Click_Here

Member

- Joined

- Oct 19, 2022

- Messages

- 138

Im going to have to go dig up some GFL's I got. I havent had a problem with those... IK 21 on the other hand, i have to thank for making sure I now have a handful of spare decapping pins.

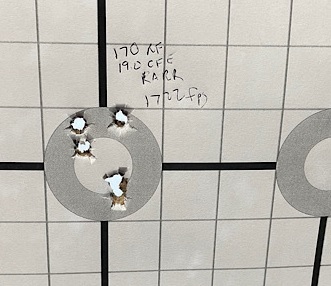

This is a test target. 50 yards off a bench with a Palmetto State Armory 300BO with a 10.5" barrel.I just bought re-done Lake City and Starline brass... along with Berrys plated 220 grain bullets.

However, I've been shooting my 9mm AR more than anything. Loading 9mm with RMR 147 grain FMJ RN is cheap and easy. 3.8 grains of HP38/W231 at 1.14" OAL shoots great in both the pistol and carbine, and is still subsonic in both.

Getting the itch to shoot the 300BO more. Found that 10.5 grains of 4227 behind the 220 grain bullet works great subsonic, has consistent velocities and is also the most accurate of what I've tried with my 10.5" barrel. Some powders didn't have consistent velocities and accuracy until they were supersonic. H110/W296 for example.

I ended up (even though my chambers neck was generous), culling thick necked converted cases.The wise man has spoken.

Way way back in the day, I converted 1,000's of .223

Chop, deburr, size, trim, deburr....

Only brass that was too thick to chamber after conversion was S&B.

Fast forward to modern times.... Just buy it.

I have found LC, FC, A USA, GECO, & Perfecta are ones that have converted with the right wall thickness and that fit the Lyman's case gage.Since you're building an "upper" and depending on the barrel you choose you might be able to get away without neck turning, AR 300 blk chambers are generally more forgiving. I've converted thousands of 223/556 cases to .300 BLK but stuck to the following brass without issues. PSO, PMC (Large Font), LC (Any), R-P, GFL.

My process. Cut to a length where I will not need to trim after sizing, Chamfer/Debur, Tumble, Resize/Form to 300 BLK, Tumble again to get the lube off.