The new Pro 4000

View attachment 779279

We have asked for 4 station progressive press based on Classic Turret and looks like Lee Precision delivered with features from other presses (Code name "

Pro 4000"):

- 4 stations allow separate seat and crimp operation

- Auto Index Progressive for high volume operation (Disable auto index for single stage operation)

- Breech Lock with built-in lock ring for quick no-adjustment die change (4 comes with press)

- New case feeder design

- Through ram primer disposal and tube (No more pesky primers and ram/press stays cleaner)

- Large and small Safety Prime (No more primer feed attachment issues)

- Ergonomic roller handle (Allows left or right hand operation)

- Built-in storage rack with included hex wrench

With case collator (and drilled penny and 22LR spent case mod for 9mm/380 cases) and new case feeder design, this new 4 station progressive press has potential for serious volume reloading (pistol and short rifle calibers).

With off-set ram under Station 1, looks like Lee Precision may have worked on reducing shellplate tilt issue when resizing overly expanded brass for more consistent OAL/COL variance. (See last detail picture below).

Most progressive presses mount ram in the center of shellplate and during resizing, depending on the force required to resize the brass in Station 1, shellplate tilt can contribute to OAL variance on bullet seat/crimp stations 3/4 or 4/5 depening on 4 or 5 station press. For this reason, I used separately resized brass for my USPSA match loads for more consistent OAL variance.

Definitely looking forward to testing the new Pro 4000.

Built-in storage rack for spare primer arm and hex wrench.

View attachment 779280

Breech Lock with built-in lock ring

View attachment 779281

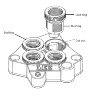

4 Station shellplate carrier with clockwise rotation (loaded rounds discharge to the right side of press).

- Station (right front) with new case feeder

- Station (left front) for Safety Prime and flare/powder thru charging

- Station (left back) for bullet seating

- Station (right back) for bullet crimping

Allows right hand to operate the ergo handle while left hand to set bullets in Station 3 (Picture shows Station 1 with long case feed slider at 2 O'clock position)

View attachment 779282

Left or right side mounting of ergo roller handle. Off-set ram under Station 1 (right front) to address shellplate tilt when sizing overly expanded brass and produce more consistent finished OAL/COL.

View attachment 779283