EddieCoyle

Member

I was setting up to reload some .32 ACP for the first time. I have about 1500 cases of once-fired brass with mixed headstamps sorted by mfg. These were fired from a random mix of guns (some of each brass passed through a Colt 1903, Beretta 1935, CZ 27, Savage 1907, Walther PP, and Beretta 3032 Tomcat). I'm using a new Lee carbide 3-die set.

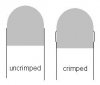

When I was setting up my press (new-style Hornady L-N-L AP) I used a S&B case to make a up dummy round. I set the resizing die to just miss the shell plate, set the expander die so that I could just barely insert about 1/32" of the bullet into the case, set the seating/crimping die for a strong taper crimp and a 0.980" OAL. When I was done, I pushed hard on the end of the bullet and had no setback. So far so good.

Just for the heck of it, I decided to do the same (no primer, no powder) for the other brands of cases. I tried a R-P (Remington) case and when I went to insert the bullet, it DROPPED into the case! What I mean is that I resized the case, belled it, then went to put the bullet in and it almost fell all the way into the case! I reduced the amount of expansion slightly and increased the crimp, but when I pushed (lightly) on the seated and crimped R-P brass dummy round, the bullet would easily push into the case.

I'm loading 0.312", 71gr FMJ bullets, and I measured each one as I was making the dummy rounds and they were all dead-on.

Something is wrong here. I tried a couple of samples of each of the other manufacturer's cases and they were OK, but the Winchester cases would get "set back" unless I put borderline roll crimp on them.

So I measured the wall thickness of some un-resized cases with vernier calipers (1/8" from the top of the case). Here are the thicknesses that I found:

The S&B's case walls are twice as thick as Remington!

The four thickest brands of cases (S&B, FC, Corbon, & CBC) would load fine. I was barely able to get an acceptable round with the Winchester cases. However, the Remington brass is so thin as to be useless.

What I'm guessing is happening is that the resizing die would squeeze the cases down, but the R-P brass is so thin that it won't shrink to an inside diameter sufficient to hold the bullet.

Funny thing is, I was loading some 10mm a couple of weeks ago and had a similar problem with some nickel plated R-P cases. The Starline brass that I had would load fine, but the R-P cases wouldn't hold the bullet. In that case, I had a Lee Factory Crimp Die that I torqued down to enable the R-P brass to hold the bullets.

Has anyone else experienced this with Remington brass?

Is there a die that will undersize the brass so that the R-P stuff will work?

If so, will the undersized die still allow me to load the thicker stuff?

If not, I'm going to avoid R-P brass in the future.

When I was setting up my press (new-style Hornady L-N-L AP) I used a S&B case to make a up dummy round. I set the resizing die to just miss the shell plate, set the expander die so that I could just barely insert about 1/32" of the bullet into the case, set the seating/crimping die for a strong taper crimp and a 0.980" OAL. When I was done, I pushed hard on the end of the bullet and had no setback. So far so good.

Just for the heck of it, I decided to do the same (no primer, no powder) for the other brands of cases. I tried a R-P (Remington) case and when I went to insert the bullet, it DROPPED into the case! What I mean is that I resized the case, belled it, then went to put the bullet in and it almost fell all the way into the case! I reduced the amount of expansion slightly and increased the crimp, but when I pushed (lightly) on the seated and crimped R-P brass dummy round, the bullet would easily push into the case.

I'm loading 0.312", 71gr FMJ bullets, and I measured each one as I was making the dummy rounds and they were all dead-on.

Something is wrong here. I tried a couple of samples of each of the other manufacturer's cases and they were OK, but the Winchester cases would get "set back" unless I put borderline roll crimp on them.

So I measured the wall thickness of some un-resized cases with vernier calipers (1/8" from the top of the case). Here are the thicknesses that I found:

- S&B - 0.010" to 0.013"

- Cor bon - 0.009" to 0.011"

- F C (Federal) - 0.008" to 0.011"

- CBC - 0.008" to 0.010"

- Winchester - 0.007" to 0.008"

- Remington (R-P) - 0.004" to 0.006"

The S&B's case walls are twice as thick as Remington!

The four thickest brands of cases (S&B, FC, Corbon, & CBC) would load fine. I was barely able to get an acceptable round with the Winchester cases. However, the Remington brass is so thin as to be useless.

What I'm guessing is happening is that the resizing die would squeeze the cases down, but the R-P brass is so thin that it won't shrink to an inside diameter sufficient to hold the bullet.

Funny thing is, I was loading some 10mm a couple of weeks ago and had a similar problem with some nickel plated R-P cases. The Starline brass that I had would load fine, but the R-P cases wouldn't hold the bullet. In that case, I had a Lee Factory Crimp Die that I torqued down to enable the R-P brass to hold the bullets.

Has anyone else experienced this with Remington brass?

Is there a die that will undersize the brass so that the R-P stuff will work?

If so, will the undersized die still allow me to load the thicker stuff?

If not, I'm going to avoid R-P brass in the future.