 3 major cases for that:

- to install a scope mount

- to shorten the barrel

- to have a lightning fast cylinder reload

After a long search I found a costly solution for that, provided by Howell as in the link below.

http://www.howellarms.com/parts/1858-remington-cylinder-pin-quick-release

Since I am located in the EU there is no possibility for me to buy this piece of iron from the USA at all, and the only dealer that sells it in EU is having too heavy shipment fees so again it is a no-go for me.

Fortunately I have a 3D printer at home so it took only several hours (7 tries till the final version) to draw and print out one for myself. This version has 2 advantages vs. the Howell-type latch:

- it unlocks/locks automatically so no need to push or pull any part of it

- it uses a videly available spring that can be obtained from any ball pen laying around

As an extra it is much shorter than any other version so when using a black PLA it is remains practically unnoticed on the gun.

I have used the Sketchup Free v.8 for the drawing.

I am attaching the Sketchup file and the STL file so anyone can print it at home.

Note that after the item is printed the small hole may need to get a bit of reaming so it can freely move on the loading lever screw.

As of the spring, simply use any available at home, just cut it upon your need.

NOTE: I have not tried shooting with this solution yet so I can not tell whether it is durable enough, time will tell. In any case if one does try it before I do just plase share it here.

Regarding the heat, the PLA is starting to melt at around 160C so it is worth to check whether the latch is intact after shooting a few rounds. I am not sure about the newest printing technology but I can imagine there are other materials that melt on a much higher degree.

NOTE: The drawing is based on millimetres so anybody can do the measurements and create an iron or aluminium latch for himself by some hand work easily.

WR, Lars.

Attachments

Last edited: