Hoss Smith

Member

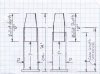

I use an RCBS press and dies from the sixties the press resembles todays rock chunker. The issue I am having is inconsistency with the OAL. I have the die screwed down tighter than Dick's hatband and I take the ram to the top on each stroke but I get varying over all lengths. I quit adjusting the bullet seater when I realized that it had to stay put if everything was tight and I will get a number of fairly consistent rounds but they are not all the same. I have measured the bullets (ancient Speer 100 grain SP) and they are a very consistent length some of my cases vary in length but I am not thinking that would affect the OAL of a loaded round account the length from the case seat to the bullet seat ought not to vary. I have a round here in front of me that measures out at 1.691" when I am attempting to achieve a consistent 1.680". I showed it to one of my carbines and it refused to swallow it.

I need some advice from y'all that will get me going. Please use short words and don't assume I know much account I may miss your point.:banghead:

I need some advice from y'all that will get me going. Please use short words and don't assume I know much account I may miss your point.:banghead: