You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

-

Not open for further replies.

Lennyjoe

Member

I’ve used AA9, BE86 and so far 800X has shot the best with 125 gr Montana Gold JHP bullets.

vaalpens

Member

- Joined

- Aug 14, 2014

- Messages

- 2,618

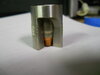

Also, I realized I have some berrys 124 grain Flat Point (not thick plate) and 124 grain Target Hollow Point projectiles. Can they be used in 357 sig loads at regular velocities? Picture attached, with a v-crown on the right.

Yes, you can use the regular plated bullets, but you have to keep the velocities down. This is statement from X-Treme bullets:

"Any velocities over 1200 FPS we recommend either our Heavy Plate Concave Base or Hollow Point products for superior accuracy. We recommend keeping velocities to less than 1500 FPS (Feet Per Second) and using only a light taper crimp"

I have loaded plated bullets and even some ACME coated bullets. The problem with 357sig is, with a 124gr type bullet, you normally will see velocities starting in the +1200fps range. That is when you start losing accuracy with the thinly plated bullets. A better option for plated bullets will probably be 147gr bullets, since you have lower velocities.

The plated bullet I loaded most was the Berry's 124gr HBFPTP. This bullet works well in 9mm.

There are some good bullets out there to use, but with each new bullet, you have to make sure it will fit your magazine and gun. I normally do a few basic things before using a new bullet in 357sig:

- Find a COL that will fit your gun:

- Ogive outside the case.

- Pass the plunk test.

- Fit your magazine

- Cycles through your gun

- Test for setback by cycling it through your gun a few times.

- I normally would also try and push the bullet into the case after the setback test, just to make there is some good neck tension left.

Other bullets that worked well for me were: MG 125gr JHP, Sierra V-Crown 125gr (the V-Crown you show looks more like the 124gr bullet), Zero 125gr JHP, Nosler 124gr JHP.

Here is a picture of both 125gr (left) and 124gr V-Crown bullets:

You will probably need a debulger at some point in time, especially if you buy range brass. I use my 40s&w Lee FCD as a debulger for 357sig.

The COL for 357sig rounds are all over the place. I don't even try and target a specific. I let the bullet dictate what the COL should be. I have loaded COL's of 1.125", 1.135", 1.140" and even 1.150". They all worked, even the 1.150". The 1.150" COL was one of those longer nose JHP's.

I never load pulled bullets in 357sig. I have tried a few times, but the setback test just wasn't consistent enough for me. The pulled bullets weren't wasted, since I would just use them in 9mm.

Have fun and be safe.

Last edited:

kerreckt

Member

Alex G

Member

- Joined

- Dec 30, 2020

- Messages

- 242

I was looking at that one, but it doesn’t show on Berrys website, and when I contacted them they said it was out of production and they didn’t know if they were going to make more.The plated bullet I loaded most was the Berry's 124gr HBFPTP.

Yep, it is. I got some of the 124’s for my 9mm. I see the 125’s have a significantly different profilethe V-Crown you show looks more like the 124gr bullet

Thanks! That looks sweet!Here you go!

Alex G

Member

- Joined

- Dec 30, 2020

- Messages

- 242

Also, it doesn’t look like RMR is even producing these now147gr TCFPMW, 124gr TCFPMW

Any other ideas?

They may produce them in runs. @longdayjake would be the one to ask.Also, it doesn’t look like RMR is even producing these now

Any other ideas?

vaalpens

Member

- Joined

- Aug 14, 2014

- Messages

- 2,618

Also, it doesn’t look like RMR is even producing these now

Any other ideas?

RMR must have pulled them until they catch up with all the orders. The 124gr MPR can still be backordered.

https://www.rmrbullets.com/shop/bul...hollow-point-multi-purpose-round-bullets-new/

It is difficult times to get/find components.

Last edited:

JimKirk

Member

I shoot a bunch RMR 124 grain MPR ...Long Shot, 800x and AA#9 are my most used powders ... but I haven shot many others ...

The Hornady XTP 124 grain is my favorite ...

I shoot a few Hornady XTP 147 grain ....with 800 X ....I can safely get 1300 + fps in my Glock 31...

The Hornady XTP 124 grain is my favorite ...

