mercervillerental

Member

- Joined

- Apr 7, 2017

- Messages

- 47

I'm fairly new to rifle reloading and running into an issue. It seems as though my AR is doing a fairly good job of scratching/gouging my brass at some point during the firing cycle.

For starters I'm not sure exactly what my load was for the cases I'll be posting examples of below as I had 70 rounds of 55gr VMAX and 69gr SMK with varying degrees of powder charges. The absolute hottest I went was 25.5gr of CFE223 under the 69gr SMK loaded at 2.250 COAL. I'm shooting out of a Stag Model 3 with a 16' barrel and 1:9 twist.

All of the brass is Federal Lake City that was from XM855 surplus rounds I purchased and fired originally out of the same rifle. All cases were trimmed to 1.75

I'll post images of each of the cases with some questions/comments on each one. I'd love to get everyone's collective thoughts and appreciate any advice.

Case 1: Seems like this might be a case neck split from a bit too hot of a load? While my hottest loads were on the high end of the load data from Hornady and Hodgdon for .223 loads this is a 5.56 chamber and brass so I wouldn't have expected this. Could this be something else?

Case 2: This does not appear to be a split as it doesn't go all the way through the brass. There are quite a few (70% maybe) other cases that have similar "scratches" in about the same area but I'm discarding this one as it seems to be a deeper scratch than the others. Would you do the same or would you reload it?

Case 3: Roughly the same as case 2 but more of a gouge than a scratch. Would you reload this?

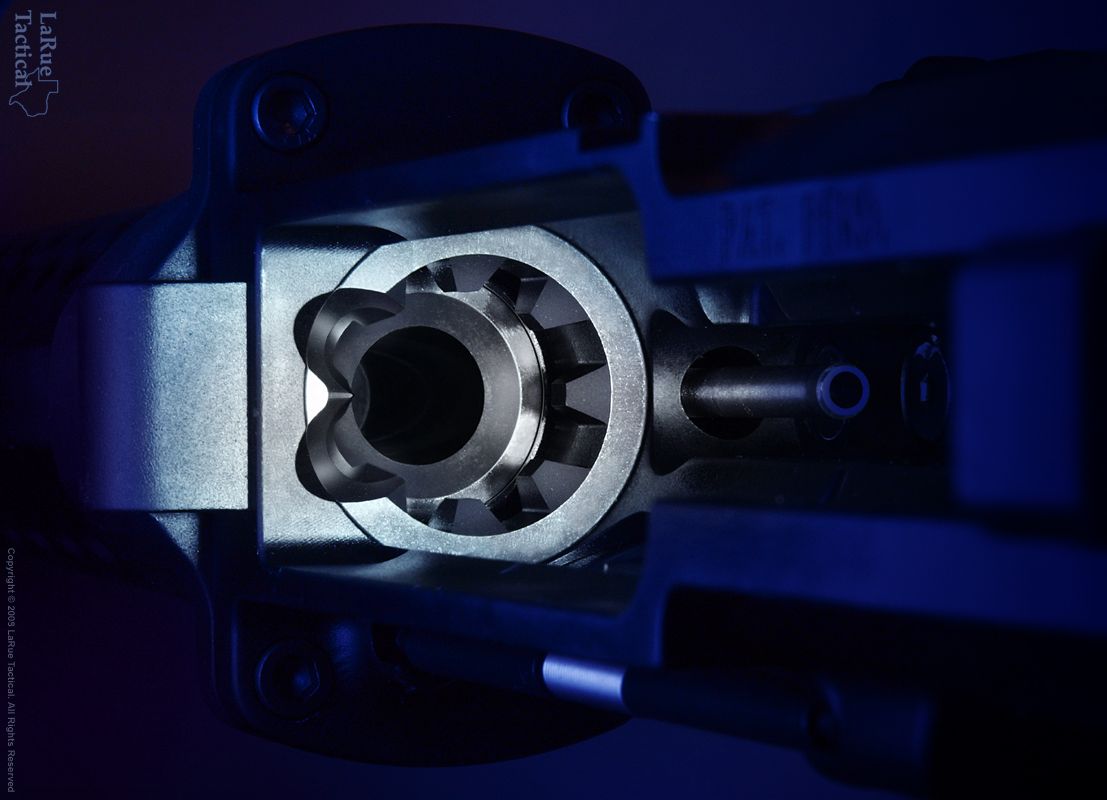

Overall is there anything I can do to avoid this type of brass damage? The brass never hits the concrete, I use a brass catcher. I've seen about 100 threads online ranging from "this is normal" to "replace your barrel" to "file your feed ramp" (along with many other possible issues/recommendations) and trying to make sense of it all.

Thanks again all!

For starters I'm not sure exactly what my load was for the cases I'll be posting examples of below as I had 70 rounds of 55gr VMAX and 69gr SMK with varying degrees of powder charges. The absolute hottest I went was 25.5gr of CFE223 under the 69gr SMK loaded at 2.250 COAL. I'm shooting out of a Stag Model 3 with a 16' barrel and 1:9 twist.

All of the brass is Federal Lake City that was from XM855 surplus rounds I purchased and fired originally out of the same rifle. All cases were trimmed to 1.75

I'll post images of each of the cases with some questions/comments on each one. I'd love to get everyone's collective thoughts and appreciate any advice.

Case 1: Seems like this might be a case neck split from a bit too hot of a load? While my hottest loads were on the high end of the load data from Hornady and Hodgdon for .223 loads this is a 5.56 chamber and brass so I wouldn't have expected this. Could this be something else?

Case 2: This does not appear to be a split as it doesn't go all the way through the brass. There are quite a few (70% maybe) other cases that have similar "scratches" in about the same area but I'm discarding this one as it seems to be a deeper scratch than the others. Would you do the same or would you reload it?

Case 3: Roughly the same as case 2 but more of a gouge than a scratch. Would you reload this?

Overall is there anything I can do to avoid this type of brass damage? The brass never hits the concrete, I use a brass catcher. I've seen about 100 threads online ranging from "this is normal" to "replace your barrel" to "file your feed ramp" (along with many other possible issues/recommendations) and trying to make sense of it all.

Thanks again all!