grizz

Member

Well, I guess I'll probably just keep it until it gives me problems, then decide what to do. I've only put about 200 rounds through it and it's been flawless so far.

Thanks everyone.

Thanks everyone.

From what I understand, the AR does have a little primary extraction, but not much. We also have to remember that the AK has no primary extraction as well. So it is not the lack of PE that is the problem, but other factors.

The AK uses a very large and powerfull extractor to grip the case and pull it out. The AR extractor is small compared to the AK extractor. The AK uses the massive bolt carrier and bolt to "store" the energy given to it by the gas pressure while the AR relies more on the gas volume given to it by the gas tube.

taliv said:rolling your own upper

highorder said:Correct me if I'm wrong, but the carbine gas system was designed for a 10" or 11" barrel.

45B@cav said:I don't mean to get of subject but I would not do the whole extracter upgrade with the O-ring thing. On my last deployment I had 2 cotractors carbines come in with bolts broken off at the extracter pin. Both had O-ring around the spring. I replaced them with the upgraded springs and warned against doing it again the contractor didn't have anymore problems after the fix. Has anyone else heard of this happening?

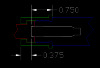

Dr. Tad Hussein Winslow said:What's the longest and shortest barrel found with mid-length systems - i.e. what's the range of possible working barrel lengths?

Off the cuff, I would say that the difference is not as simple as reciprocating mass. That's a component of it, of course, but qually important would be things like where is the reciprocating mass? In the AR it is all in direct line with the bore and the shoulder. In the AK it sits above the bore, which in turn sits above the shoulder.The moving mass in the AR and AK is very close so you might as well give eup on the whole 'massive bolt carrier' thing. BSW

The writer sounds astute until this point. Unlocking doesn't really start until the bullet has left the barrel and pressures are way down, near zero.

The carbine bolt may start faster, but it starts venting faster too.

If the gas was having a 50% greater impact on bolt carrier speed, the cyclic rate would surely be much higher on the M4.