I shoot a few Hornady XTP 147 grain ....with 800 X ....I can safely get 1300 + fps in my Glock 31...

gojones

Member

Ive use the RMR bullets but the 147 grain is flat based and takes an expander. I really like the everglades 147 grn that are tapered at the bottom and don't have to use an expander. I have two sizers, one a 40 cal carbide and then the steel 357 sig FL. I do not use lube. I use either WSF or BE-86 powder. Have not had any issues. I have started buying pulled primed brass... speer. This solves my primer issue and they shoot fine.

Speaking of loading lead bullets in 357 SIG. I have a Lee's 358-125 mold that I cast and sized the bullets down to .356". Hi-tek coated. Plans are to try them out in 9mm.

I sized and slightly bell mouthed 25 cases. Seated and roll crimped to OAL of 1.145". Dummy rounds.

Cycled them all through 2 guns. A compact and full size frames. All but 2 lost .002" on OAL. The 2 jammed into the feed ramp of the full size. They lost .013".

The flat nose looks to be too wide for reliable feeding. They may not work for 9mm either.

I have some MBCs 124 gr. Truncated nose that I may try next, if they don't see too long.

I have 2 sets of 357 SIG dies. Lee's and RCBS. The RCBS bullet seat can do a slight roll crimp. Not so much with Lee's.

I sized and slightly bell mouthed 25 cases. Seated and roll crimped to OAL of 1.145". Dummy rounds.

Cycled them all through 2 guns. A compact and full size frames. All but 2 lost .002" on OAL. The 2 jammed into the feed ramp of the full size. They lost .013".

The flat nose looks to be too wide for reliable feeding. They may not work for 9mm either.

I have some MBCs 124 gr. Truncated nose that I may try next, if they don't see too long.

I have 2 sets of 357 SIG dies. Lee's and RCBS. The RCBS bullet seat can do a slight roll crimp. Not so much with Lee's.

Alex G

Member

- Joined

- Dec 30, 2020

- Messages

- 242

Speaking of loading lead bullets in 357 SIG. I have a Lee's 358-125 mold that I cast and sized the bullets down to .356". Hi-tek coated. Plans are to try them out in 9mm.

I sized and slightly bell mouthed 25 cases. Seated and roll crimped to OAL of 1.145". Dummy rounds.

Cycled them all through 2 guns. A compact and full size frames. All but 2 lost .002" on OAL. The 2 jammed into the feed ramp of the full size. They lost .013".

The flat nose looks to be too wide for reliable feeding. They may not work for 9mm either.

I have some MBCs 124 gr. Truncated nose that I may try next, if they don't see too long.

I have 2 sets of 357 SIG dies. Lee's and RCBS. The RCBS bullet seat can do a slight roll crimp. Not so much with Lee's.

I’m assuming a slight roll crimp is a valid option with 357 SIG since it headspaces (or can headspace) on the shoulder?

Lennyjoe

Member

I wouldn’t roll crimp any bullet without cannelure. I prefer using a Lee Factory Crimp Die for .357 SigI’m assuming a slight roll crimp is a valid option with 357 SIG since it headspaces (or can headspace) on the shoulder?

That's what I was hoping, and the plunk test confirmed.I’m assuming a slight roll crimp is a valid option with 357 SIG since it headspaces (or can headspace) on the shoulder?

Or a cast bullet that was meant to roll crimp.I wouldn’t roll crimp any bullet without cannelure. I prefer using a Lee Factory Crimp Die for .357 Sig

Lennyjoe

Member

Or a cast bullet that was meant to roll crimp.

Touche

You're point was valid. I doubt if there are many .355-.356" bullets out there that have a cannelure. And then it would probably be useless in 357SIG seating OAL.Touche

Alex G

Member

- Joined

- Dec 30, 2020

- Messages

- 242

Got everything set up, with some 124 grain berrys FP bullets as dummy rounds to get me close for when the actual projectiles get here. I went to deprime/size the brass, and my decapping pin keeps pulling out of the shaft and getting stuck in the case! I’ve got a Redding die set. Any suggestions?

WrongHanded

Member

- Joined

- Jul 6, 2017

- Messages

- 4,771

Got everything set up, with some 124 grain berrys FP bullets as dummy rounds to get me close for when the actual projectiles get here. I went to deprime/size the brass, and my decapping pin keeps pulling out of the shaft and getting stuck in the case! I’ve got a Redding die set. Any suggestions?

Put a deprimed piece of brass in the die to help set the depth of the pin when you tighten it back down.

vaalpens

Member

- Joined

- Aug 14, 2014

- Messages

- 2,618

Got everything set up, with some 124 grain berrys FP bullets as dummy rounds to get me close for when the actual projectiles get here. I went to deprime/size the brass, and my decapping pin keeps pulling out of the shaft and getting stuck in the case! I’ve got a Redding die set. Any suggestions?

