dredd

Member

Ref.

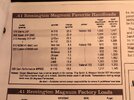

41 Remington Magnum

Ruger NMBH

215/gr LSWC

Does anyone know of any other Published Sources besides Hodgdon?

They list one load that uses AA#9, which I'll already be using to load the Hornady 210/gr XTP's.

Manuals in hand are Hornady, Lyman and Sierra. (No Help on this bullet)

I'm curious if there are other powder options for this particular bullet.

I am not opposed to purchasing another manual.

For those that will ask why this bullet?

I can get these Hi-Tek Coated for $0.132/ea delivered.

Thanks!

Dredd

41 Remington Magnum

Ruger NMBH

215/gr LSWC

Does anyone know of any other Published Sources besides Hodgdon?

They list one load that uses AA#9, which I'll already be using to load the Hornady 210/gr XTP's.

Manuals in hand are Hornady, Lyman and Sierra. (No Help on this bullet)

I'm curious if there are other powder options for this particular bullet.

I am not opposed to purchasing another manual.

For those that will ask why this bullet?

I can get these Hi-Tek Coated for $0.132/ea delivered.

Thanks!

Dredd