Hi,

I am curious about pressure curve for my 16" barreled 30-30 that I had chopped from 20".

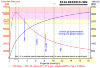

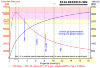

Would like to get a chart like the following out to 16", for a typical 30-30 factory load with 170gr projectile. You are free to make up whatever velocity and powder values to get a representative pressure.

I would like one for the Remington 170 gr Core-Lokt® Centerfire round or similar typical factory round.

30-30 Win.

170gr

2200 FPS

Tried to download and run the quickload demonstration version, but can not get it to work for the life of me!!! :banghead:

Thanks!

I am curious about pressure curve for my 16" barreled 30-30 that I had chopped from 20".

Would like to get a chart like the following out to 16", for a typical 30-30 factory load with 170gr projectile. You are free to make up whatever velocity and powder values to get a representative pressure.

I would like one for the Remington 170 gr Core-Lokt® Centerfire round or similar typical factory round.

30-30 Win.

170gr

2200 FPS

Tried to download and run the quickload demonstration version, but can not get it to work for the life of me!!! :banghead:

Thanks!