I have decided to purchase a plate carrier (for a bump in the night kind of situation) and have been looking at some plates. I was looking at chase tactical and was wondering if their a quality product? And also I was under the impression that polyethylene plates were heat sensitive but when I contacted them they said they were not does that sound right? Thanks in advance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Polyethylene plates

- Thread starter Actionjrs

- Start date

- Status

-

Not open for further replies.

Our SWAT guys run poly plates, not sure which company though. My current Lt., the former SWAT Sgt., loves them due to their light weight. I am not so sure though... They are thicker than steel or ceramic, sometimes by a considerable amount. But they are lighter. If and when I get some for work I am looking at Lvl IV ceramic for my duty vest. Not as light but a higher protection rating and proven material. I am 5'9 and 220, I'll be ok.

sonicmaster577

member

- Joined

- Sep 8, 2016

- Messages

- 16

Officers now liable to encounter UHMWPE Polymer armored "bumps in the night", since its sold to anyone on the Internet to anyone with a credit card, no questions asked

Why are you making that assumption?

barnbwt

member

- Joined

- Aug 14, 2011

- Messages

- 7,340

Ain't it a damn shame. WhateverOfficers now liable to encounter UHMWPE Polymer armored "bumps in the night", since its sold to anyone on the Internet to anyone with a credit card, no questions asked

Polyethylene is the simplest polymer chain there is, basically. This means that molecularly, it's very much like fine hair, with very few branches or snags to keep the 'mers' or chains from slipping past eachother, and absolutely no cross-linking between the chains. As temps rise, these chains get more and more loosened, and slide by eachother easier, making Polyethylene perhaps the most thermally-sensitive common plastic there is. The saving grace of PE is the fact it is "UHM," or 'ultra high molecular weight,' which means the mer chains are extremely long, and prone to tangling with other chains. The result is sorta-kinda like cross linking seen in more complex polymers that increases strength, a kind of microscopic fiber-based material (though far, far weaker in each strand than something like Kevlar)

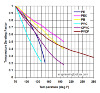

Not specifically how the curvature of PE is reversed toward accelerating weakness, compared to the others, even the weaker PVC

This isn't 'strength' as far as psi or whatever, but it does show how rapidly temperatures weaken polyethylene. Luckily, though, a plate at home for break-in response should be about the same low temp all the time, and just as stable as your cutting boards (same material). Plates put on that were left in your extremely hot trunk in the summer would be the only place it'd even be a question, and even then I suspect the real differential isn't all that much once they've been placed against your body for more than a few moments (very low specific heat for PE). PE is also such a simple compound that it doesn't suffer heat cycle degradation as badly as some materials, so once it cools & the mers stiffen up, it's gonna be the same as when it was new for the most part (unless you're straight up melting it & screwing with the actual crystal structure)

Is the main draw to PE armor that it's cheap? I can think of several other materials that seem naturally better for the application offhand (polyesters, polyamides, aramids, epoxies, acetal; basically most higher-complexity long chain polymers)

- Status

-

Not open for further replies.