Oh the fun of reloading 357sig.

Some of the 357sig cases have smaller flash holes, which could be the reason why your decapping pin is getting stuck. I use a decapping pin with a smaller diameter, especially for these cases.

I'm fortunate on recapping pins. I use a Lee 40 S&W sizing die to decap and size the main body before running through the 357 SIG sizer. The 40s recapping pin is smaller diameter that most pins.Got everything set up, with some 124 grain berrys FP bullets as dummy rounds to get me close for when the actual projectiles get here. I went to deprime/size the brass, and my decapping pin keeps pulling out of the shaft and getting stuck in the case! I’ve got a Redding die set. Any suggestions?

Speer brass seems to have the smallest flash holes of any other brass headstamp.

Elkins45

Member

My go-to bullet is a 130 grain SWC from NOE because it has a nice long straight bearing surface. I size to .358 and I’ve never owned a 9mm or 357 Sig that wouldn’t chamber them. My .356 sizing die might as well be a paperweight.I'm giving serious thought to the .357 sig.

I'm curious whether anyone has tried a .357 dia lead SWC?

I don't want to hijack this thread - But it seems relevant to the OP anyhow

Slow powders are your friend when loading 357 Sig. Can’t get bullet setback if the case is already full.

Alex G

Member

- Joined

- Dec 30, 2020

- Messages

- 242

^This is literally EXACTLY what I ended up doing hahaI'm fortunate on recapping pins. I use a Lee 40 S&W sizing die to decap and size the main body before running through the 357 SIG sizer.

Grabbed my Lee 40 die, checked the cartridge OD specs in the load manual to make sure they were the same, and went for it. Worked perfect!

I generally lube all my pistol cases with lanolin (9, 40, 357 mag and SIG, 38 spl, etc...) before sizing while they are still dirty, so having the carbide sizer ring in the 40 die is an added perk to reduce wear on my steel 357 SIG sizer die as well. Then they go in the wet tumbler and come out clean, shiny, sized, and ready to load! The more ya know...

Here’s the first batch done and drying:

vaalpens

Member

- Joined

- Aug 14, 2014

- Messages

- 2,618

^This is literally EXACTLY what I ended up doing haha

Grabbed my Lee 40 die, checked the cartridge OD specs in the load manual to make sure they were the same, and went for it. Worked perfect!

I generally lube all my pistol cases with lanolin (9, 40, 357 mag and SIG, 38 spl, etc...) before sizing while they are still dirty, so having the carbide sizer ring in the 40 die is an added perk to reduce wear on my steel 357 SIG sizer die as well. Then they go in the wet tumbler and come out clean, shiny, sized, and ready to load! The more ya know...

Here’s the first batch done and drying:

Great looking brass!

I used to use my 40 sizing die, but not anymore. My process is now as follow:

- Deprime using the Lee universal depriming die. Cases then go into a ready to clean container until I have enough to clean/process.

- Wet tumble full container of 357sig cases (already deprimed), and then dry.

- Debulge cases using 40 Lee FCD. I use a bit of Unique case lube.

- Resize cases using Lee 357sig resizer die, while cases are still lubed. I handle the neck/shoulder with my hands to make sure I get some lube on the neck/shoulder.

- Wash the cases without any stainless steel pins, then dry.

- Now they are ready to load.

You did not say where you got your cases from, so hopefully they won't need any debulging.

Looking forward to see you first test results.

Alex G

Member

- Joined

- Dec 30, 2020

- Messages

- 242

Thanks!!Great looking brass!

This is actually what I had planned to do initially, except I realized that the decapping pin on my Mighty Armory universal decapper (the .074”) was too big for the flash holes....needless to say I’ve got some of the small pins en route now hahaDeprime using the Lee universal depriming die.

How important is it to debulge? So far, all cases that I’ve sampled after sizing have passed the plunk test just fine, and seated flush.Debulge cases using 40 Lee FCD.

If I’m reading correctly, I’m assuming just to remove lube because they have already been cleaned before during the first wet tumble step, correct?Wash the cases without any stainless steel pins, then dry.

Thanks! Definitely appreciate all the help and advice! Got some gold dot projectiles (designed for 357 sig) and some X-Treme 124 gr FP on the way as well.Looking forward to see you first test results.

- Status

-

Not open for further replies.

Similar threads

- Replies

- 8

- Views

- 927