bczrx

Member

Hi,

My Question: Is Headspace ALWAYS set with changing the barrel/chamber? Or, is there anything that can be safely done to the bolt to add about .002 of headspace to a rifle?

Situation:

I have a Remington-made 1903 from May of 1942 [NOT a 1903A3].

Long story short, I also have another bolt that I was testing to see if it fit [call it B].

My 'smith said that to make [bolt B] fit, the barrel would have to have the chamber reamed about .002-003.

Yet, if I did that, then Bolt A would be over the NoGo size, and nearing/passing the Field Gauge safety specs.

This leads me to the original question above.

I was thinking [always dangerous]...

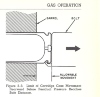

Is it possible to remove about .001-.002 from the back side of the bolt locking lugs, so that it sits that much toward the rear, and allows that increase in headspace?

or, is this a huge no-no.

Any help is appreciated. I would love to have another Remington marked bolt that fits as a backup.

thank you.

My Question: Is Headspace ALWAYS set with changing the barrel/chamber? Or, is there anything that can be safely done to the bolt to add about .002 of headspace to a rifle?

Situation:

I have a Remington-made 1903 from May of 1942 [NOT a 1903A3].

- The bolt [call it A] has a good fit. It doesn't close on No-Go gauge,

- closes well on Go Gauge.

- No need for Field gauge.

Long story short, I also have another bolt that I was testing to see if it fit [call it B].

- It has more resistance than optimal with 'go' gauge,

- and NoGo won't close more than half-way.

My 'smith said that to make [bolt B] fit, the barrel would have to have the chamber reamed about .002-003.

Yet, if I did that, then Bolt A would be over the NoGo size, and nearing/passing the Field Gauge safety specs.

This leads me to the original question above.

I was thinking [always dangerous]...

Is it possible to remove about .001-.002 from the back side of the bolt locking lugs, so that it sits that much toward the rear, and allows that increase in headspace?

or, is this a huge no-no.

Any help is appreciated. I would love to have another Remington marked bolt that fits as a backup.

thank you.