WestKentucky

Member

The technology is here, and it’s getting cheaper and cheaper. I know there are a few members who 3D print reloading items like primer catchers, and I’m sure there are others making various doodads. Let’s see your handy work!

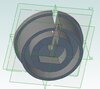

Make sure it stays firearm related though because if we delve off into hardware and software discussions we will get shut down. I’m still learning to use the modeling software but I will be printing soon. A few tweaks to my first few files will produce 2 wheels, a limber, and a small mountain howitzer. Hopefully by Christmas…

Make sure it stays firearm related though because if we delve off into hardware and software discussions we will get shut down. I’m still learning to use the modeling software but I will be printing soon. A few tweaks to my first few files will produce 2 wheels, a limber, and a small mountain howitzer. Hopefully by Christmas…